heavy alloy tungsten threaded electrode High kuoma uye density

Kugadzirwa kwe tungsten threaded electrode kunosanganisira akati wandei matanho akakosha kuti ave nechokwadi chepamusoro-soro, chinogara chigadzirwa. Izvi zvinotevera mhedziso yezvakajairwa nzira dzekugadzira tungsten threaded electrodes:

1. Kusarudzwa kwezvinhu zvakasvibirira: Maitiro anotanga nekusarudza emhando yepamusoro tungsten zvinhu. Tungsten inozivikanwa nekuoma kwayo kwakasarudzika uye nzvimbo yakakwira yekunyungudika, ichiita kuti ive yakanakira maelectrodes akarukwa uko kusimba uye kuramba kupisa kunodiwa.

2. Kugadzirira kwehupfu: Gadzira tungsten yakasarudzwa yakasvibiswa muupfu hwakatsetseka kuburikidza nekuderedza hydrogen kana ammonium paratungstate (APT) kuderedza. Upfu uhu ndicho chinhu chikuru chekugadzira ma threaded electrode.

3. Kusanganisa uye kubatanidza: Tungsten hupfu inosanganiswa nezvimwe zvinhu zvealloying kuti uwane zvinhu zvinodiwa, zvakadai sekuwedzera kuoma uye kusimba. Hupfu hwakasanganiswa hunobva hwatsindirwa muchimiro chaidiwa pachishandiswa nzira dzekutsikirira dzepamusoro-soro dzakadai sekutonhora isostatic pressing (CIP) kana kuumba.

4. Sintering: Iyo compacted tungsten powder inokonzerwa nepamusoro-tembiricha sintering mumhepo inodzorwa (kazhinji mune vacuum kana hydrogen environment). Sintering inobatsira kusunga tungsten zvidimbu pamwechete kuti zvigadzire chimiro chakakora uye chakasimba.

5. Machining uye threading: Mushure mekunyunguduka, tungsten zvinhu zvinogadzirwa kusvika pakukura kwekupedzisira uye zvakarukwa kuti zvigadzire chimiro chinodiwa che electrode. Precision machining tekinoroji inoshandiswa kuve nechokwadi chechokwadi chetambo maficha.

6. Kurapwa kwepamusoro: Maelectrode akaiswa shinda anogona kurapwa pamusoro senge kukuya, kupukuta kana kupeta kuti awedzere kushanda kwawo pamwe nekupfeka uye kusagadzikana kwemarara.

7. Kudzora Kwehutano: Mukati mese maitiro ekugadzira, matanho ekugadzirisa hutano anoshandiswa kuti ave nechokwadi chokuti ma electrode akaiswa mu thread anosangana nekuoma kunodiwa, density, dimensional accuracy uye mamwe anokosha parameter tsanangudzo.

Nekutevera aya matanho ekugadzira, vagadziri vanogona kugadzira tungsten threaded maelectrode ane kuomarara kwakanyanya, density uye kusimba, zvichiita kuti ive yakakodzera kune inoda kunyorera mumaindasitiri akadai sewelding, simbi uye magetsi discharge machining (EDM).

Tungsten threaded electrodes inoshandiswa mumhando dzakasiyana-siyana dzemaindasitiri nekuda kwekuoma kwazvo, kusimba uye kusimba. Mamwe maapplication akajairika anosanganisira:

1. Resistance welding: Tungsten threaded electrodes inoshandiswa mukupikisa welding process semapoinzi ekusangana kuitisa ikozvino uye kugadzira kupisa kubatanidza zvikamu zvesimbi. Kuomarara kweTungsten kwakakwira uye kupikisa kupisa kunoita kuti ive yakakodzera kumirisana nekupisa kwepamusoro uye kushushikana kwemakinari kunosangana mukupikisa welding mashandiro.

2. Electric Discharge Machining (EDM): MuEDM, tungsten threaded electrodes inoshandiswa sezvishandiso zvekugadzira uye machining conductive zvinhu. Kuoma kweTungsten uye kupfeka kuramba kunoita kuti ive sarudzo yakanaka yekugadzira zvikamu zvakaoma zvemuchina kuburikidza neiyo EDM maitiro.

3. Spark corrosion: Tungsten threaded electrodes inoshandiswa mu spark corrosion kana molding process se electrode zvinhu zvekugadzira zvimiro zvakaoma uye maficha pasimbi workpieces. Tungsten's high density uye thermal conductivity inogonesa kubviswa kwezvinhu zvakanaka uye kunyatsogadzira machining mune spark erosion application.

4. Metal Forming and Stamping: Tungsten threaded electrodes inoshandiswa mukugadzira simbi uye kutsika mabasa kubatsira kuumba, kubaya kana kucheka simbi mashizha uye zvikamu. Kuoma kweTungsten uye kusimba kunoita kuti ive yakakodzera kumirisana nemasimba emagetsi anobatanidzwa mukugadzira simbi.

5. Girazi uye Ceramic Processing: Tungsten threaded electrodes inoshandiswawo mugirazi uye ceramic processing application yekuchera, kucheka kana kuumbwa kwezvinhu izvi zvinoputika. Kuomarara kweTungsten uye kupfeka kuramba kunoita kuti ive yakakodzera kune chaiyo machining mugirazi uye maindasitiri eceramic.

6. Aerospace uye Dziviriro: Tungsten threaded electrodes inoshandiswa mumhando dzakasiyana-siyana dzekugadzira nekugadzirisa maitiro munzvimbo yeaerospace uye yekudzivirira, kusanganisira welding, machining uye kugadzirwa kwesimbi, izvo zvinoda kushanda kwepamusoro uye zvigaro zvekushandisa zvakasimba.

Pakazere, kuomarara kwepamusoro, kusimba, uye kusimba kwema tungsten akarukwa maelectrode anoita kuti anyatso kukodzera kune akasiyana siyana maindasitiri ekushandisa, kunyanya maitiro anosanganisira kupisa kwakanyanya, kushushikana kwemechini, uye chaiyo machining zvinodiwa.

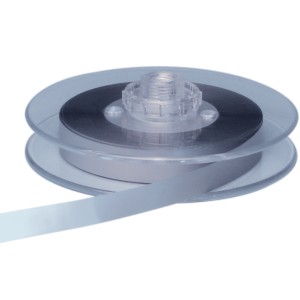

| Product Name | Tungsten Threaded Electrode |

| Material | W1 |

| Tsanangudzo | Customized |

| Surface | Ganda dema, alkali yakashambidzwa, yakakwenenzverwa. |

| Technique | Sintering process, machining |

| Meltng point | 3400 ℃ |

| Density | 19.3g/cm3 |

Wechat:15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com