99.95% Molybdenum flange Inoshandiswa pakubatanidza pombi

Kugadzirwa kwe99.95% molybdenum flanges kunosanganisira matanho akakosha ekuona kunaka, kurongeka uye kukodzera kwekubatanidza pombi mumhando dzakasiyana dzemaindasitiri. Izvi zvinotevera mhedziso yenzira yekugadzira ye99.95% molybdenum flange:

1. Kusarudzwa kwezvinhu: Nhanho yekutanga mukugadzira molybdenum flanges ndeyekusarudza yakakwirira-kuchena molybdenum zvinhu. Zvishandiso zvinofanirwa kusangana nematanho ekuchena akatsanangurwa, anowanzo 99.95%, kuve nechokwadi chezvivakwa zvinodikanwa senge kuramba kutonhora kwakanyanya uye ngura. Molybdenum zvinhu zvinotorwa kubva kune vane mukurumbira vatengesi kuti ive nechokwadi chekuchena kwavo uye kuenderana.

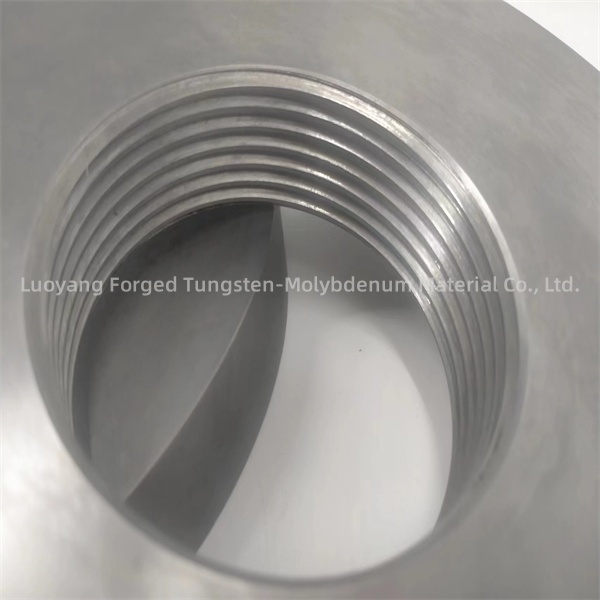

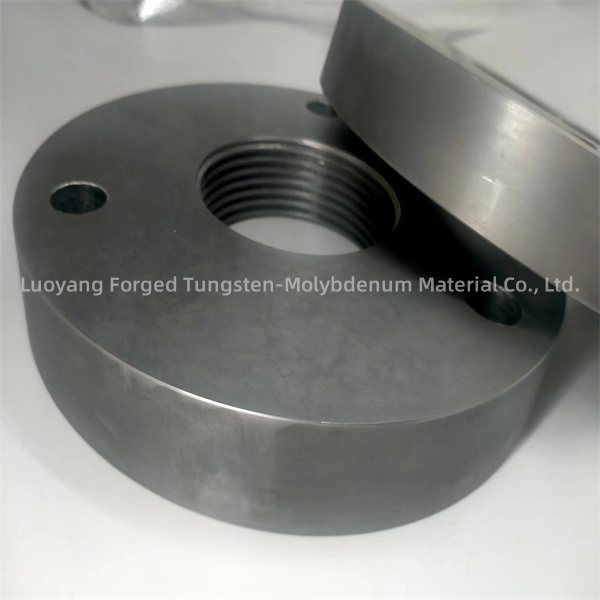

2. Kugadzira uye kugadzira: Precision machining tekinoroji inoshandiswa kugadzirisa iyo molybdenum zvinhu kuita flange. Izvi zvinogona kusanganisira CNC (kombuta nhamba yekudzora) kugaya, kutendeuka kana mamwe machining maitiro ekuumba molybdenum mune inodiwa flange kumisikidzwa. Kunyatsogadzira machining kwakakosha kuti uve nechokwadi chehukuru chaihwo uye kupera kwepamusoro kweflange.

3. Kubatanidza uye Welding: Mune zvimwe zviitiko, molybdenum flanges ingada kujoinha kana kuti welding kuti iite chikamu chekupedzisira. Nyanzvi welding matekiniki akakodzera molybdenum, senge erekitironi beam welding kana laser welding, inogona kushandiswa kuve nechokwadi chechimiro chekuvimbika kweflange uye kuchengetedza hunhu hwayo hwakachena.

4. Kurapa kwepamusoro: Zvichienderana nezvinodiwa zvechikumbiro, molybdenum flanges inogona kugadziriswa pamusoro kuti iwedzere kushanda kwavo. Izvi zvinogona kusanganisira maitiro akadai sekupukuta, passivation kana coating kuti uvandudze kudzivirira kweflange pakuora uye kupfeka.

5. Kudzora kwehutano: Mukati mekugadzirwa kwezvinhu, matanho akasimba ekugadzirisa maitiro anoshandiswa kuti aone kurongeka kwedimensional, kunaka kwepamusoro uye kuvimbika kwezvinhu zve molybdenum flange. Izvi zvinogona kusanganisira kushandiswa kwemidziyo yekuongorora yepamusoro senge kurongeka kwemachina ekuyeresa (CMM) uye nzira dzisiri dzekuparadza dzekuyedza kuona kuti flange inosangana nezvinodiwa.

6. Kuongorora kwekupedzisira uye kurongedza: Mushure mokunge molybdenum flange yagadzirwa uye inoshandiswa, ichaita kuongororwa kwekupedzisira kuti ione kuti inosangana nemitemo yakasimba yekubatanidza pombi. Izvi zvinosanganisira kuongorora zviyero zveflange, kupera kwepamusoro uye huwandu hwese. Mushure mekuongorora kwakabudirira, iyo flange ichave yakanyatsorongedzwa kuti ichengetedze panguva yekufambisa uye kuchengetedza.

Izvo zvakakosha kuti uzive kuti nzira dzekugadzira dze99.95% molybdenum flanges dzinofanira kutevedzera indasitiri mirau uye zviyero, kusanganisira izvo zvine chekuita nekuchena kwezvinhu, kuchena uye kurongeka kwechimiro. Pamusoro pezvo, nzvimbo dzekugadzira dzinofanirwa kuchengetedza nzvimbo yakachena uye inodzorwa kudzivirira kusvibiswa kweflange.

99.95% Molybdenum flanges ine akasiyana-siyana ekushandisa, uye nekuda kweiyo yakasarudzika midziyo ye molybdenum, inowanzoshandiswa munzvimbo dzakasiyana dzeindasitiri. Heano mamwe akakosha maapplication e99.95% molybdenum flanges:

1. Kupisa kwepamusoro uye nharaunda inoora: Molybdenum flange inoshandiswa mumaindasitiri umo tembiricha yepamusoro uye nharaunda inoparadza zvakajairika. Semuenzaniso, mukugadzirwa kwemakemikari, kunatsa uye kugadzirwa kwesimbi, molybdenum flanges anoshandiswa mukubatanidza pombi kuti amire kutonhora kwakanyanya uye kuramba ngura kubva kumakemikari ane hutsinye.

2. Vacuum systems uye aerospace applications: Molybdenum flanges inokosha zvikamu muvacuum systems, kusanganisira iyo inoshandiswa mune aerospace, semiconductor kugadzira uye nzvimbo dzekutsvakurudza. Nzvimbo yavo yepamusoro yekunyungudika uye kuramba kubuda kunze kunoita kuti vakwanise kugadzira zvisimbiso zvakavimbika mumakamuri ekutsvaira uye nzvimbo dzakakwirira dzekutsvaira.

3. Simba neNuclear Applications: Molybdenum flanges inogona kushandiswa mumashandisirwo ane chokuita nemagetsi, kusanganisira zvigadziro zvemagetsi enyukireya, zvigadziridzo zvekutsvakurudza uye zvimwe zvivako uko kupikisa kwekushisa kwepamusoro uye kuvimbika kwakakosha. Iwo anoshandiswa mukubatanidza pombi inotakura kupisa kwakanyanya kwemvura uye magasi munzvimbo idzi dzinoda.

4. Semiconductor uye zvigadzirwa zvemagetsi: Molybdenum flanges inhengo inokosha ye semiconductor uye magetsi ekugadzira maitiro, kunyanya mu-ultra-high vacuum (UHV) nzvimbo. Iwo anoshandiswa kuvaka vacuum uye gasi kuburitsa masisitimu, kuve nechokwadi chekubatana kwakavimbika mumatanho akakosha akadai seyakaonda firimu deposition uye semiconductor kugadzira.

5. High-pressure systems: Molybdenum flanges inoshandiswa mumagadzirirwo epamusoro-soro, akadai seaya ari mumakemikari uye petrochemical industries, kwaanopa hutano hwakachengeteka uye hunogara huripo hwemapaipi anotakura gasi rinoputika uye zvinwiwa.

6. Tsvagiridzo neKuvandudza: Molybdenum flanges anoshandiswa munzvimbo dzekutsvagisa nekusimudzira, kusanganisira marabhoritari uye nzvimbo dzekuyedza, michina yakasarudzika yekupisa kwepamusoro, kudzvanywa kwakanyanya uye vacuum application.

Mune zvese izvi zvikumbiro, hunhu hwepamusoro hwemolybdenum, hunosanganisira kupisa kwakanyanya kwekushisa, kusagadzikana kwecorrosion uye simba remagetsi, inoita 99.95% molybdenum flanges chinhu chakakosha mukuona kuvimbika uye kuvimbika kwekubatanidza pombi munzvimbo dzakaoma dzeindasitiri. Pamusoro pezvo, iwo chaiwo ekugadzira uye emhando yekudzora maitiro anosanganisirwa mukugadzira molybdenum flanges inova nechokwadi chekuti inosangana nezvinodiwa zvakaomesesa zvezvavanoda kuita.

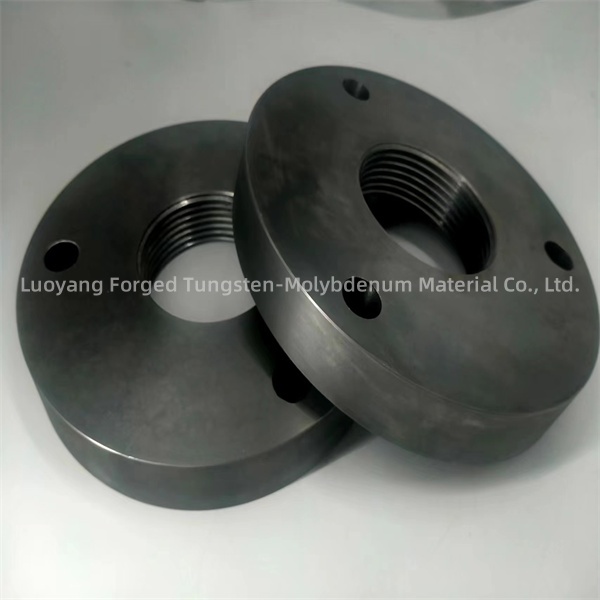

| Product Name | 99.95% Molybdenum Flange |

| Material | Mo1 |

| Tsanangudzo | Customized |

| Surface | Ganda dema, alkali yakashambidzwa, yakakwenenzverwa. |

| Technique | Sintering process, machining |

| Meltng point | 2600 ℃ |

| Density | 10.2g/cm3 |

Wechat:15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com