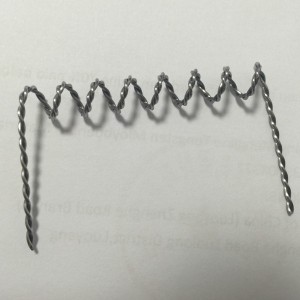

tungsten uye molybdenum waya Evaporation coils

Tungstenevaporation coils

Kuchena : W ≥ 99.95%

Mamiriro epamusoro: Kemikari yakacheneswa kana electrolytic polishing.

Melt point: 3420 ± 20 ℃

Saizi: zvinoenderana nemufananidzo wakapihwa.

Type: Yakatwasuka, U chimiro, V chimiro, Basket.Helical.

Kushandisa: Tungsten waya heaters inonyanya kushandiswa kupisa zvinhu zvakadai sepikicha chubhu, girazi, plastiki, simbi substrate, ABS, PP uye zvimwe zvepurasitiki zvinhu pamusoro pezvakasiyana zvekushongedza zvinhu. Tungsten waya inonyanya kushandiswa seyakagadzirwa zvinhu kune hita.

kushanda musimboti: Tungsten ine yakakwira kunyungudika, yakakwira magetsi resistivity, simba rakanaka uye yakaderera mhute pressure, ichiita kuti ive yakakodzera kushandiswa sehita. Iyo membrane inoiswa mumudziyo mukamuri yevacuum, uye inopisa pasi pemamiriro epamusoro ekuputira nemoto (tungsten heater) kuti ibude. Kana iyo nzira yemahara yemamorekuru emhupo yakakura kupfuura mutsara saizi yekamuri yekutsvaira, maatomu emhute Mushure mekunge mamorekuru apukunyuka kubva pamusoro peiyo sosi yekubuda, haawanzo kukanganiswa kana kudziviswa nemamwe mamorekuru kana maatomu, uye inogona kusvika zvakananga pamusoro peiyo substrate inofanira kuiswa. Pamusana pekushisa kwepasi kwe substrate, iyo firimu inoumbwa ne condensation.

Thermal evaporation (resistance evaporation) inzira yekuputira inoshandiswa sechikamu chePVD process (Physical Vapor Deposition). Iyo midziyo yekugadzira iyo inotevera layer inodziya muvacuum chamber kusvika yabuda. Iyo mhute inoumbwa nezvinhu inodzika pa substrate uye inoita iyo inodiwa layer.

Macoil edu evaporation anoziva nzira yekusimudza kupisa: Aya maheater ekupikisa ane nzvimbo dzawo dzakanyanya kunyungudika achaunza chero simbi kumota. Panguva imwecheteyo, kupikisa kwavo kwepamusoro uye kuchena kwezvinhu zvinodzivirira chero kusvibiswa kwe substrate.