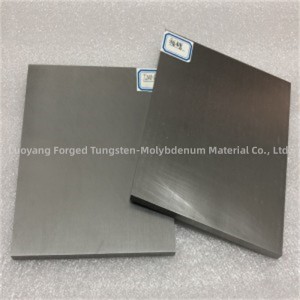

Yakagadzirirwa Mo La Alloy Plate YeIndustrial Furnace Outlet

Kugadzirwa kwe molybdenum-lanthanum (Mo-La) alloy sheets kazhinji kunosanganisira nhevedzano yekugadzira maitiro. Aya maitiro anogona kusanganisira: Raw material kugadzirira:

Danho rekutanga rinosanganisira kuwana zvinodiwa mbishi, senge molybdenum uye lanthanum, muchimiro chehupfu kana zvimwe zvakakodzera mbishi. Izvi zvigadzirwa zvakasarudzwa zvinosarudzwa zvichienderana nekuchena kwavo uye inodiwa alloy kuumbwa. Kusanganisa uye Kusanganisa: Molybdenum uye lanthanum hupfu zvinosanganiswa pamwe chete muzvikamu chaizvo kuti uwane inodiwa alloy kuumbwa. Iko kusanganiswa kunosanganiswa zvakakwana kuti ive nechokwadi chekugoverwa kwezvigadzirwa. Compaction: Musanganiswa wehupfu wakasanganiswa unobva wapetwa pasi pekumanikidzwa kwakanyanya kuita muviri wakasvibira uye wakabatana. Compaction inogona kuwanikwa uchishandisa matekiniki akadai sekutonhora isostatic pressing (CIP) kana uniaxial pressing. Sintering: Muviri wakasvibira wakanyungudutswa muchoto chepamusoro-soro pasi pemhepo inodzorwa kuti iwane yakasimba-state diffusion bonding pakati pe molybdenum ne lanthanum particles. Iyi nzira inoguma mukuumbwa kwedense uye yakanyatsobatanidzwa Mo-La alloy zvinhu. Kupisa kutenderedza: Iyo sintered Mo-La alloy zvinhu zvinozoiswa kune inopisa kukungurutswa maitiro kuti iwane ukobvu hunodiwa uye michina zvivakwa. Iyo inopisa yekutenderedza maitiro inosanganisira kupfuudza zvinhu kuburikidza neakatevedzana ma rolls pakudziya kwakanyanya kudzikisa ukobvu hwayo uye kugadzirisa microstructure yayo. Annealing: Mushure mekupisa kupisa, iyo Mo-La alloy ndiro inogona kuita annealing maitiro ekubvisa kushushikana kwemukati uye kuwedzera kunatsiridza microstructure yayo. Annealing inowanzoitwa pane imwe tembiricha uye kwenguva inodzorwa. Kurapa Kwepamusoro uye Kupedzwa: Mahwendefa eMo-La alloy anogona kuita mamwe marapirwo epamusoro senge pickling, machining kana kupukuta kuti uwane iyo inodiwa kupera kwepamusoro uye kushivirira. Kudzora kwemhando uye kuyedza: Munguva yese yekugadzira, Mo-La alloy mashiti anoteera emhando yekudzora matanho uye kuyedzwa kuti ave nechokwadi chekuti michina yavo, microstructure uye kuumbwa kwemakemikari zvinosangana nezvinodiwa.

Idzi nzira dzekugadzira dziri pamusoro ndedzekutarisa uye dzinogona kusiyana zvichienderana nehunyanzvi hwekugadzira uye michina inoshandiswa nevagadziri vakasiyana. Iwo chaiwo matanho uye ma paramita anosanganisirwa mukugadzirwa kweMo-La alloy sheets zvinoenderana nezvinhu zvakaita seinodiwa saizi yeshizha, michina zvivakwa uye kupera kushandiswa.

Molybdenum-lanthanum (Mo-La) alloy sheets anoshandiswa mune akasiyana maindasitiri ekushandisa nekuda kweayo akasiyana zvivakwa. Mahwendefa eMo-La alloy anozivikanwa nokuda kwesimba rawo repamusoro-tembiricha, yakanaka yekupisa conductivity, kupisa kutyisa kupikisa uye yakanakisa machinability. Izvi zvivakwa zvinogadzira Mo-La alloy mahwendefa akakodzera kune yakakwira tembiricha nharaunda uye inoda maapplication akadai se:

Zvikamu zvevira: Mo-La alloy mashiti anoshandiswa mukuvaka mavira indasitiri nemidziyo yekupisa kupisa nekuda kwekugona kwavo kutsungirira tembiricha yakakwira uye bhasikoro rinopisa. Indasitiri yeAerospace: Mahwendefa eMo-La alloy anoshandiswa muzvikamu zvemuchadenga, zvinosanganisira maroketi nozzles, makamuri ekupisa uye zvimwe zvinopisa-tembiricha zvimiro. Indasitiri yegirazi: Mashizha eMo-La alloy anoshandiswa mukugadzira girazi, kunyanya mukugadzirwa kwegirazi mold, zvinosimudzira uye tank reinforcements nekuda kwekupokana kwavo negirazi rakanyungudutswa uye kuvhunduka kwemafuta. Radiators uye Heat Exchangers: Mo-La alloy mahwendefa anoshandiswa mukupisa manejimendi maapplication anosanganisira ekupisa sinks emidziyo yemagetsi uye ekutsinhanisa kupisa kwepamusoro-tembiricha maitiro. Sputtering target: Mo-La alloy plate inoshandiswa senzira yekupopotera kune yakaonda firimu deposition mune semiconductor uye zvemagetsi kugadzira. Magetsi Mabatiro: Mo-La alloy mahwendefa anoshandiswa mumagetsi mabatiro uye masekete madhiza nekuda kwekunaka kwemagetsi conductivity uye kuramba kukukurwa kwearc. Zvekurapa uye Nuclear Zvishandiso: Mo-La alloy mashiti anoshandiswa mukudzivirira mwaranzi uye tembiricha yepamusoro muindasitiri yezvokurapa neyenyukireya.

Pakazere, Mo-La alloy mashizha anokosheswa nekubatanidzwa kwawo kwepamusoro-tembiricha simba, kupisa kwemhepo, uye kuramba kune dzakaomarara nharaunda, zvichiita kuti zvive zvakakosha munzvimbo dzakasiyana dzeindasitiri.

Wechat:15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com