Kub kub polished molybdenum vajvoog molybdenum lub hom phiaj rau kev lag luam daim ntawv thov

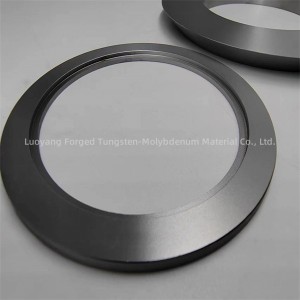

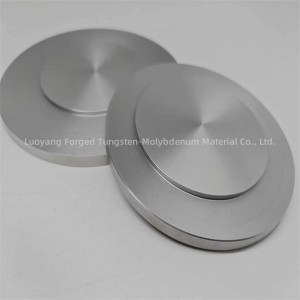

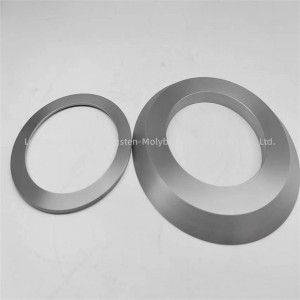

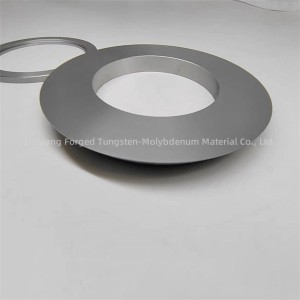

Molybdenum lub hom phiaj cov khoom siv yog cov khoom lag luam feem ntau siv hauv cov khoom siv high-tech xws li semiconductor manufacturing, nyias zaj duab xis deposition technology, photovoltaic kev lag luam, thiab cov khoom siv kho mob. Nws yog tsim los ntawm high-purity molybdenum, nrog lub siab melting point, zoo hluav taws xob thiab thermal conductivity, uas ua rau molybdenum lub hom phiaj kom nyob ruaj khov nyob rau hauv qhov kub thiab txias ib puag ncig. Lub purity ntawm molybdenum lub hom phiaj cov ntaub ntawv yog feem ntau 99.9% los yog 99.99%, thiab specifications muaj xws li lub hom phiaj, phaj phiaj, thiab rotating lub hom phiaj.

| Qhov ntev | Raws li koj xav tau |

| Qhov Chaw Keeb Kwm | Henan, Luoyang |

| Hom Lub Npe | FGD |

| Daim ntawv thov | Kev kho mob, kev lag luam, semiconductor |

| Cov duab | Hloov |

| Nto | Polished |

| Purity | 99.95% Min |

| Khoom siv | Ntshiab Mo |

| Qhov ntom | 10.2g / cm3 |

| Cov khoom tseem ceeb | Mo ≥ 99.95% |

| Cov ntsiab lus impurity ≤ | |

| Pb | 0.0005 |

| Fe | 0.0020 Nws |

| S | 0.0050 Nws |

| P | 0.0005 |

| C | 0.01 ib |

| Cr | 0.0010 Nws |

| Al | 0.0015 Nws |

| Cu | 0.0015 Nws |

| K | 0.008 0 |

| N | 0.003 ib |

| Sn | 0.0015 Nws |

| Si | 0.0020 Nws |

| Ca | 0.0015 Nws |

| Na | 0.0020 Nws |

| O | 0.008 ib |

| Ti | 0.0010 Nws |

| Mg | 0.0010 Nws |

| Khoom siv | Kev ntsuas kub (℃) | Phaj Thickness (mm) | Kev sim ua ntej kev kho cua sov |

| Mo | 1100 | 1.5 | 1200 ℃ / 1h |

|

| 1450 | 2.0 | 1500 ℃ / 1h |

|

| 1800 | 6.0 | 1800 ℃ / 1h |

| TZM | 1100 | 1.5 | 1200 ℃ / 1h |

|

| 1450 | 1.5 | 1500 ℃ / 1h |

|

| 1800 | 3.5 | 1800 ℃ / 1h |

| MLR | 1100 | 1.5 | 1700 ℃ / 3h |

|

| 1450 | 1.0 | 1700 ℃ / 3h |

|

| 1800 | 1.0 | 1700 ℃ / 3h |

1. Peb lub Hoobkas nyob hauv Luoyang City, Henan Province. Luoyang yog thaj chaw tsim khoom rau tungsten thiab molybdenum mines, yog li peb muaj qhov zoo ntawm qhov zoo thiab tus nqi;

2. Peb lub tuam txhab muaj cov kws tshaj lij nrog ntau tshaj 15 xyoo kev paub, thiab peb muab cov kev daws teeb meem thiab cov lus qhia rau txhua tus neeg siv khoom xav tau.

3. Tag nrho peb cov khoom raug soj ntsuam nruj ua ntej xa tawm.

4. Yog tias koj tau txais cov khoom tsis raug, koj tuaj yeem tiv tauj peb kom them rov qab.

1. Oxide

(molybdenum sesquioxide)

2. Kev txo qis

(Kev txo cov tshuaj rau txo cov hmoov molybdenum)

3. Kev sib xyaw thiab ua kom zoo ntawm cov hlau

(Ib qho ntawm peb cov peev txheej tseem ceeb)

4. Nias

(Siv thiab nias hlau hmoov)

5. Sinter

(Powder hais yog rhuab nyob rau hauv ib puag ncig tiv thaiv roj los tsim tsawg porosity sintered blocks)

6. Ua kom zoo

(Qhov ceev thiab mechanical zog ntawm cov ntaub ntawv nce nrog cov degree ntawm kev sib sau)

7. Kev kho cua sov

(Los ntawm kev kho cua sov, nws muaj peev xwm sib npaug ntawm cov neeg kho tshuab kev ntxhov siab, cuam tshuam rau cov khoom siv, thiab xyuas kom meej tias cov hlau ua tau yooj yim rau yav tom ntej)

8. Machining

(Kev tshaj lij machining cov kab ntau lawm kom paub meej tus nqi ntawm ntau yam khoom)

9. Kev ruaj ntseg zoo

(Kev txais yuav zoo, kev nyab xeeb, thiab kev tswj hwm ib puag ncig kom ntseeg tau thiab ua kom zoo dua cov khoom thiab kev pabcuam zoo)

10. Rov ua dua

(Tshuaj, thermal, thiab kho tshuab ntawm kev tsim khoom muaj feem xyuam nrog cov khoom seem thiab cov khoom siv rov siv dua tuaj yeem pab tiv thaiv cov peev txheej ntuj)

Molybdenum lub hom phiaj feem ntau yog siv hauv X-ray raj rau kev kuaj mob, tshuaj xyuas kev lag luam, thiab kev tshawb fawb tshawb fawb. Cov ntawv thov rau cov hom phiaj molybdenum yog feem ntau hauv kev tsim hluav taws xob X-rays rau kev kuaj pom, xws li suav tomography (CT) scans thiab radiography.

Molybdenum lub hom phiaj yog nyiam rau lawv qhov siab melting point, uas tso cai rau lawv tiv taus qhov kub thiab txias tsim thaum lub sij hawm X-ray ntau lawm. Lawv kuj muaj thermal conductivity zoo, pab kom dissipate tshav kub thiab ntev lub neej ntawm X-ray raj.

Ntxiv nrog rau kev kuaj pom kev kho mob, cov hom phiaj molybdenum yog siv rau kev sim tsis muaj kev puas tsuaj hauv kev lag luam, xws li tshuaj xyuas cov vuam, cov kav dej thiab cov khoom siv hauv aerospace. Lawv kuj tau siv rau hauv cov chaw tshawb fawb uas siv X-ray fluorescence (XRF) spectroscopy rau kev txheeb xyuas cov khoom siv thiab kev txheeb xyuas lub ntsiab lus.

Molybdenum feem ntau yog siv los ua cov khoom siv hauv kev mammography vim nws cov khoom muaj txiaj ntsig zoo rau kev tshuaj xyuas cov ntaub so ntswg ntawm lub mis. Molybdenum muaj tus lej atomic tsawg, uas txhais tau hais tias X-rays nws tsim yog qhov zoo tagnrho rau cov duab mos xws li lub mis. Molybdenum tsim cov yam ntxwv X-rays ntawm qis zog, ua rau lawv zoo tagnrho rau kev soj ntsuam qhov sib txawv me me hauv cov ntaub so ntswg ntawm lub mis.

Tsis tas li ntawd, molybdenum muaj cov thermal conductivity zoo, uas yog ib qho tseem ceeb hauv cov khoom siv mammography uas rov ua X-ray raug ntau. Lub peev xwm los ua kom cov cua sov kom zoo pab tswj kev ruaj ntseg thiab kev ua haujlwm ntawm X-ray raj nyob rau lub sijhawm ntev ntawm kev siv.

Zuag qhia tag nrho, kev siv cov molybdenum ua cov khoom siv hauv kev mammography pab txhim kho qhov zoo ntawm lub mis imaging los ntawm kev muab cov khoom X-ray tsim nyog rau daim ntawv thov tshwj xeeb no.

Lub hom phiaj sputter yog cov khoom siv hauv lub cev vapor deposition (PVD) txheej txheem los tsim cov yeeb yaj kiab nyias lossis txheej txheej ntawm cov substrates. Thaum lub sij hawm sputtering txheej txheem, ib tug high-zog ion beam bombards lub sputtering lub hom phiaj, ua rau atoms los yog molecules yuav ejected ntawm lub hom phiaj cov khoom. Cov tshuaj txau no ces muab tso rau hauv lub substrate los tsim ib zaj duab xis nyias nrog tib lub ntsiab lus raws li lub hom phiaj sputtering.

Sputtering lub hom phiaj yog tsim los ntawm ntau yam ntaub ntawv, nrog rau cov hlau, alloys, oxides thiab lwm yam sib txuas, nyob ntawm seb cov khoom xav tau ntawm cov yeeb yaj kiab tso. Kev xaiv ntawm sputtering lub hom phiaj cov khoom tuaj yeem cuam tshuam rau cov khoom ntawm cov yeeb yaj kiab, xws li nws cov hluav taws xob conductivity, kho qhov muag lossis cov khoom sib nqus.

Sputtering lub hom phiaj yog dav siv nyob rau hauv ntau yam lag luam xws li semiconductor manufacturing, optical txheej, thiab nyias zaj duab xis hnub ci hlwb. Sputtering lub hom phiaj 'precise control over thin film deposition ua rau lawv tseem ceeb hauv kev tsim cov khoom siv hluav taws xob thiab kho qhov muag.

Muaj ntau qhov kev txiav txim siab koom nrog hauv kev xaiv thiab siv cov hom phiaj molybdenum rau kev ua haujlwm zoo:

1. Purity thiab muaj pes tsawg leeg: High-purity molybdenum lub hom phiaj cov ntaub ntawv raug xaiv los xyuas kom meej thiab txhim khu kev qha sputtering kev ua tau zoo. Qhov sib xyaw ntawm molybdenum lub hom phiaj yuav tsum tau ua kom haum rau cov kev xav tau ntawm cov yeeb yaj kiab tshwj xeeb, xws li cov yeeb yaj kiab uas xav tau thiab cov yam ntxwv adhesion.

2. Cov qauv nplej: Ua tib zoo saib cov qauv nplej ntawm lub hom phiaj molybdenum vim nws yuav cuam tshuam rau cov txheej txheem sputtering thiab qhov zoo ntawm cov yeeb yaj kiab tso. Fine-grained molybdenum lub hom phiaj txhim kho sputtering uniformity thiab kev ua yeeb yaj kiab.

3. Lub hom phiaj geometry thiab qhov loj me: Xaiv lub hom phiaj geometry thiab qhov loj kom haum rau cov txheej txheem sputtering thiab cov txheej txheem yuav tsum tau ua. Lub hom phiaj tsim yuav tsum xyuas kom meej sputtering zoo thiab cov yeeb yaj kiab tso rau ntawm lub substrate.

4. Cua txias thiab cua sov dissipation: tsim nyog cov cua txias thiab cua sov dissipation mechanisms yuav tsum tau siv los tswj cov thermal cuam tshuam thaum lub sij hawm sputtering txheej txheem. Qhov no yog qhov tseem ceeb tshwj xeeb tshaj yog rau cov hom phiaj molybdenum, vim lawv muaj kev cuam tshuam rau cov teeb meem kub ntxhov.

5. Sputtering tsis: Optimize sputtering tsis xws li lub hwj chim, siab, thiab roj ntws mus cuag cov yam xav tau zaj duab xis thiab deposition tus nqi thaum txo lub hom phiaj yaig thiab xyuas kom meej lub hom phiaj mus sij hawm ntev kev ua tau zoo.

6. Kev tu thiab tuav: Ua raws li kev pom zoo molybdenum lub hom phiaj tuav, kev teeb tsa thiab kev saib xyuas cov txheej txheem kom ntev nws lub neej kev pab cuam thiab tswj kev ua haujlwm zoo ib yam.

Los ntawm kev xav txog cov xwm txheej no thiab ua raws li cov kev coj ua zoo tshaj plaws thaum xaiv thiab siv cov hom phiaj molybdenum, qhov kev ua tau zoo tshaj plaws ntawm sputtering tuaj yeem ua tiav, ua rau cov khoom zoo tshaj plaws nyias zaj duab xis tso rau ntau yam kev siv.