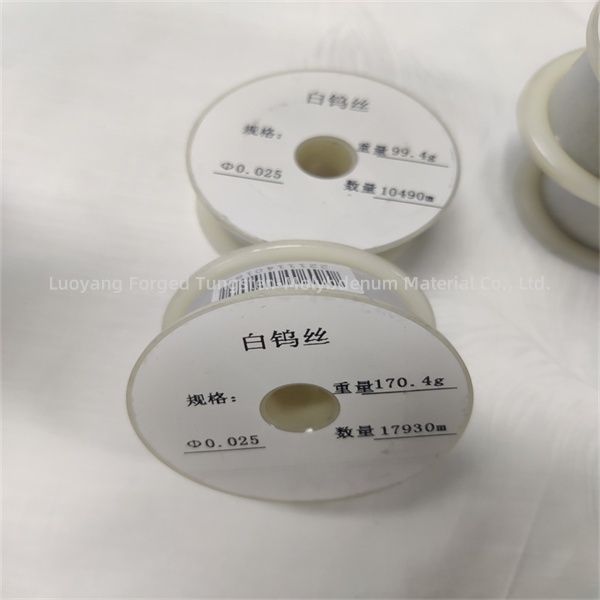

0.025mm tungsten hlau 99.95% ntshiab tungsten filament

Ntxiv nrog rau kev siv lub teeb pom kev zoo, tungsten hlau yog dav siv los ua lub teeb pom kev zoo hauv lwm cov khoom siv hluav taws xob xws li TV, cov ntxaij vab tshaus, lasers, lub tshuab nqus tsev hluav taws xob, thiab cov raj hluav taws xob. Cov tungsten hlau lub teeb-emitting Cheebtsam hauv cov khoom siv no tuaj yeem tsim qhov ci ntsa iab, zoo ruaj khov, thiab lub neej ntev lub teeb ci, ua tau raws li ntau yam kev xav tau.

| Txoj kab uas hla | Customizable |

| Qhov Chaw Keeb Kwm | Henan, Luoyang |

| Hom Lub Npe | FGD |

| Daim ntawv thov | Kev kho mob, cua sov caij, kev lag luam |

| Cov duab | Ncaj |

| Nto | Polished |

| Purity | 99.95% Min |

| Khoom siv | Ntshiab W |

| Qhov ntom | 19.3g / cm3 |

| MOQ | 1kg ua |

| Txoj kab uas hla ntawm cov khoom siv lo lo ntxhuavd,m ib | Qhov hnyav ntawm 200mm silk ntu, mg | Yam tsawg kawg nkaus, m |

| 5≤d≤10 | 0.075-0.30 Nws | 300 |

| 10≤d≤60 | >0.30-10.91 Nws | 400 |

| 60<d≤100 | >10.91-30.30 Nws | 350 |

| 100<d≤150 | >30.30–68.18 dr hab | 200 |

| 150<d≤200 | >68.18-121.20 Nws | 100 |

| 200<d≤350 | >121.20 ~ 371.19 ib | 50 |

| 350<d≤700 | / | Sib npaug rau qhov ntev ntawm 75g hauv qhov hnyav |

| 700<d≤1800 | / | Sib npaug rau qhov ntev ntawm 75g hauv qhov hnyav |

| Txoj kab uas hla ntawm silk ld, μm | Qhov hnyav ntawm 200mm silk ntu, mg | Qhov hnyav ntawm 200mm silk ntu sib txawv | Txoj kab uas hla sib txawv % | |||

| 0 qib | kuv qib | II qib | kuv qib | II qib | ||

| 5≤d≤10 | 0.075-0.30 Nws | / | ± 4 | ± 5 | / | / |

| 10≤d≤18 | 0.30-0.98 Nws | / | ± 3 | ± 4 | / | / |

| 18≤d≤40 | 0.98-4.85 Nws | ± 2 | ± 2.5 | ± 3 | / | / |

| 40 d <80 | 4.85–19.39 dr hab | ± 1.5 | ± 2.0 | ± 2.5 | / | / |

| 80<d≤300 | 19.39–272.71 | ± 1.0 | ± 1.5 | ± 2.0 | / | / |

| 300<d≤350 | 272.71–371.19 | / | ± 1.0 | ± 1.5 | / | / |

| 350<d≤500 | / | / | / | / | ± 1.5 | ± 2.0 |

| 500<d≤1800 | / | / | / | / | ± 1.0 | ± 1.5 |

1. Peb lub Hoobkas nyob hauv Luoyang City, Henan Province. Luoyang yog thaj chaw tsim khoom rau tungsten thiab molybdenum mines, yog li peb muaj qhov zoo ntawm qhov zoo thiab tus nqi;

2. Peb lub tuam txhab muaj cov kws tshaj lij nrog ntau tshaj 15 xyoo kev paub, thiab peb muab cov kev daws teeb meem thiab cov lus qhia rau txhua tus neeg siv khoom xav tau.

3. Tag nrho peb cov khoom raug soj ntsuam nruj ua ntej xa tawm.

4. Yog tias koj tau txais cov khoom tsis raug, koj tuaj yeem tiv tauj peb kom them rov qab.

1.Extraction ntawm raw khoom

2. tshuaj kho mob

3. Txo cov tungsten hmoov

4.Nias thiab sintering

5. Kev kos duab

6.Nyob zoo

7. Kev kho deg

8. Kev Tswj Xyuas Zoo

9. Ntim

1. Cov khoom siv hluav taws xob thiab cov khoom siv lub tshuab nqus tsev: tungsten hlau yog siv los ua cov khoom siv hluav taws xob thiab cov cua sov rau cov phom hluav taws xob kub hauv cov ntawv thov. Lawv kuj tau siv ntau hauv cov khoom siv nqus tsev xws li cov raj kub electron, electron microscopes, thiab cov khoom siv roj ionization.

2. Lub teeb pom kev zoo: Vim nws muaj peev xwm ua kom pom lub teeb ci ntawm qhov kub thiab txias thiab nws tsis kam ua kom tawg, tungsten hlau yog dav siv los ua lub teeb pom kev zoo hauv cov khoom siv hluav taws xob.

3. Resistance heater: Lub siab melting point thiab kub tsis kam ntawm tungsten hlau ua rau nws yog ib qho khoom siv zoo rau cov cua sov. Lawv feem ntau siv rau hauv tsev thiab cov khoom siv hluav taws xob cua sov xws li lub qhov cub hluav taws xob, qhov cub, thiab cov hlau.

4. Vuam thiab txiav: tungsten hlau feem ntau yog siv los ua cov khoom siv hluav taws xob hauv kev siv hluav taws xob siab thiab txiav cov txheej txheem xws li argon arc vuam, laser txiav, thiab electron beam vuam. Nws qhov siab melting point thiab corrosion kuj ua rau nws yog ib qho kev xaiv zoo tshaj plaws rau kev pib arc thiab tso tawm tam sim no hauv cov txheej txheem no.

5. Chemical reactors: Hauv qee cov tshuaj reactors, tungsten xov hlau yog siv los ua catalysts thiab txhawb cov ntaub ntawv los txhim kho cov tshuaj tiv thaiv thiab kev ruaj ntseg.

Ntxiv rau cov ntawv thov saum toj no, tungsten hlau kuj tau siv dav hauv kev lag luam textile, aerospace, kev lag luam nuclear, thiab kev kho mob.