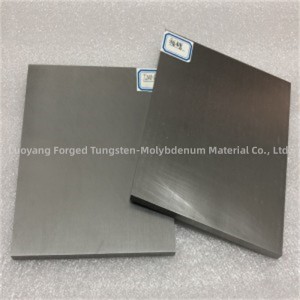

Customized Mo La Alloy Phaj Rau Cov Hluav Taws Xob Hluav Taws Xob

Kev tsim cov nplooj ntawv molybdenum-lanthanum (Mo-La) feem ntau suav nrog cov txheej txheem tsim khoom. Cov txheej txheem no yuav suav nrog: Kev npaj cov khoom nyoos:

Thawj kauj ruam yuav tsum tau txais cov khoom tsim nyog, xws li molybdenum thiab lanthanum, nyob rau hauv daim ntawv ntawm cov hmoov los yog lwm yam khoom siv raw. Cov ntaub ntawv nyoos no raug xaiv raws li lawv cov purity thiab xav tau alloy muaj pes tsawg leeg. Blending thiab Mixing: Molybdenum thiab lanthanum hmoov yog tov ua ke nyob rau hauv meej proportions kom tau raws li qhov xav tau alloy muaj pes tsawg leeg. Qhov sib tov yog tov kom huv si kom paub meej tias txawm faib cov khoom xyaw. Compaction: Cov hmoov sib xyaw ua ke yog ces compacted nyob rau hauv siab siab los tsim ib tug ntom thiab coherent ntsuab lub cev. Compaction tuaj yeem ua tiav siv cov txheej txheem xws li txias isostatic nias (CIP) lossis uniaxial nias. Sintering: Lub cev ntsuab yog sintered nyob rau hauv lub qhov cub kub kub nyob rau hauv ib qho chaw tswj kom ua tiav cov khoom sib txawv ntawm lub xeev kev sib txuas ntawm molybdenum thiab lanthanum hais. Cov txheej txheem no ua rau muaj kev tsim cov tuab thiab tag nrho cov khoom noj mo-la-alloy. Kub dov: Cov khoom siv sintered Mo-La alloy yog tom qab ntawd raug rau cov txheej txheem kub dov kom tau txais cov thickness thiab cov khoom siv kho tshuab. Cov txheej txheem kub dov yuav dhau los ntawm cov khoom siv los ntawm ntau cov yob ntawm qhov kub thiab txias kom txo nws cov thickness thiab txhim kho nws cov microstructure. Annealing: Tom qab kub dov, Mo-La alloy phaj yuav dhau los ua cov txheej txheem annealing kom tshem tawm cov kev ntxhov siab sab hauv thiab ntxiv kho nws cov microstructure. Annealing feem ntau yog ua ntawm qhov kub thiab txias rau lub sijhawm tswj. Kev Kho Hniav thiab Ua tiav: Mo-La alloy daim hlau tuaj yeem ua rau kev kho deg ntxiv xws li pickling, machining lossis polishing kom ua tiav qhov yuav tsum tau ua tiav thiab qhov ntev ntev. Kev Tswjhwm Zoo thiab Kev Ntsuas: Thoob plaws hauv cov txheej txheem tsim khoom, Mo-La alloy nplooj ntawv tau txais kev tswj xyuas nruj thiab kev sim kom ntseeg tau tias lawv cov khoom siv kho tshuab, microstructure thiab tshuaj lom neeg muaj pes tsawg leeg ua tau raws li qhov yuav tsum tau ua.

Cov txheej txheem ntau lawm saum toj no yog cov ntsiab lus dav dav thiab tuaj yeem sib txawv nyob ntawm cov txheej txheem tsim khoom tshwj xeeb thiab cov cuab yeej siv los ntawm cov tuam txhab sib txawv. Cov kauj ruam meej thiab tsis muaj kev koom tes hauv kev tsim cov nplooj ntawv Mo-La alloy yuav nyob ntawm cov yam xws li cov ntawv xav tau, cov khoom siv kho tshuab thiab kev siv kawg.

Molybdenum-lanthanum (Mo-La) alloy nplooj ntawv yog siv nyob rau hauv ntau yam kev siv vim lawv cov khoom tshwj xeeb. Mo-La alloy daim hlau paub txog lawv qhov kub thiab txias zog, zoo thermal conductivity, thermal shock kuj thiab zoo heev machinability. Cov khoom no ua rau Mo-La alloy phaj haum rau qhov kub thiab txias ib puag ncig thiab xav tau daim ntawv thov xws li:

Rauv Cheebtsam: Mo-La alloy nplooj ntawv yog siv nyob rau hauv kev tsim kho ntawm industrial furnaces thiab cov khoom siv kho cua sov vim lawv muaj peev xwm tiv taus kub thiab thermal cycling. Aerospace kev lag luam: Mo-La alloy daim hlau yog siv nyob rau hauv aerospace Cheebtsam, xws li foob pob ua ntxaij nozzles, combustion chambers thiab lwm yam high-temperature structural Cheebtsam. Kev lag luam iav: Mo-La alloy nplooj ntawv yog siv rau hauv cov txheej txheem iav, tshwj xeeb tshaj yog nyob rau hauv kev tsim cov iav pwm, stirrers thiab tank reinforcements vim lawv tsis kam rau molten iav thiab thermal shock. Radiators thiab Heat Exchangers: Mo-La alloy daim hlau yog siv rau hauv kev tswj xyuas thermal xws li cov dab dej kub rau cov khoom siv hluav taws xob thiab cov khoom siv hluav taws xob rau cov txheej txheem kub. Sputtering lub hom phiaj: Mo-La alloy phaj yog siv los ua lub hom phiaj sputtering rau nyias zaj duab xis deposition hauv semiconductor thiab electronics manufacturing. Hluav taws xob tiv tauj: Mo-La alloy daim hlau yog siv rau hauv kev sib cuag hluav taws xob thiab cov hluav taws xob hluav taws xob vim lawv cov hluav taws xob zoo thiab ua haujlwm rau arc yaig. Kev Kho Mob thiab Nuclear Daim Ntawv Thov: Mo-La alloy nplooj ntawv yog siv rau hauv kev tiv thaiv hluav taws xob thiab cov khoom siv kub kub hauv kev kho mob thiab kev lag luam nuclear.

Zuag qhia tag nrho, Mo-La alloy nplooj ntawv muaj nuj nqis rau lawv qhov sib xyaw ua ke ntawm qhov kub thiab txias, thermal conductivity, thiab tsis kam mus rau qhov chaw hnyav, ua rau lawv tseem ceeb hauv ntau yam kev lag luam.

Wechat: 15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com