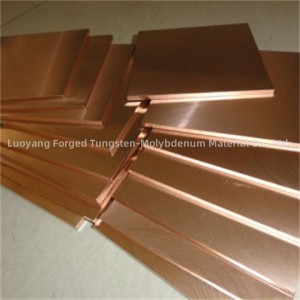

High Quality Molybdenum Copper Alloy phaj

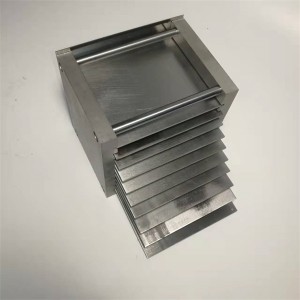

Molybdenum-tooj liab hlau phaj feem ntau yog tsim los ntawm cov txheej txheem hmoov metallurgy. Qhov no suav nrog kev sib tov zoo molybdenum hmoov thiab tooj liab hmoov ua ke los ua ib qho kev sib xyaw ua ke. Cov hmoov yog ces compacted nyob rau hauv siab siab nyob rau hauv ib tug pwm los ua ib tug ntsuab lub cev. Lub cev ntsuab no ces sintered ntawm qhov kub thiab txias nyob rau hauv ib qho chaw tswj kom khi cov molybdenum thiab tooj liab hais los ua ib tug ntom thiab muaj zog alloy phaj. Tom qab sintering, molybdenum-tooj liab alloy nplooj ntawv tuaj yeem dhau los ua cov txheej txheem ntxiv xws li kub dov, txias dov lossis kho cua sov kom tau txais qhov yuav tsum tau muaj qhov ntev, cov khoom siv kho tshuab thiab qhov chaw tiav. Cov khoom kawg yog kuaj xyuas zoo thiab tom qab ntawd npaj rau kev faib tawm thiab siv ntau yam kev siv. Nws yog ib qho tseem ceeb uas yuav tsum nco ntsoov tias cov kev tsim khoom tshwj xeeb yuav txawv nyob ntawm cov chaw tsim khoom thiab cov khoom xav tau ntawm molybdenum tooj liab alloy phaj.

Yog tias koj xav tau cov ntsiab lus ntxiv txog ib txoj kev tsim khoom tshwj xeeb lossis muaj lwm cov lus nug ntsig txog lub ncauj lus no, thov koj xav nug!

Cov nplooj ntawv molybdenum-tooj liab feem ntau yog siv rau hauv kev siv hluav taws xob thiab hluav taws xob vim lawv cov thermal conductivity zoo, hluav taws xob conductivity thiab kub tsis kam. Cov nplooj ntawv no feem ntau siv rau hauv kev tsim cov dab dej kub, hluav taws xob hluav taws xob substrates, thiab lub zog hluav taws xob microwave thiab xov tooj cua zaus (RF). Lub siab thermal conductivity ntawm molybdenum-tooj liab alloy daim hlau ua rau lawv zoo tagnrho rau cov kev siv uas muaj cua sov dissipation tseem ceeb heev. Tsis tas li ntawd, lawv cov khoom siv hluav taws xob zoo tuaj yeem xa cov hluav taws xob thiab cov khoom siv hluav taws xob zoo, ua rau lawv tsim nyog rau kev sib xyaw ua ke, hluav taws xob semiconductors thiab lwm yam khoom siv hluav taws xob. Cov nplooj ntawv molybdenum-tooj liab kuj tseem siv rau hauv kev lag luam aerospace thiab kev tiv thaiv vim lawv muaj peev xwm tiv taus qhov kub thiab txias. Lawv kev sib xyaw ua ke ntawm cov thermal conductivity thiab lub zog ua rau lawv tsim nyog rau kev siv nyob rau hauv tshav kub exchangers, foob pob ua ntxaij nozzles thiab lwm yam kev siv uas yuav tsum tau cov ntaub ntawv los tiv thaiv huab cua.

Zuag qhia tag nrho, molybdenum-tooj liab alloy daim hlau muaj nuj nqis rau lawv kev sib xyaw ua ke ntawm thermal thiab hluav taws xob, uas ua rau lawv zoo haum rau ntau yam kev thov hauv ntau qhov kev lag luam.

| Khoom npe | Molybdenum Copper Alloy Phaj |

| Khoom siv | Mo1 |

| Specification | Customized |

| Nto | Cov tawv nqaij dub, alkali ntxuav, polished. |

| Cov txheej txheem | Sintering txheej txheem, machining |

| Meltng point | 2600 ℃ |

| Qhov ntom | 10.2g / cm3 |

Wechat: 15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com