Kiʻekiʻe wela poʻi molybdenum pōʻai molybdenum pahu hopu no ka ʻoihana noi

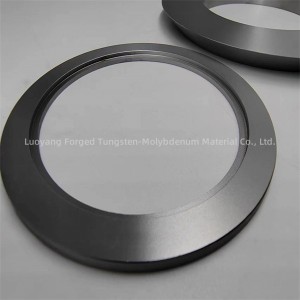

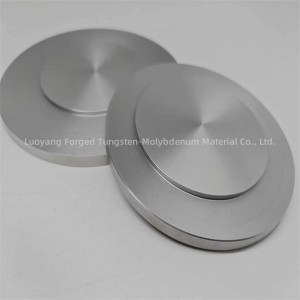

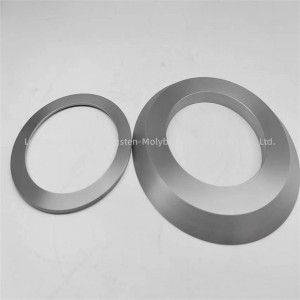

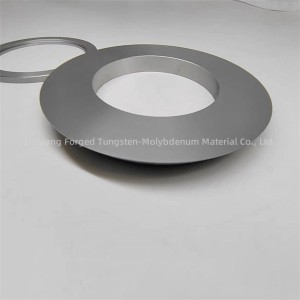

ʻO ka molybdenum target material kahi mea ʻenehana i hoʻohana nui ʻia i nā kula kiʻekiʻe e like me ka hana semiconductor, ʻenehana deposition kiʻi ʻoniʻoni ʻoniʻoni, ʻoihana photovoltaic, a me nā mea hana imaging. Hana ʻia ia me ka molybdenum maʻemaʻe kiʻekiʻe, me ka helu heheʻe kiʻekiʻe, maikaʻi ka uila a me ka thermal conductivity, e hiki ai i nā pahuhopu molybdenum ke noho paʻa i ka wela kiʻekiʻe a i ʻole nā pilikia kiʻekiʻe. ʻO ka maʻemaʻe o nā mea i hoʻopaʻa ʻia molybdenum maʻamau he 99.9% a i ʻole 99.99%, a ʻo nā kikoʻī e pili ana i nā pahuhopu pōʻai, nā pahu pā, a me nā pahu huli.

| Anana | E like me kāu koi |

| Kahi i kumu | Henan, Luoyang |

| Kapa inoa | FGD |

| Palapala noi | Lapaʻau, ʻOihana, semiconductor |

| Kinohi | Poʻapuni |

| Ili | Hoʻomaʻamaʻa ʻia |

| Maemae | 99.95% Min |

| Mea waiwai | Maemae Mo |

| ʻO ka mānoanoa | 10.2g/cm3 |

| Nā mea nui | Mo>99.95% |

| maʻiʻo haumia≤ | |

| Pb | 0.0005 |

| Fe | 0.0020 |

| S | 0.0050 |

| P | 0.0005 |

| C | 0.01 |

| Cr | 0.0010 |

| Al | 0.0015 |

| Cu | 0.0015 |

| K | 0.0080 |

| N | 0.003 |

| Sn | 0.0015 |

| Si | 0.0020 |

| Ca | 0.0015 |

| Na | 0.0020 |

| O | 0.008 |

| Ti | 0.0010 |

| Mg | 0.0010 |

| Mea waiwai | Ka Mahana Hoao (℃) | Mānoanoa Papa (mm) | Hoʻomaʻamaʻa wela ma mua o ka hoʻokolohua |

| Mo | 1100 | 1.5 | 1200℃/1h |

|

| 1450 | 2.0 | 1500℃/1h |

|

| 1800 | 6.0 | 1800℃/1h |

| TZM | 1100 | 1.5 | 1200℃/1h |

|

| 1450 | 1.5 | 1500℃/1h |

|

| 1800 | 3.5 | 1800℃/1h |

| MLR | 1100 | 1.5 | 1700℃/3h |

|

| 1450 | 1.0 | 1700℃/3h |

|

| 1800 | 1.0 | 1700℃/3h |

1. Aia kā mākou hale hana ma Luoyang City, Henan Province. He wahi hana ʻo Luoyang no nā mines tungsten a me molybdenum, no laila, loaʻa iā mākou nā mea maikaʻi loa i ka maikaʻi a me ke kumukūʻai;

2. Loaʻa i kā mākou hui nā limahana loea me ka ʻoi aku o 15 mau makahiki o ka ʻike, a hāʻawi mākou i nā hoʻonā a me nā manaʻo no kēlā me kēia mea kūʻai aku.

3. ʻO kā mākou huahana a pau e nānā pono i ka maikaʻi ma mua o ka lawe ʻia ʻana aku.

4. Inā loaʻa iāʻoe nā waiwai hemahema, hiki iāʻoe ke hoʻokaʻaʻike mai iā mākou no ka uku.

1. Oxide

(molybdenum sesquioxide)

2. Hoemi

(Ke ʻano hoʻemi kemika no ka hōʻemi ʻana i ka pauka molybdenum)

3. ʻO ka huiʻana a me ka hoʻomaʻemaʻeʻana i nā'āpana

(Kekahi o kā mākou mau mākau kumu)

4. Kaomi ana

(Ka hui ʻana a me ke kaomi ʻana i ka pauka metala)

5. Sinter

(Hoʻomaʻamaʻa ʻia nā ʻāpana pauka i loko o kahi kaiapuni pale e hana i nā poloka sintered porosity haʻahaʻa)

6. Lawe i ke kino

(Hoʻonui ka nui a me ka ikaika mechanical o nā mea me ke ʻano o ka hana ʻana)

7. Hana wela

(Ma o ka hoʻomaʻamaʻa wela, hiki ke kaulike i ke koʻikoʻi mechanical, pili i nā waiwai waiwai, a e hōʻoia i ka maʻalahi o ka metala i ka wā e hiki mai ana)

8. Mīkini

(Hōʻike ka laina hana machining ʻoihana i ka helu kūpono o nā huahana like ʻole)

9. Hōʻoia maikaʻi

(Hoʻohana i nā ʻōnaehana hoʻokele maikaʻi, palekana, a me ka hoʻokele kaiapuni e hōʻoia a hoʻomau mau i ka maikaʻi o ka huahana a me ka lawelawe)

10. Hana hou

(Hiki ke kōkua i ka mālama ʻana i nā kumuwaiwai kūlohelohe i ka hoʻomaʻamaʻa ʻana i ke kemika, ka wela, a me ka mīkini i nā mea keu e pili ana i ka hana a me nā huahana ʻōpala i hana hou ʻia)

Hoʻohana maʻamau ʻia nā pahuhopu Molybdenum i nā paipu X-ray no ke kiʻi lāʻau lapaʻau, ka nānā ʻana i nā ʻoihana, a me ka noiʻi ʻepekema. ʻO nā noi no nā pahuhopu molybdenum ka mea nui i ka hoʻomohala ʻana i nā kukui X-hiki no ke kiʻi diagnostic, e like me ka computed tomography (CT) scans a me ka radiography.

Hoʻohana ʻia nā pahuhopu Molybdenum no ko lākou wahi hoʻoheheʻe kiʻekiʻe, e hiki ai iā lākou ke pale i nā wela kiʻekiʻe i hana ʻia i ka wā hana X-ray. Loaʻa iā lākou ka conductivity thermal maikaʻi, kōkua i ka hoʻopau ʻana i ka wela a hoʻolōʻihi i ke ola o ka paipu X-ray.

Ma waho aʻe o ke kiʻi lāʻau lapaʻau, hoʻohana ʻia nā pahuhopu molybdenum no ka hoʻāʻo ʻole luku ʻana i nā noi ʻoihana, e like me ka nānā ʻana i nā welds, nā paipu a me nā ʻāpana aerospace. Hoʻohana ʻia lākou i nā keʻena noiʻi e hoʻohana ana i ka spectroscopy X-ray fluorescence (XRF) no ka nānā ʻana i nā mea a me ka ʻike elemental.

Hoʻohana pinepine ʻia ʻo Molybdenum ma ke ʻano he mea paʻa i ka mammography ma muli o kāna mau waiwai maikaʻi no ke kiʻi ʻana i ka ʻiʻo umauma. He helu atomic haʻahaʻa ka Molybdenum, ʻo ia hoʻi, ʻo nā hihi X i hana ʻia he mea kūpono ia no ke kiʻi ʻana i nā mea palupalu e like me ka umauma. Hoʻopuka ʻo Molybdenum i nā kukui X maʻamau i nā pae ikehu haʻahaʻa, e hoʻolilo iā lākou i mea kūpono no ka nānā ʻana i nā ʻokoʻa liʻiliʻi o ka nui o ka umauma.

Eia kekahi, loaʻa i ka molybdenum nā waiwai conductivity thermal maikaʻi, he mea nui ia i nā mea hana mammography kahi i maʻa mau ai nā hōʻike X-ray. ʻO ka hiki ke hoʻopau maikaʻi i ka wela e kōkua i ka mālama ʻana i ke kūpaʻa a me ka hana o nā paipu X-ray i nā manawa lōʻihi o ka hoʻohana.

Ma ke ʻano holoʻokoʻa, ʻo ka hoʻohana ʻana i ka molybdenum ma ke ʻano he mea i hoʻopaʻa ʻia i ka mammography e kōkua i ka maikaʻi o ke kiʻi umauma ma o ka hāʻawi ʻana i nā waiwai X-ray kūpono no kēia noi kikoʻī.

ʻO ka pahuhopu sputter kahi mea i hoʻohana ʻia i ke kaʻina hana mahu kino (PVD) e hana i nā kiʻiʻoniʻoni ʻoniʻoni a i ʻole nā pale ma nā substrate. I ke kaʻina hana sputtering, hoʻokuʻu ʻia nā ʻātoma a i ʻole nā molekala mai ka mea i hoʻopaʻa ʻia. Hoʻokomo ʻia kēia mau ʻāpana i hoʻoheheʻe ʻia ma luna o ka substrate e hana i kahi kiʻiʻoniʻoni ʻoniʻoni me ke ʻano like me ka pahuhopu sputtering.

Hana ʻia nā pahuhopu sputtering mai nā ʻano mea like ʻole, me nā metala, nā mea hoʻohui, nā oxides a me nā mea hoʻohui ʻē aʻe, e pili ana i nā waiwai i makemake ʻia o ke kiʻiʻoniʻoni i waiho ʻia. Hiki i ke koho o ka sputtering target mea hiki ke hoʻopili nui i nā waiwai o ka hopena kiʻiʻoniʻoni, e like me kona conductivity uila, nā waiwai optical a i ʻole nā mea magnetic.

Hoʻohana nui ʻia nā pahuhopu sputtering i nā ʻoihana like ʻole e like me ka semiconductor manufacturing, optical coating, a me nā kiʻi ʻoniʻoni ʻoniʻoni solar. ʻO ka mana pololei o ka sputtering targets ma luna o ka waiho ʻia ʻana o nā kiʻiʻoniʻoni lahilahi, he mea koʻikoʻi lākou i ka hana ʻana i nā mea uila a me ka optical.

Nui nā manaʻo e pili ana i ke koho ʻana a me ka hoʻohana ʻana i nā pahuhopu molybdenum no ka hana maikaʻi loa:

1. Maʻemaʻe a me ka haku mele ʻana: Ua koho ʻia nā mea pahuhopu molybdenum maʻemaʻe kiʻekiʻe e hōʻoia i ka hana sputtering kūpaʻa a hilinaʻi. Pono e hoʻopili ʻia ke ʻano o ka pahu molybdenum i nā koi deposition kiʻiʻoniʻoni kūikawā, e like me nā waiwai kiʻiʻoniʻoni i makemake ʻia a me nā ʻano adhesion.

2. Hoʻolālā palaoa: E noʻonoʻo i ke ʻano o ka palaoa o ka pahu molybdenum e pili ana i ke kaʻina sputtering a me ka maikaʻi o ke kiʻi i waiho ʻia. ʻO nā pahuhopu molybdenum maikaʻi e hoʻomaikaʻi i ka like ʻana o ka sputtering a me ka hana kiʻiʻoniʻoni.

3. Geometry a me ka nui: E koho i ka geometry a me ka nui kūpono e kūpono i ka ʻōnaehana sputtering a me nā koi kaʻina. Pono ka hoʻolālā pahuhopu e hōʻoia i ka maikaʻi o ka sputtering a me ka waiho ʻana o ke kiʻiʻoniʻoni ma luna o ka substrate.

4. ʻO ka hoʻoluʻu a me ka hoʻopau wela: Pono e hoʻohana ʻia nā mīkini hoʻomaha a me ka wela e mālama ai i nā hopena wela i ka wā o ka sputtering. He mea koʻikoʻi kēia no nā pahuhopu molybdenum, no ka mea hiki ke loaʻa nā pilikia pili i ka wela.

5. Nā ʻāpana sputtering: E hoʻonui i nā ʻāpana sputtering e like me ka mana, kaomi, a me ke kahe ʻana o ke kinoea e hoʻokō i nā waiwai kiʻiʻoniʻoni i makemake ʻia a me nā helu deposition me ka hōʻemi ʻana i ka erosion target a me ka hōʻoia ʻana i ka hana pahuhopu lōʻihi.

6. Ka mālama ʻana a me ka mālama ʻana: E hahai i ka molybdenum i ʻōlelo ʻia no ka mālama ʻana i ka pahuhopu, hoʻonohonoho a me nā kaʻina hana e hoʻonui i kona ola lawelawe a mālama i ka hana sputtering mau.

Ma ka noʻonoʻo ʻana i kēia mau mea a me ka hoʻokō ʻana i nā hana maikaʻi loa i ke koho ʻana a me ka hoʻohana ʻana i nā pahuhopu molybdenum, hiki ke hoʻokō ʻia ka hana sputtering maikaʻi loa, e hopena i ka hoʻomoe kiʻiʻoniʻoni lahilahi kiʻekiʻe no nā ʻano noi.