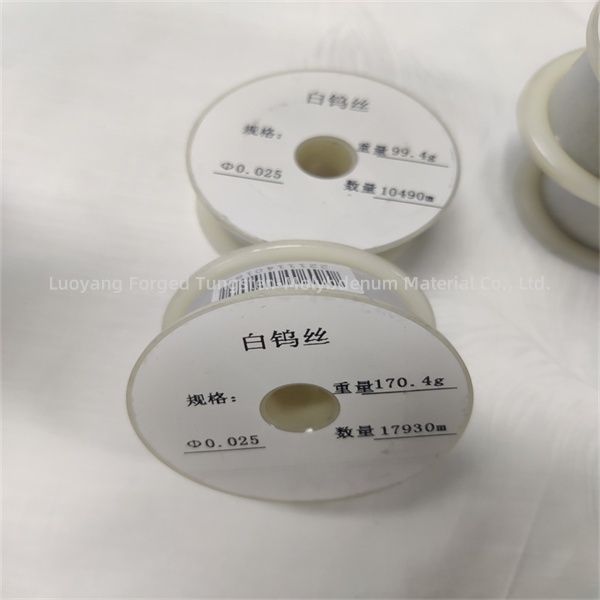

0.025mm tungsten uea 99.95% maemae tungsten filament

Ma waho aʻe o ka hoʻohana ʻana i nā ʻōpuʻu kukui, ua hoʻohana nui ʻia ka uea tungsten ma ke ʻano he mea hoʻomālamalama i nā mea uila ʻē aʻe e like me ke kīwī, nā pale hōʻike, nā lasers, nā mea uila uila, a me nā paipu uila. ʻO nā ʻāpana uila uila tungsten i kēia mau mea hiki ke hana i ka ʻōlinolino kiʻekiʻe, kūpaʻa maikaʻi, a me nā kumu kukui ola lōʻihi, e hālāwai me nā pono noi.

| Anawaena | Hoʻopilikino |

| Kahi i kumu | Henan, Luoyang |

| Kapa inoa | FGD |

| Palapala noi | Lapaʻau, Mea hoʻomehana, ʻOihana |

| Kinohi | Pololei |

| Ili | Hoʻomaʻamaʻa ʻia |

| Maemae | 99.95% Min |

| Mea waiwai | Maʻemaʻe W |

| ʻO ka mānoanoa | 19.3g/cm3 |

| MOQ | 1 kg |

| ʻO ke anawaena o ka mea silikad, μm | Ke kaumaha o 200mm mahele silika, mg | lōʻihi liʻiliʻi, m |

| 5≤d≤10 | 0.075~0.30 | 300 |

| 10≤d≤60 | >0.30~10.91 | 400 |

| 60<d≤100 | >10.91~30.30 | 350 |

| 100<d≤150 | >30.30~68.18 | 200 |

| 150<d≤200 | >68.18~121.20 | 100 |

| 200<d≤350 | >121.20~371.19 | 50 |

| 350<d≤700 | / | E like me ka lōʻihi o 75g i ke kaumaha |

| 700<d≤1800 | / | E like me ka lōʻihi o 75g i ke kaumaha |

| ʻO ke anawaena o ka siliki ld, μm | Ke kaumaha o 200mm mahele silika, mg | Kaumaha o 200mm silk māhele deviation | Weheʻe anawaena % | |||

| 0 pae | I pae | II pae | I pae | II pae | ||

| 5≤d≤10 | 0.075~0.30 | / | ±4 | ±5 | / | / |

| 10≤d≤18 | >0.30~0.98 | / | ±3 | ±4 | / | / |

| 18≤d≤40 | >0.98~4.85 | ±2 | ±2.5 | ±3 | / | / |

| 40<d≤80 | >4.85~19.39 | ±1.5 | ±2.0 | ±2.5 | / | / |

| 80<d≤300 | >19.39~272.71 | ±1.0 | ±1.5 | ±2.0 | / | / |

| 300<d≤350 | >272.71~371.19 | / | ±1.0 | ±1.5 | / | / |

| 350<d≤500 | / | / | / | / | ±1.5 | ±2.0 |

| 500<d≤1800 | / | / | / | / | ±1.0 | ±1.5 |

1. Aia kā mākou hale hana ma Luoyang City, Henan Province. He wahi hana ʻo Luoyang no nā mines tungsten a me molybdenum, no laila, loaʻa iā mākou nā mea maikaʻi loa i ka maikaʻi a me ke kumukūʻai;

2. Loaʻa i kā mākou hui nā limahana loea me ka ʻoi aku o 15 mau makahiki o ka ʻike, a hāʻawi mākou i nā hoʻonā a me nā manaʻo no kēlā me kēia mea kūʻai aku.

3. ʻO kā mākou huahana a pau e nānā pono i ka maikaʻi ma mua o ka lawe ʻia ʻana aku.

4. Inā loaʻa iāʻoe nā waiwai hemahema, hiki iāʻoe ke hoʻokaʻaʻike mai iā mākou no ka uku.

1.Extraction o nā mea maka

2. lāʻau kemika

3. Hoemi i ka pauka tungsten

4. Ke kaomi a me ka sintering

5. Kii

6.Annealing

7. Lapaʻau ʻili

8. Mana Mana

9. Hoʻopili

1. Nā mea uila a me nā mea hoʻoheheʻe: Hoʻohana ʻia ka uea Tungsten ma ke ʻano he electron emitter a me ka mea hoʻomehana no nā pu electron wela ma ia mau noi. Hoʻohana maʻamau ʻia lākou i loko o nā mea hoʻoheheʻe e like me nā paipu electron wela, nā microscopes electron, a me nā mea hana ionization gas.

2. Mālamalama kukui: Ma muli o kona hiki ke hoʻokuʻu i ke kukui'ālohilohi i nā wela kiʻekiʻe a me kona kū'ēʻana i ka hakiʻana, hoʻohana nuiʻia ke kaula tungsten ma keʻano he kumu kukui i nā'ōpuʻu incandescent kuʻuna.

3. ʻO ka mea hoʻoheheʻe kū'ē: ʻO ke kiʻekiʻe heheʻe a me ke kiʻekiʻe kiʻekiʻe o ka wela o ka uea tungsten e lilo ia i mea kūpono no nā mea hoʻomehana kū'ē. Hoʻohana pinepine ʻia lākou i loko o ka hale a me nā ʻoihana hoʻomehana uila e like me nā umu uila, umu, a me nā hao.

4. Hoʻopili a ʻokiʻoki: Hoʻohana maʻamau ʻia ka uea Tungsten e like me nā mea electrode i ka hoʻoheheʻe ʻana i ka ikehu kiʻekiʻe a me nā kaʻina hana e like me ka argon arc welding, laser cutting, a me electron beam welding. ʻO kona wahi hoʻoheheʻe kiʻekiʻe a me ka pale ʻana i ka corrosion e lilo ia i mea koho maikaʻi loa no ka hoʻomaka ʻana arc a me ka hoʻokuʻu ʻana i kēia manawa i kēia mau kaʻina.

5. Nā mea hoʻoheheʻe kemika: Ma kekahi mau mea hoʻoheheʻe kemika, ua hoʻohana ʻia nā uea tungsten ma ke ʻano he catalysts a me nā mea kākoʻo e hoʻomaikaʻi ai i ka maikaʻi o ka hopena a me ke kūpaʻa.

Ma kahi o nā noi i luna, ua hoʻohana nui ʻia ke kelepona tungsten i ka ʻoihana textile, aerospace, ʻoihana nuklea, a me nā kula olakino.

Pono e hoʻoholo ʻia ke anawaena o ka uea tungsten e like me ke ʻano o ka noi kikoʻī. ʻO ka ʻōlelo maʻamau, ʻoi aku ka maikaʻi o ke anawaena, ʻoi aku ka liʻiliʻi o ka lole a me ka haehae ʻana i ka uea tungsten, akā e emi ana ka hiki ke amo a me ke ola lawelawe. No laila, pono e koho e like me nā pono kiko'ī.

He hopena koʻikoʻi ka mea o ka uea tungsten i kāna noi. ʻOi aku ka ikaika o ka wela kiʻekiʻe a me ka pale corrosion ma mua o ka tungsten alloy. No laila, i nā kūlana e koi ʻia ai ka hoʻomaʻemaʻe kiʻekiʻe a me ke kūpaʻa corrosion kiʻekiʻe, pono e koho i ka uea tungsten maʻemaʻe; ʻOi aku ka ikaika a me ka ductility o Tungsten alloy, e kūpono ana ia no kekahi mau noi kūikawā e like me ka mīkini uila, nā lako uila uila, a me nā ʻano ʻē aʻe.

ʻO ka manawa hoʻoheheʻe o ka uea tungsten i hoʻomehana ʻia i loko o ka vacuum e pili ana i ka helu evaporation o tungsten. A ʻo ka hoʻomehana ʻana o ka uea tungsten i ka ea e hana i ka tungsten oxide. ʻO ka helu heheʻe o ka tungsten he 3410 degere. ʻO ka helu heheʻe o ka tungsten oxide, WO3, he 1400-1600 degere. Ma lalo o nā kūlana hana maʻamau, ʻo ka mahana o ka filament ma kahi o 2500 degere, a ʻo WO3 wikiwiki e vaporizes i kēia mahana, e hoʻoheheʻe koke ai ka filament i ka lewa.