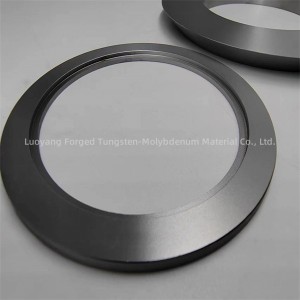

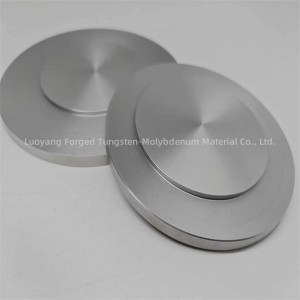

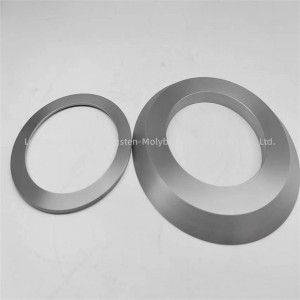

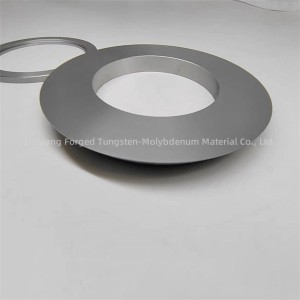

Babban zafin jiki goge molybdenum da'irar molybdenum manufa don aikace-aikacen masana'antu

Molybdenum kayan niyya abu ne na masana'antu da aka fi amfani da shi a cikin manyan fasahohin fasaha kamar masana'antar semiconductor, fasahar saka fim na bakin ciki, masana'antar hotovoltaic, da kayan aikin hoto na likita. An yi shi da molybdenum mai tsafta, tare da babban wurin narkewa, kyakkyawar wutar lantarki da yanayin zafi, wanda ke ba da damar maƙasudin molybdenum su tsaya tsayin daka a cikin matsanancin zafin jiki ko yanayin matsa lamba. Tsaftar kayan buƙatun molybdenum yawanci shine 99.9% ko 99.99%, kuma ƙayyadaddun bayanai sun haɗa da maƙasudin madauwari, maƙasudin faranti, da maƙasudin juyawa.

| Girma | Kamar yadda ake bukata |

| Wurin Asalin | Henan, Luoyang |

| Sunan Alama | FGD |

| Aikace-aikace | Likita, Masana'antu, Semiconductor |

| Siffar | Zagaye |

| Surface | goge |

| Tsafta | 99.95% Min |

| Kayan abu | Pure Mo |

| Yawan yawa | 10.2g/cm 3 |

| Babban abubuwan da aka gyara | Mo :99.95% |

| Abubuwan da ba su da tsabta ≤ | |

| Pb | 0.0005 |

| Fe | 0.0020 |

| S | 0.0050 |

| P | 0.0005 |

| C | 0.01 |

| Cr | 0.0010 |

| Al | 0.0015 |

| Cu | 0.0015 |

| K | 0.0080 |

| N | 0.003 |

| Sn | 0.0015 |

| Si | 0.0020 |

| Ca | 0.0015 |

| Na | 0.0020 |

| O | 0.008 |

| Ti | 0.0010 |

| Mg | 0.0010 |

| Kayan abu | Gwajin Zazzabi(℃) | Kauri faranti (mm) | Maganin zafi kafin gwaji |

| Mo | 1100 | 1.5 | 1200 ℃ / 1 h |

|

| 1450 | 2.0 | 1500 ℃ / 1 h |

|

| 1800 | 6.0 | 1800 ℃ / 1 h |

| TZM | 1100 | 1.5 | 1200 ℃ / 1 h |

|

| 1450 | 1.5 | 1500 ℃ / 1 h |

|

| 1800 | 3.5 | 1800 ℃ / 1 h |

| MLR | 1100 | 1.5 | 1700 ℃/3h |

|

| 1450 | 1.0 | 1700 ℃/3h |

|

| 1800 | 1.0 | 1700 ℃/3h |

1. Kamfaninmu yana cikin birnin Luoyang, lardin Henan. Luoyang yanki ne na samar da tungsten da ma'adinan molybdenum, don haka muna da cikakkiyar fa'ida cikin inganci da farashi;

2. Kamfaninmu yana da ma'aikatan fasaha tare da fiye da shekaru 15 na kwarewa, kuma muna samar da mafita da shawarwari don bukatun kowane abokin ciniki.

3. Dukkanin samfuranmu suna yin ingantaccen bincike mai inganci kafin a fitar da su.

4. Idan kun karɓi kayan da ba su da lahani, zaku iya tuntuɓar mu don maidowa.

1. Oxide

(molybdenum sesquioxide)

2. Ragewa

(Hanyar rage ƙwayar sinadarai don rage ƙwayar molybdenum)

3. Cakudawa da tace kayan kwalliya

(Daya daga cikin iyawar mu)

4. Latsawa

(Haɗuwa da latsa foda na ƙarfe)

5. Zuciya

(Ana mai zafi barbashi foda a cikin yanayin iskar gas mai kariya don samar da ƙananan shingen porosity sintered)

6. Yi tsari

(Yawan yawa da ƙarfin injiniyoyi na kayan yana ƙaruwa tare da matakin ƙirƙira)

7. Maganin zafi

(Ta hanyar maganin zafi, yana yiwuwa a daidaita damuwa na inji, rinjayar kayan abu, da kuma tabbatar da cewa karfe yana da sauƙin aiwatarwa a nan gaba)

8. Injiniya

(Layin samar da kayan aikin ƙwararru yana tabbatar da ƙimar cancantar samfuran daban-daban)

9. Tabbatar da inganci

(Ɗauki inganci, aminci, da tsarin kula da muhalli don tabbatarwa da ci gaba da haɓaka ingancin samfur da sabis)

10.Sake fa'ida

(Chemical, thermal, and in engineering treatment of production related ragi kayan da kuma sake yin fa'ida da tarkace kayayyakin iya taimaka kare albarkatun kasa)

Ana amfani da makasudin Molybdenum a cikin bututun X-ray don hoton likita, binciken masana'antu, da binciken kimiyya. Aikace-aikace don maƙasudin molybdenum sun kasance da farko wajen samar da hasken X-ray mai ƙarfi don gano hoto, kamar na'urar daukar hoto (CT) da na'urar rediyo.

Maƙasudin Molybdenum ana fifita su don babban wurin narkewar su, wanda ke ba su damar jure yanayin yanayin zafi da ake samarwa yayin samar da X-ray. Har ila yau, suna da kyakkyawan yanayin zafi, suna taimakawa wajen watsar da zafi da kuma tsawaita rayuwar bututun X-ray.

Baya ga hoton likita, ana amfani da maƙasudin molybdenum don gwaji mara lalacewa a aikace-aikacen masana'antu, kamar duba walda, bututu da abubuwan haɗin sararin samaniya. Ana kuma amfani da su a wuraren bincike waɗanda ke amfani da spectroscopy na X-ray fluorescence (XRF) don nazarin kayan aiki da gano asali.

Molybdenum yawanci ana amfani dashi azaman abin da aka yi niyya a cikin mammography saboda kyawawan kaddarorin sa don yin hoton ƙwayar nono. Molybdenum yana da ƙananan lambar atomic, wanda ke nufin raƙuman X-ray da yake samarwa sun dace don yin hoto mai laushi kamar ƙirjin. Molybdenum yana samar da halayen X-ray a ƙananan matakan makamashi, yana mai da su manufa don lura da bambance-bambance masu zurfi a cikin ƙwayar nono.

Bugu da ƙari, molybdenum yana da kyawawan kaddarorin thermal conductivity Properties, wanda ke da mahimmanci a cikin kayan aikin mammography inda ake maimaita bayyanar X-ray. Ƙarfin watsar da zafi yadda ya kamata yana taimakawa wajen tabbatar da kwanciyar hankali da aikin bututun X-ray na tsawon lokaci na amfani.

Gabaɗaya, yin amfani da molybdenum a matsayin abin da aka yi niyya a cikin mammography yana taimakawa haɓaka ingancin hoton nono ta hanyar samar da abubuwan da suka dace na X-ray don wannan takamaiman aikace-aikacen.

Maƙasudin sputter abu ne da ake amfani da shi a cikin tsarin tururi na zahiri (PVD) don samar da fina-finai na bakin ciki ko sutura akan abubuwan da ake amfani da su. A yayin aiwatar da sputtering, wani babban ƙarfin ion katako yana jefa bama-bamai akan maƙasudin sputtering, yana haifar da fitar da kwayoyin halitta ko kwayoyin halitta daga abin da aka nufa. Ana ajiye waɗannan ɓangarorin da aka fesa a kan ƙasa don samar da fim na bakin ciki tare da abun da ke ciki iri ɗaya kamar maƙasudin sputtering.

Ana yin maƙasudin ɓarna daga abubuwa daban-daban, gami da ƙarfe, gami, oxides da sauran mahadi, dangane da abubuwan da ake so na fim ɗin da aka ajiye. Zaɓin kayan da aka yi niyya na sputtering na iya yin tasiri sosai ga kaddarorin fim ɗin da aka samu, kamar ƙarfin wutar lantarki, kayan gani ko kayan maganadisu.

Ana amfani da maƙasudin zube a cikin masana'antu daban-daban kamar masana'antar semiconductor, suturar gani, da sel na hasken rana na bakin ciki. Matsakaicin ikon sarrafa abubuwan da ake hari akan sirara fim yana sanya su mahimmanci wajen samar da na'urorin lantarki da na gani na ci gaba.

Akwai la'akari da yawa da ke cikin zaɓi da amfani da maƙasudin molybdenum don ingantaccen aiki:

1. Tsarkakewa da abun da ke ciki: An zaɓi kayan aikin molybdenum mai tsabta mai tsabta don tabbatar da daidaito da amincin aikin sputtering. Ya kamata a daidaita abun da ke tattare da maƙasudin molybdenum zuwa takamaiman buƙatun sanya fim, kamar kayan fim ɗin da ake so da halayen mannewa.

2. Tsarin hatsi: Kula da tsarin hatsi na molybdenum manufa kamar yadda zai shafi tsarin sputtering da ingancin fim din da aka ajiye. Manufofin molybdenum masu kyau suna haɓaka daidaitattun sputtering iri ɗaya da aikin fim.

3. Maƙasudin lissafi da girman: Zaɓi maƙasudin maƙasudi da girman da ya dace don dacewa da tsarin sputtering da bukatun aiwatarwa. Ƙirar da aka yi niyya ya kamata ya tabbatar da ingantaccen sputtering da kuma daidaita fim ɗin a kan substrate.

4. Cooling da zafi mai zafi: Dole ne a yi amfani da hanyoyin kwantar da hankali da zafin jiki mai dacewa don sarrafa tasirin zafi a lokacin aikin sputtering. Wannan yana da mahimmanci ga maƙasudin molybdenum, saboda suna da sauƙin magance matsalolin zafi.

5. Siffofin watsawa: Inganta sigogi na sputtering kamar wutar lantarki, matsa lamba, da kwararar iskar gas don cimma kaddarorin fina-finai da ake so da ƙimar ajiya yayin da rage girman yazawar manufa da kuma tabbatar da aiwatar da dogon lokaci.

6. Kulawa da Kulawa: Bi shawarar molybdenum manufa kulawa, shigarwa da hanyoyin kiyayewa don tsawaita rayuwar sabis da kiyaye daidaitaccen aikin sputtering.

Ta hanyar yin la'akari da waɗannan abubuwan da kuma aiwatar da mafi kyawun ayyuka lokacin zabar da amfani da maƙasudin molybdenum, za a iya cimma mafi kyawun aikin sputtering, wanda ya haifar da babban ingancin fim na bakin ciki don aikace-aikace iri-iri.