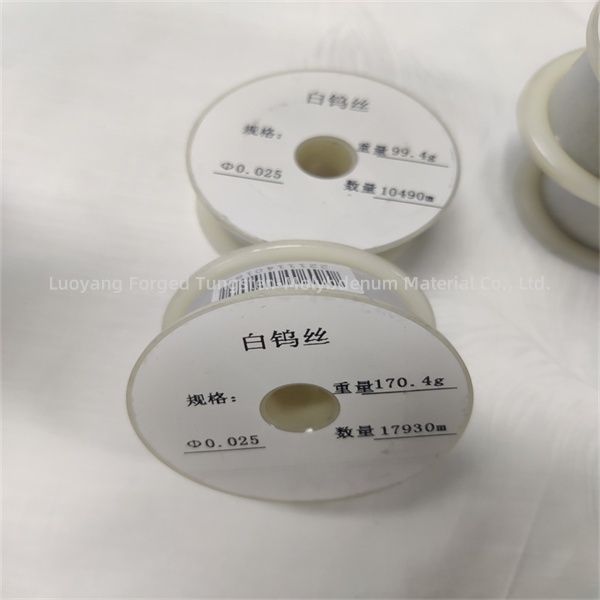

0.025mm tungsten waya 99.95% tsantsa tungsten filament

Baya ga yin amfani da su a cikin fitilun fitilu, ana amfani da waya ta tungsten sosai a matsayin wani abu mai fitar da haske a cikin wasu na'urorin lantarki kamar talabijin, nunin nuni, lasers, na'urorin lantarki, da bututun lantarki. Abubuwan da ke fitar da haske na tungsten waya a cikin waɗannan na'urori na iya samar da haske mai kyau, kwanciyar hankali mai kyau, da tsawon rayuwar hasken haske, biyan buƙatun aikace-aikace daban-daban.

| Diamita | Mai iya daidaitawa |

| Wurin Asalin | Henan, Luoyang |

| Sunan Alama | FGD |

| Aikace-aikace | Likitan, Abubuwan dumama, Masana'antu |

| Siffar | Kai tsaye |

| Surface | goge |

| Tsafta | 99.95% Min |

| Kayan abu | Tsaftace W |

| Yawan yawa | 19.3g/cm 3 |

| MOQ | 1 kg |

| Diamita na kayan silikid, mun | Nauyin sashin siliki na 200mm, MG | Mafi ƙarancin tsayi, m |

| 5≤d≤10 | 0.075 ~ 0.30 | 300 |

| 10≤d≤60 | :0.30 ~ 10.91 | 400 |

| 60<d≤100 | :10.91 ~ 30.30 | 350 |

| 100<d≤150 | :30.30 ~ 68.18 | 200 |

| 150<d≤200 | :68.18-121.20 | 100 |

| 200<d≤350 | :121.20 ~ 371.19 | 50 |

| 350<d≤700 | / | Daidai da tsayin 75g a nauyi |

| 700<d≤1800 | / | Daidai da tsayin 75g a nauyi |

| Diamita na siliki ld, μm | Nauyin sashin siliki na 200mm, MG | Weight na 200mm siliki sashi sabawa | Bambancin diamita % | |||

| 0 daraja | Ina daraja | Darasi na II | Ina daraja | Darasi na II | ||

| 5≤d≤10 | 0.075 ~ 0.30 | / | ±4 | ±5 | / | / |

| 10≤d≤18 | 0.30 ~ 0.98 | / | ±3 | ±4 | / | / |

| 18≤d≤40 | 0.98 ~ 4.85 | ±2 | ± 2.5 | ±3 | / | / |

| 40 d≤80 | 4.85 ~ 19.39 | ± 1.5 | ± 2.0 | ± 2.5 | / | / |

| 80 d≤300 | 19.39 ~ 272.71 | ± 1.0 | ± 1.5 | ± 2.0 | / | / |

| 300 d≤350 | 272.71~371.19 | / | ± 1.0 | ± 1.5 | / | / |

| 350 d≤500 | / | / | / | / | ± 1.5 | ± 2.0 |

| 500 d≤1800 | / | / | / | / | ± 1.0 | ± 1.5 |

1. Kamfaninmu yana cikin birnin Luoyang, lardin Henan. Luoyang yanki ne na samar da tungsten da ma'adinan molybdenum, don haka muna da cikakkiyar fa'ida cikin inganci da farashi;

2. Kamfaninmu yana da ma'aikatan fasaha tare da fiye da shekaru 15 na kwarewa, kuma muna samar da mafita da shawarwari don bukatun kowane abokin ciniki.

3. Dukkanin samfuranmu suna yin ingantaccen bincike mai inganci kafin a fitar da su.

4. Idan kun karɓi kayan da ba su da lahani, zaku iya tuntuɓar mu don maidowa.

1.Hanyar albarkatun kasa

2.maganin sinadarai

3. Rage zuwa tungsten foda

4.Matsawa da ɓacin rai

5. Zane

6.Annealing

7. Maganin saman

8. Quality Control

9. Marufi

1. Na'urorin lantarki da na'ura mai ba da hanya tsakanin hanyoyin sadarwa: Tungsten waya ana amfani da matsayin electron emitter da dumama element ga zafi electron bindigogi a cikin irin wannan aikace-aikace. Hakanan ana amfani da su sosai a cikin kayan aikin da ba za a iya amfani da su ba kamar bututun lantarki masu zafi, na'urorin lantarki na lantarki, da na'urorin ionization gas.

2. Filin walƙiya: Saboda ikonsa na fitar da haske mai haske a yanayin zafi mai yawa da kuma juriya ga karyewa, ana amfani da wayar tungsten sosai a matsayin tushen haske a cikin fitilun fitilu na gargajiya.

3. Resistance hita: Babban ma'anar narkewa da juriya mai zafi na waya tungsten ya sa ya zama kayan aiki mai mahimmanci don juriya masu zafi. Ana amfani da su sau da yawa a cikin gida da na'urori masu dumama wutar lantarki kamar su murhun wuta, tanda, da ƙarfe.

4. Welding da yanke: Tungsten waya yawanci amfani da electrode abu a high-makamashi waldi da yankan matakai kamar argon baka waldi, Laser yankan, da lantarki katako waldi. Babban wurin narkewa da juriya na lalata sun sa ya zama kyakkyawan zaɓi don ƙaddamarwar baka da sakin yanzu a cikin waɗannan matakan.

5. Chemical reactors: A wasu sinadarai reactors, tungsten wayoyi ana amfani a matsayin mai kara kuzari da kuma goyon bayan kayan don inganta dauki yadda ya dace da kwanciyar hankali.

Baya ga aikace-aikacen da ke sama, ana kuma amfani da wayar tungsten sosai a masana'antar masaku, sararin samaniya, masana'antar nukiliya, da kuma wuraren kiwon lafiya.

Ana buƙatar ƙayyade diamita na wayar tungsten bisa ga takamaiman yanayin aikace-aikacen. Gabaɗaya magana, mafi kyawun diamita, ƙarancin lalacewa da yayyaga wayar tungsten za ta samu, amma ƙarfin ɗaukar nauyi da rayuwar sabis zai ragu daidai. Saboda haka, wajibi ne a zabi bisa ga takamaiman bukatun.

Kayan kayan waya na tungsten yana da tasiri mai mahimmanci akan aikace-aikacen sa. Tungsten mai tsabta yana da mafi kyawun ƙarfin zafin jiki da juriya na lalata fiye da tungsten gami. Sabili da haka, a cikin yanayi inda ake buƙatar babban tsafta da juriya na lalata, ana bada shawara don zaɓar waya mai tsabta tungsten; Tungsten gami yana da mafi kyawun ƙarfi da ductility, yana mai da shi dacewa da wasu aikace-aikace na musamman kamar injin walƙiya, injin lantarki, da sauran filayen.

Lokacin narkewa na tungsten waya mai zafi a cikin injin ya dogara da ƙimar ƙawancen tungsten. Kuma dumama wayar tungsten a cikin iska yana samar da tungsten oxide. Matsakaicin narkewa na tungsten shine digiri 3410. Matsayin narkewar tungsten oxide, WO3, shine 1400-1600 digiri. A ƙarƙashin yanayin aiki na yau da kullun, zazzabi na filament yana kusa da digiri 2500, kuma WO3 yana yin tururi da sauri a wannan zafin jiki, yana haifar da filament ɗin da sauri narke cikin iska.