I-TZM alloy polished electrode rod esetshenziswa embonini ye-semiconductor

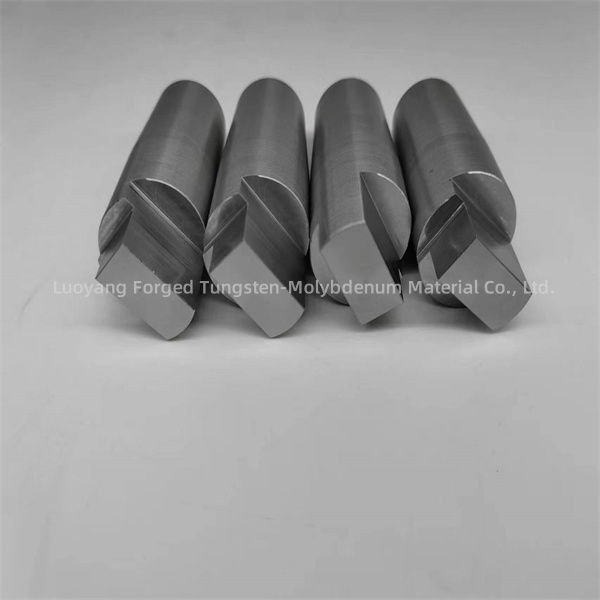

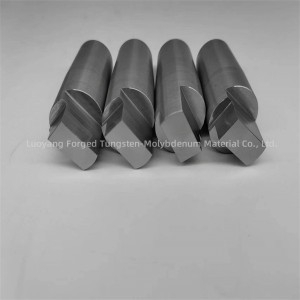

Ingxubevange ye-TZM iyimpahla esebenza kahle kakhulu ehlanganiswe ne-molybdenum (Mo), i-titanium (Ti) ne-zirconium (Zr). Igama elithi "TZM" lisuselwa ezinhlamvini zokuqala zezakhi ku-alloy. Le nhlanganisela yezinto inika okubalulekile amandla aphezulu ezinga lokushisa eliphezulu, ukuguquguquka okuhle kokushisa kanye nokumelana nokukhuphuka okushisayo, okuyenza ifanelekele izinhlelo zokusebenza ezinzima ezimbonini ezifana ne-aerospace, ukuzivikela, i-electronics kanye nokucubungula izinga lokushisa eliphezulu.

Ama-alloys e-TZM aziwa ngamandla awo okugcina izakhiwo zemishini emazingeni okushisa aphezulu, okuwenza abe wusizo ezinhlelweni ezibucayi ezidinga ukuzinza nokusebenza ngaphansi kwezimo ezimbi kakhulu.

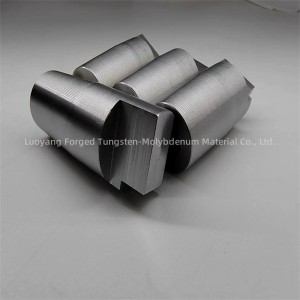

Izinga lokushisa lokwenziwa kabusha kwekristalu le-TZM (Titanium Zirconium Molybdenum) ingxubevange lilinganiselwa ku-1300°C kuya ku-1400°C (2372°F kuya ku-2552°F). Ngaphakathi kwaleli banga lokushisa, okusanhlamvu okugogekile kokubalulekile kuphinde kube yikristalu, kwakhe okusanhlamvu okusha okungacindezelwe futhi kuqede izingcindezi ezisele. Ukuqonda izinga lokushisa lokwenziwa kabusha kwekristalu kubalulekile ezinqubweni ezifana nokwelashwa kwe-anealing nokushisa, lapho i-microstructure kanye nezakhiwo zemishini zento ethuthukisiwe ukuze kusetshenziswe izinhlelo ezithile.

Ama-alloys e-TZM akhiwe nge-titanium (Ti), i-zirconium (Zr) kanye ne-molybdenum (Mo) futhi asetshenziswa ezinhlobonhlobo zezinga lokushisa eliphezulu ngenxa yezakhiwo zawo ezinhle kakhulu zemishini nezokushisa. Okunye ukusetshenziswa okuvamile kwe-TZM alloys kufaka phakathi:

1. I-Aerospace kanye Nokuvikela: I-TZM isetshenziswa endaweni yezindiza kanye nezicelo zokuvikela izingxenye ezidinga amandla ezinga lokushisa eliphezulu nokuzinza, njengamarokhethi, izingxenye zesakhiwo ezisezingeni eliphezulu nezinye izingxenye ezibalulekile.

2. Izingxenye zeziko lokushisa eliphezulu: I-TZM isetshenziswa ekwakhiweni kweziko lokushisa eliphezulu kwezensimbi, ukukhiqiza ingilazi, ukucubungula ama-semiconductor nezinye izimboni. Amandla ayo ezinga lokushisa eliphezulu nokuzinza kokushisa kubalulekile.

3. Izingxenye zikagesi neze-elekthronikhi: I-TZM isetshenziswa ezintweni ezithinta ugesi, osinki bokushisa nezinye izingxenye ze-elekthronikhi ngenxa yokuhamba kahle kukagesi kanye nezakhiwo ezishisayo.

4. Imishini yezokwelapha: I-TZM isetshenziswa emishinini yezokwelapha nasezinsizeni, ikakhulukazi izinhlelo zokusebenza ezidinga ukumelana nezinga lokushisa eliphezulu kanye nokuvumelana kwe-biocompatibility, njengamashubhu e-X-ray nokuvikela imisebe.

Sekukonke, ama-alloys e-TZM anenani elikhulu ngekhono lawo lokumelana namazinga okushisa aphezulu, ahlinzeke ngezinto ezinhle kakhulu zokufudumeza kanye nemishini, futhi agcine uzinzo ezindaweni ezinokhahlo, okuwenza afanelekele izinhlelo zokusebenza ezihlukahlukene ezibucayi.

Ingxoxo: 15138768150

WhatsApp: +86 15838517324

E-mail : jiajia@forgedmoly.com