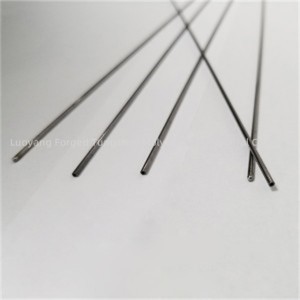

izinduku ze-tungsten ze-tungsten ezihlanzekile ezinobuso obuphucuziwe

Ukukhiqizwa kwamashubhu e-tungsten acwebezelisiwe kanye nezinduku kuhilela izinyathelo ezimbalwa ezibalulekile, okuhlanganisa ukukhiqizwa, ukwakheka kanye nokwelashwa okungaphezulu kwempahla ye-tungsten. Okulandelayo ukubuka kabanzi kwezindlela zokukhiqiza zamashubhu nezinduku ze-tungsten ezicwebezelisiwe:

1. Ukukhiqizwa kwe-Tungsten powder: Le nqubo iqala ukukhiqiza i-tungsten powder ngokunciphisa i-hydrogen ye-tungsten oxide noma i-ammonium paratungstate. Ukuhlanzeka nobukhulu bezinhlayiyana ze-tungsten powder yizici ezibalulekile ekunqumeni ikhwalithi yomkhiqizo wokugcina.

2. Ukuminyana kanye ne-sintering: Sebenzisa umshini wokunyathelisa we-hydraulic noma ezinye izindlela zokuhlanganisa ukuze ucindezele impushana ye-tungsten ibe yisimo osifunayo. I-tungsten ehlanganisiwe ibe isicwiliswa esithandweni sokushisa okuphezulu, ibophe izinhlayiya ndawonye ukuze zakhe isakhiwo esiqinile se-tungsten.

3. Ukubunjwa: I-tungsten ene-sintered iphinde icutshungulwe nge-extrusion, rolling noma umdwebo ukuze kutholwe umumo odingekayo nosayizi wamashubhu nezinduku.

4. Ukukhanda nokupholisha: Amashubhu e-tungsten akhiwe kanye nezinduku zenziwa ngomshini ukuze kuzuzwe usayizi odingekayo kanye nokuqedwa kwendawo. Lokhu kungase kuhlanganise ukuphenduka, ukugaya kanye nokupholishwa ukuze udale indawo ebushelelezi futhi epholishiwe.

5. Ukulawulwa Kwekhwalithi: Kuyo yonke inqubo yokukhiqiza, izinyathelo zokulawula ikhwalithi ziyasetshenziswa ukuze kuqinisekiswe ukuthi izinto ziyahlangabezana nezidingo zokuhlanzeka, usayizi kanye nokuqedwa kwendawo.

Kubalulekile ukuqaphela ukuthi ukukhiqiza amashubhu e-tungsten nezinduku ezinendawo epholishiwe kudinga ubuchwepheshe ekuphatheni i-tungsten ngoba iyimpahla eqinile futhi ephukayo. Ukwengeza, izinqubo zokucwenga nokupholisha zibalulekile ekufinyeleleni ukuphela kwendawo edingekayo kanye nokunemba kobukhulu.

Izindlela ezithile zokukhiqiza zingase zihluke kuye ngamandla omkhiqizi kanye nezidingo zokugcina zomkhiqizo. Uma unemibuzo ethile mayelana nezindlela zokukhiqiza zamashubhu nezinduku ze-tungsten ezipholishiwe, noma udinga imininingwane eyengeziwe, sicela ukhululeke ukubuza!

Amashubhu e-tungsten nezinduku ezinendawo epholishiwe zisetshenziswa ezimbonini ezahlukahlukene ngenxa yezakhiwo ezihlukile ze-tungsten. Nakhu okunye ukusetshenziswa okuvamile kwamashubhu e-tungsten nezinduku ezinendawo epholishiwe:

1. Izinto Zokushisisa: Izinti ze-Tungsten zisetshenziswa njengezici zokushisisa ezithandweni ezinokushisa okuphezulu, kanye nasezintweni ezifana nokuhwamuka kwe-vacuum kanye nezinqubo zokufafaza kuma-semiconductor kanye nezimboni ze-electronics.

2. I-Aerospace kanye Nokuvikela: Amashubhu nama-rod e-Tungsten asetshenziswa endaweni ye-aerospace nezinhlelo zokuvikela, okuhlanganisa izingxenye zemicibisholo, izingxenye zenjini ezishisa kakhulu, nezisindo eziphikisanayo ngenxa yokuminyana okukhulu kwe-tungsten namandla.

3. Imboni Yengilazi: Amashubhu e-tungsten asetshenziswa embonini yengilazi ukuze asetshenziswe njengama-electrode ancibilikisa ingilazi kanye nezakhiwo zokusekela ngenxa yezinga eliphakeme lokuncibilika le-tungsten kanye nokumelana nengilazi encibilikisiwe.

4. Amadivayisi Ezokwelapha: Ama-tungsten rod asetshenziswa emishinini yezokwelapha njengamashubhu e-X-ray nokuvikela imisebe ngenxa yekhono le-tungsten lokumunca imisebe kanye nokuvumelana kwayo ne-biocompatibility.

5. I-Electrical Discharge Machining (EDM): Izinduku ze-Tungsten zisetshenziswa njengama-electrode kumishini yokukhipha ugesi ngenxa yezinga eliphezulu lokuncibilika nokumelana nokugqoka.

6. Izingxenye Zesithando Sokushisa Okuphezulu: Amashubhu e-Tungsten nezinduku zisetshenziswa ekusetshenzisweni kwesithando sokushisa okuphezulu, okuhlanganisa izihlangu zokushisa, izinsimbi, kanye namashethi e-thermocouple ngenxa yephoyinti eliphezulu lokuncibilika kwe-tungsten kanye nokuhanjiswa kokushisa.

Indawo epholishiwe yezinti ze-tungsten namashubhu inganikeza isiphetho esingaphezulu esithuthukisiwe, ukumelana nokugqwala okuthuthukisiwe, nokusebenza okungcono kwezinye izinhlelo zokusebenza. Ukusetshenziswa okuqondile kwezindawo ze-tungsten ezipholishiwe zingahluka kuye ngezidingo zohlelo lokusebenza kanye nemboni.

Uma unemibuzo ethile mayelana nokusetshenziswa kwamashubhu e-tungsten nezinduku ezinendawo epholishiwe kuhlelo oluthile, zizwe ukhululekile ukubuza imininingwane eyengeziwe!

| Igama Lomkhiqizo | izinduku ze-tungsten ze-tungsten ezihlanzekile ezinobuso obuphucuziwe |

| Okubalulekile | W |

| Ukucaciswa | Kwenziwe ngokwezifiso |

| Ubuso | Isikhumba esimnyama, i-alkali egeziwe, epholishiwe. |

| Icebo | Sintering inqubo, machining |

| Iphuzu elincibilikayo | 3400 ℃ |

| Ukuminyana | 19.3g/cm3 |

Ingxoxo: 15138768150

WhatsApp: +86 15138745597