Izinga lokushisa eliphezulu elipholishelwe i-molybdenum indilinga ye-molybdenum ithagethi yokusetshenziswa kwemboni

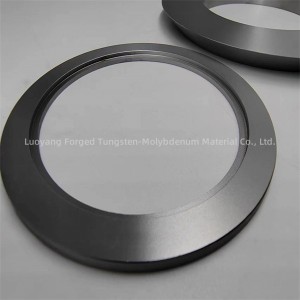

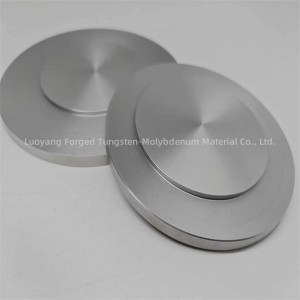

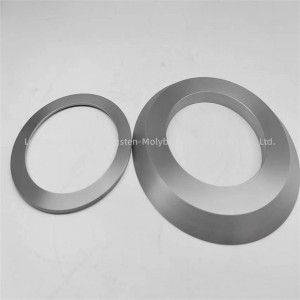

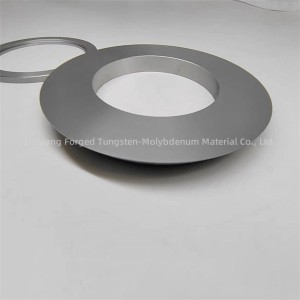

I-Molybdenum target material iwumsebenzi wezimboni osetshenziswa kakhulu emikhakheni yobuchwepheshe obuphezulu njengokukhiqizwa kwe-semiconductor, ubuchwepheshe bokufakwa kwefilimu emincane, imboni ye-photovoltaic, kanye nemishini yokucabanga yezokwelapha. Yenziwe nge-high-purity molybdenum, enephuzu eliphakeme lokuncibilika, ukuqhutshwa kahle kukagesi nokushisayo, okwenza izinhloso ze-molybdenum zihlale zizinzile ekushiseni okuphezulu noma ezindaweni ezicindezelayo. Ukuhlanzeka kwezinto ezihlosiwe ze-molybdenum kuvame ukuba ngu-99.9% noma u-99.99%, futhi ukucaciswa kuhlanganisa okuqondiwe okuyindilinga, okuqondiwe kwepuleti, kanye nezinhloso ezizungezisayo.

| Ubukhulu | Njengesidingo sakho |

| Le yindawo ka Origin | Henan, Luoyang |

| I gama le-brand | FGD |

| Isicelo | Ezokwelapha, Imboni, i-semiconductor |

| Isimo | Umjikelezo |

| Ubuso | Ipholishiwe |

| Ubumsulwa | 99.95% Min |

| Okubalulekile | Okuhlanzekile Mo |

| Ukuminyana | 10.2g/cm3 |

| Izingxenye eziyinhloko | Mo>99.95% |

| Okuqukethwe ukungcola≤ | |

| Pb | 0.0005 |

| Fe | 0.0020 |

| S | 0.0050 |

| P | 0.0005 |

| C | 0.01 |

| Cr | 0.0010 |

| Al | 0.0015 |

| Cu | 0.0015 |

| K | 0.0080 |

| N | 0.003 |

| Sn | 0.0015 |

| Si | 0.0020 |

| Ca | 0.0015 |

| Na | 0.0020 |

| O | 0.008 |

| Ti | 0.0010 |

| Mg | 0.0010 |

| Okubalulekile | Hlola izinga lokushisa(℃) | Ukuqina Kwepuleti(mm) | Ukwelashwa kokushisa kwangaphambi kokuhlolwa |

| Mo | 1100 | 1.5 | 1200℃/1h |

|

| 1450 | 2.0 | 1500℃/1h |

|

| 1800 | 6.0 | 1800℃/1h |

| I-TZM | 1100 | 1.5 | 1200℃/1h |

|

| 1450 | 1.5 | 1500℃/1h |

|

| 1800 | 3.5 | 1800℃/1h |

| I-MLR | 1100 | 1.5 | 1700℃/3h |

|

| 1450 | 1.0 | 1700℃/3h |

|

| 1800 | 1.0 | 1700℃/3h |

1. Imboni yethu itholakala eLuoyang City, esifundazweni saseHenan. I-Luoyang iyindawo yokukhiqiza yezimayini ze-tungsten ne-molybdenum, ngakho-ke sinezinzuzo eziphelele ngekhwalithi namanani;

2. Inkampani yethu inabasebenzi bezobuchwepheshe abaneminyaka engaphezu kwengu-15 yesipiliyoni, futhi sinikeza izixazululo neziphakamiso ezihlosiwe zezidingo zekhasimende ngalinye.

3. Yonke imikhiqizo yethu ihlolwa ngokuqinile ikhwalithi ngaphambi kokuthunyelwa kwamanye amazwe.

4. Uma uthola izimpahla ezingalungile, ungaxhumana nathi ukuze uthole imbuyiselo.

1. I-oxide

(i-molybdenum sesquioxide)

2. Ukuncishiswa

(Indlela yokunciphisa amakhemikhali yokunciphisa i-molybdenum powder)

3. Ukuxuba nokucwengisisa ama-alloys

(Elinye lamakhono ethu abalulekile)

4. Ukucindezela

(Ukuxuba nokucindezela impushana yensimbi)

5. Umshicileli

(Izinhlayiya zempushana zishiswa endaweni yegesi evikelayo ukuze kukhiqizwe amabhulokhi ane-porosity sintered ephansi)

6. Thatha isimo

(Ukuminyana namandla emishini akhuphuka ngezinga lokwakheka)

7. Ukwelashwa kokushisa

(Ngokwelashwa kokushisa, kungenzeka ukulinganisa ukucindezeleka kwemishini, kuthinte izakhiwo zezinto ezibonakalayo, nokuqinisekisa ukuthi insimbi kulula ukuyicubungula esikhathini esizayo)

8. Ukwenza imishini

(Ulayini wokukhiqiza wobungcweti uqinisekisa izinga lokufaneleka lemikhiqizo ehlukahlukene)

9. Ukuqinisekiswa kwekhwalithi

(Ukwamukela ikhwalithi, ukuphepha, kanye nezinhlelo zokuphatha imvelo ukuze kuqinisekiswe futhi kuthuthukiswe ngokuqhubekayo ikhwalithi yomkhiqizo nesevisi)

10.Recycle

(Ukwelashwa ngamakhemikhali, okushisayo, nokokusebenza kwezinto ezisalayo ezihlobene nokukhiqiza kanye nemikhiqizo yezinsalela ezigaywe kabusha kungasiza ukuvikela izinsiza zemvelo)

Okuqondiwe kwe-Molybdenum kuvame ukusetshenziswa kumashubhu e-X-ray ukuze kuthathwe izithombe zezokwelapha, ukuhlolwa kwezimboni, kanye nocwaningo lwesayensi. Izicelo zethagethi ye-molybdenum ziwukukhiqiza ama-X-reyi anamandla amakhulu okuthwebula izithombe, okufana nezikena ze-computed tomography (CT) kanye ne-radiography.

Okuqondiwe kwe-Molybdenum kuthandwa kakhulu ngenxa yezinga eliphezulu lokuncibilika, elivumela ukuthi zimelane nezinga lokushisa eliphezulu elikhiqizwa ngesikhathi sokukhiqizwa kwe-X-ray. Futhi banokusebenza okuhle kokushisa, okusiza ukuqeda ukushisa nokwandisa impilo ye-X-ray tube.

Ngokungeziwe emfanekisweni wezokwelapha, okuqondiwe kwe-molybdenum kusetshenziselwa ukuhlola okungabhubhisi ezinhlelweni zezimboni, njengokuhlola amashisela, amapayipi kanye nezingxenye ze-aerospace. Zibuye zisetshenziswe ezindaweni zokucwaninga ezisebenzisa i-X-ray fluorescence (XRF) spectroscopy ukuze kuhlaziywe izinto ezibonakalayo kanye nokuhlonza okuyisisekelo.

I-Molybdenum ivame ukusetshenziswa njengento ehlosiwe ku-mammography ngenxa yezakhiwo zayo ezithandekayo zokuthwebula izicubu zebele. I-Molybdenum inenombolo ye-athomu ephansi uma kuqhathaniswa, okusho ukuthi ama-X-reyi ayikhiqizayo alungele ukuthwebula izicubu ezithambile njengebele. I-Molybdenum ikhiqiza ama-X-reyi ayisici emazingeni aphansi wamandla, okuwenza alungele ukubona umehluko ocashile wokuminyana kwezicubu zamabele.

Ngaphezu kwalokho, i-molybdenum inezici ezinhle zokushisa ezishisayo, okubalulekile emishinini ye-mammography lapho ukuchayeka okuphindaphindiwe kwe-X-ray kuvamile. Ikhono lokuqeda ukushisa ngempumelelo lisiza ukugcina ukuzinza nokusebenza kwamashubhu e-X-ray esikhathini eside sokusetshenziswa.

Sekukonke, ukusetshenziswa kwe-molybdenum njengento eqondiwe ku-mammography kusiza ukuthuthukisa ikhwalithi yesithombe sesifuba ngokunikeza izakhiwo ezifanele ze-X-ray zalolu hlelo lokusebenza oluthile.

Ithagethi ye-sputter yinto esetshenziswa enqubweni ye-physical vapor deposition (PVD) ukwenza amafilimu amancanyana noma ama-coatings kuma-substrates. Ngesikhathi senqubo yokufafaza, i-ion enamandla amakhulu ibhomuza ithagethi yokufafaza, ibangele ukuthi ama-athomu noma ama-molecule akhishwe kwinto eqondiwe. Lezi zinhlayiya ezifuthwe zibe sezifakwa ku-substrate ukuze zenze ifilimu elincanyana elinokwakheka okufanayo nokuhlosiwe okufafaza ngakho.

Okuhlosiwe kwe-sputtering kwenziwa ngezinto ezihlukahlukene, okuhlanganisa izinsimbi, ama-alloys, ama-oxides nezinye izinhlanganisela, kuye ngezakhiwo ezifunwayo zefilimu efakiwe. Ukukhethwa kwezinto ezihlosiwe ze-sputtering kungathinta kakhulu izakhiwo zefilimu eliwumphumela, njengokuhamba kukagesi, izakhiwo zokubona noma izici kazibuthe.

Izinhloso ze-sputtering zisetshenziswa kabanzi ezimbonini ezahlukahlukene ezifana nokukhiqiza i-semiconductor, i-optical coating, kanye namaseli elanga efilimu emincane. Ukulawula okunembayo kwezinhloso ze-sputtering phezu kokufakwa kwefilimu ezacile kubenza babaluleke kakhulu ekukhiqizweni kwemishini ethuthukisiwe ye-elekthronikhi ne-optical.

Kunokucatshangelwa okuningana okuhilelekile ekukhetheni nasekusebenziseni okuqondiwe kwe-molybdenum ukuze kusebenze kahle:

1. Ukuhlanzeka nokubunjwa: Izinto ezihlosiwe ze-high-purity molybdenum zikhethwa ukuze kuqinisekiswe ukusebenza kwe-sputtering okungaguquki nokuthembekile. Ukwakheka kwethagethi ye-molybdenum kufanele kuhambisane nezidingo ezithile zokubekwa kwefilimu, njengezakhiwo zefilimu ezifunwayo nezici zokunamathela.

2. Isakhiwo sokusanhlamvu: Naka ukwakheka okusanhlamvu kwethagethi ye-molybdenum njengoba izophazamisa inqubo yokufafaza kanye nekhwalithi yefilimu efakiwe. Okuqondiwe kwe-fine-grained molybdenum kuthuthukisa ukufana kwe-sputtering nokusebenza kwefilimu.

3. Ijiyomethri eqondiwe nosayizi: Khetha i-geometry eqondiwe nosayizi ukuze uhambisane nesistimu ye-sputtering kanye nezidingo zenqubo. Idizayini eqondiwe kufanele iqinisekise ukuphalaza okuphumelelayo kanye nokufakwa kwefilimu okufanayo ku-substrate.

4. Ukupholisa nokukhishwa kokushisa: Izindlela ezifanelekile zokupholisa kanye nokukhipha ukushisa kufanele kusetshenziswe ukuphatha imiphumela yokushisa ngesikhathi senqubo yokufafaza. Lokhu kubaluleke kakhulu ezintweni ezihlosiwe ze-molybdenum, njengoba zisengozini yezinkinga ezihlobene nokushisa.

5. Amapharamitha we-Sputtering: Lungiselela amapharamitha wokuphalaza njengamandla, ingcindezi, nokugeleza kwegesi ukuze uzuze izici zefilimu ezifiselekayo kanye namazinga okubekwa ngenkathi unciphisa ukuguguleka okuhlosiwe futhi uqinisekisa ukusebenza okuhlosiwe kwesikhathi eside.

6. Ukunakekela Nokuphatha: Landela ukuphathwa kwethagethi ye-molybdenum enconyiwe, ukufakwa kanye nezinqubo zokunakekela ukuze unwebe impilo yayo yesevisi futhi ugcine ukusebenza kwe-sputtering okungaguquki.

Ngokucabangela lezi zici nokusebenzisa izinqubo ezingcono kakhulu lapho kukhethwa futhi kusetshenziswa okuqondiwe kwe-molybdenum, ukusebenza kwe-sputtering okuphelele kungafinyelelwa, okuholela ekufakweni kwefilimu emincane yekhwalithi ephezulu yezinhlelo zokusebenza ezihlukahlukene.