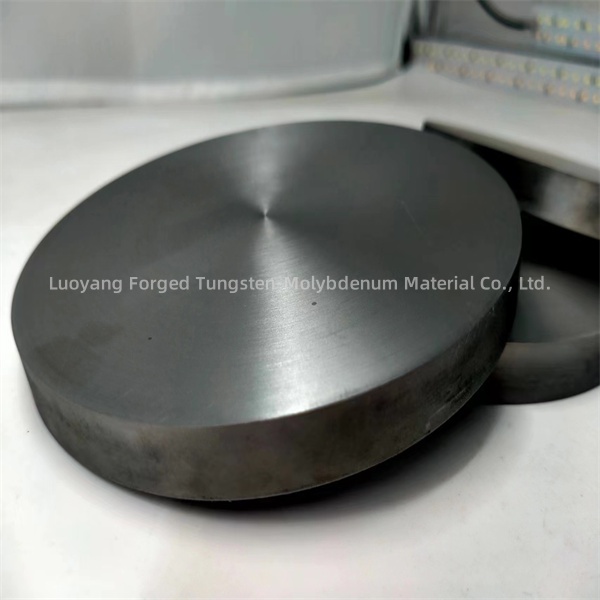

Ithagethi ye-titanium sputtering yokuhlanzeka okuphezulu kwe-vacuum coating

Okuhlosiwe kwe-sputter yizinto ezihlanzeke kakhulu ezisetshenziswa ezinqubweni ze-physical vapor deposition (PVD), ikakhulukazi ubuchwepheshe bokukhipha amanzi. Lezi zinto zisetshenziselwa ukwenza amafilimu amancanyana kuma-substrates ezimboni ezihlukahlukene, okuhlanganisa ukukhiqizwa kwe-semiconductor, ama-optical coatings, nokufakwa kwefilimu emincane yemishini kagesi.

Izinto ezihlosiwe ze-sputter zingenziwa ngezinto ezihlukahlukene nezinhlanganisela, okuhlanganisa izinsimbi, ama-alloys, ama-oxides nama-nitride. Ukukhethwa kwezinto ezihlosiwe ze-sputter kuncike ezicini ezithile ezidingekayo ukuze kufakwe ifilimu encane, njengokuhamba kukagesi, izakhiwo ze-optical, ubulukhuni kanye nokumelana namakhemikhali.

Okuhlosiwe okujwayelekile kokuphalaza kuhlanganisa izinsimbi ezifana ne-titanium, i-aluminium nethusi, kanye nezinhlanganisela ezifana ne-indium tin oxide (ITO) nama-oxide ensimbi ahlukahlukene. Ukukhetha into ehlosiwe ye-sputtering efanelekile kubalulekile ekuzuzeni izici ezifiselekayo kanye nokusebenza kwezingubo zefilimu ezacile.

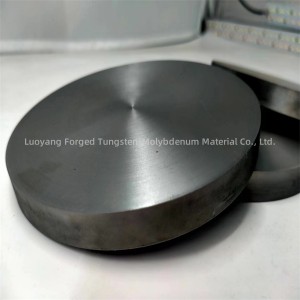

Okuhlosiwe kokuthela kuza ngosayizi abahlukahlukene kuye ngezidingo ezithile zenqubo yokubeka ifilimu elincanyana kanye nemishini yokufafaza. Usayizi wethagethi ye-sputtering bungasukela kumasentimitha ambalwa ukuya kumashumi amasentimitha ububanzi, futhi ukujiya kungahluka.

Ubukhulu bethagethi ye-sputtering bunqunywa izici ezifana nosayizi we-substrate okufanele igcotshwe, ukumiswa kwesistimu yokufafaza, nezinga lokubeka elifiswayo kanye nokufana. Ukwengeza, usayizi wethagethi ye-sputtering ungase uthintwe izidingo ezithile zohlelo lokusebenza lwefilimu elincanyana, njengendawo ezogcotshwa kanye nemingcele yenqubo iyonke.

Ekugcineni, usayizi wethagethi ye-sputter uyakhethwa ukuze kuqinisekiswe ukubekwa kwefilimu ngendlela ephumelelayo nefanayo ku-substrate, ehlangabezana nezidingo ezithile zenqubo yokumboza ifilimu elincanyana ekukhiqizeni ama-semiconductor, ama-optical coatings nezinye izinhlelo zokusebenza ezihlobene.

Kunezindlela eziningana zokwandisa izinga lokufafaza ngenqubo yokufafaza:

1. Ukuthuthukisa Amandla Nokucindezela: Ukulungisa imingcele yamandla nengcindezi ohlelweni lokufafaza kungase kube nomthelela izinga lokufafaza. Ukwandisa amandla nokuthuthukisa izimo zengcindezi kungathuthukisa izinga lokufafaza, okuholela ekufakweni ngokushesha kwefilimu elincanyana.

2. Izinto Eziqondiwe kanye Nejiyomethri: Ukusebenzisa okuhlosiwe kwe-sputtering ngokwakhiwa kwento ethuthukisiwe kanye nejometri kungathuthukisa izinga lokufafaza. Izinga eliphezulu, okuhloswe ngalo ukuphalaza okuklanywe kahle kungathuthukisa ukusebenza kahle kwe-sputtering futhi kuholele kumazinga aphezulu okubeka.

3. Ukulungiswa Kwendawo Okuhlosiwe: Ukuhlanzwa kahle kanye nokulungiswa kwendawo okuhloswe kuyo ukuchelela kungase kube nomthelela ekwandeni kwamazinga okufafaza. Ukuqinisekisa ukuthi indawo okuqondiswe kuyo ayinakho ukungcola nama-oxide kungathuthukisa ukusebenza kahle kokuchaphaza.

4. I-Substrate Temperature: Ukulawula izinga lokushisa le-substrate kungaba nomthelela izinga lokufafaza. Kwezinye izimo, ukuphakamisa izinga lokushisa elingaphansi kwe-substrate phakathi kwebanga elithile kungaholela emazingeni akhuphukayo okufafaza kanye nekhwalithi yefilimu ethuthukisiwe.

5. Ukugeleza Nokubunjwa Kwegesi: Ukuthuthukisa ukugeleza kwegesi nokwakheka ekamelweni lokufafaza kungase kuthinte izinga lokufafaza. Ukulungisa amazinga okugeleza kwegesi nokusebenzisa izingxube ezifanele zegesi yokufafaza kungathuthukisa ukusebenza kahle kwenqubo yokufafaza.

Ngokucubungula lezi zici ngokucophelela nokuthuthukisa imingcele yenqubo yokufafaza, kungenzeka ukwandisa izinga lokufafaza futhi kuthuthukiswe ukusebenza kahle okuphelele kokumiswa kwefilimu emincane ekufakweni kwe-sputtering.

Ingxoxo: 15138768150

WhatsApp: +86 15838517324

E-mail : jiajia@forgedmoly.com