I-alloy esindayo i-tungsten enentambo ye-electrode Ubulukhuni obuphezulu nokuminyana

Ukukhiqizwa kwama-electrode anentambo ye-tungsten kuhilela izinyathelo ezimbalwa ezibalulekile zokuqinisekisa umkhiqizo wekhwalithi ephezulu, ohlala isikhathi eside. Okulandelayo ukubuka kabanzi kwezindlela zokukhiqiza ezijwayelekile zama-electrode anentambo ye-tungsten:

1. Ukukhetha impahla eluhlaza: Inqubo iqala ngokukhetha izinto zokusetshenziswa zekhwalithi ephezulu ze-tungsten. I-Tungsten yaziwa ngobulukhuni bayo obukhethekile kanye nephoyinti lokuncibilika eliphezulu, okuyenza ilungele ama-electrodes anentambo lapho ukuqina nokumelana nokushisa kuyadingeka.

2. Ukulungiswa kwempushana: Lungiselela izinto zokusetshenziswa ze-tungsten ezikhethiwe zibe yimpushana ngokunciphisa i-hydrogen noma ukunciphisa i-ammonium paratungstate (APT). Le powder iyinto eyinhloko yokukhiqizwa kwama-electrode anentambo.

3. Ukuxuba nokuhlanganisa: Impushana ye-Tungsten ixutshwa nezinye izakhi ze-alloying ukuze kutholwe izici ezifiselekayo, njengokukhula kokuqina nokuminyana. Impushana exubile ibe isicindezelwa esimeni esifiswayo kusetshenziswa amasu okucindezela okuphezulu okufana nokucindezela okubandayo kwe-isostatic (CIP) noma ukubumba.

4. I-Sintering: I-tungsten powder ehlanganisiwe ingaphansi kwenqubo ye-sintering ephezulu yokushisa endaweni elawulwayo (imvamisa endaweni engenalutho noma ye-hydrogen). I-Sintering isiza ukuhlanganisa izinhlayiya ze-tungsten ukuze zakhe isakhiwo esiminyene nesiqinile.

5. Umshini kanye nokulutha: Ngemva kokucwiliswa, impahla ye-tungsten yenziwa ngomshini ukuze ibe nobukhulu bokugcina futhi icushwe ukuze kwakheke umumo we-electrode oyifunayo. Ubuchwepheshe bokwenza imishini busetshenziswa ukuqinisekisa ukunemba kwezici zentambo.

6. Ukwelashwa okungaphezulu: Ama-electrode anemicu angathola ukwelashwa okungaphezulu okunjengokugaya, ukupholishwa noma ukunamathiswa ukuze kuthuthukiswe ukusebenza kwawo kanye nokuguga nokubola.

7. Ukulawulwa Kwekhwalithi: Kuyo yonke inqubo yokukhiqiza, izinyathelo zokulawula ikhwalithi ziyasetshenziswa ukuze kuqinisekiswe ukuthi ama-electrode anentambo ahlangabezana nobunzima obudingekayo, ukuminyana, ukunemba kobukhulu kanye nokunye ukucaciswa kwepharamitha ebalulekile.

Ngokulandela lezi zinyathelo zokukhiqiza, abakhiqizi bangakhiqiza ama-electrode anentambo ye-tungsten enobulukhuni obuphezulu, ukuminyana nokuqina, okubenza bafanelekele izicelo ezidingekayo ezimbonini ezifana nokushisela, ukwenza insimbi kanye nokukhipha ugesi kagesi (EDM).

Ama-electrode anentambo ye-Tungsten asetshenziswa ezinqubweni ezahlukahlukene zezimboni ngenxa yokuqina kwawo okuphezulu, ukuminyana nokuqina kwawo. Ezinye izinhlelo zokusebenza ezijwayelekile zifaka:

1. I-Resistance Welding: Ama-electrode anentambo ye-Tungsten asetshenziswa enkambweni yokushisela yokumelana njengamaphoyinti okuxhumana ukuze kuqhutshwe okwamanje futhi kukhiqize ukushisa ukuxhuma izingxenye zensimbi. Ukuqina okuphezulu kwe-Tungsten nokumelana nokushisa kuyenza ifanelekele ukumelana nezinga lokushisa eliphezulu nezingcindezi zemishini ezihlangatshezwana nazo emisebenzini yokushisela.

2. I-Electric Discharge Machining (EDM): Ku-EDM, ama-electrode anentambo ye-tungsten asetshenziswa njengezingxenye zethuluzi lokubunjwa kanye nomshini wokwenza izinto eziphathekayo. Ukuqina kwe-Tungsten nokungagugi kuyenza ibe yisinqumo esihle kakhulu sokukhiqiza izingxenye eziyinkimbinkimbi zomshini ngenqubo ye-EDM.

3. I-Spark corrosion: Ama-electrode anentambo ye-Tungsten asetshenziswa ekugqwaleni kwenhlansi noma ezinqubweni zokubumba njengezinto ze-electrode zokudala izimo eziyinkimbinkimbi nezici ezintweni zokusebenza zensimbi. Ukuminyana okuphezulu kwe-Tungsten nokusebenza okushisayo kunika amandla ukususwa kwezinto ezisebenzayo kanye nomshini onembile ekusetshenzisweni kokuguguleka kwenhlansi.

4. Ukwakhiwa Kwensimbi Nokugxiviza: Ama-electrode anentambo ye-Tungsten asetshenziswa ekwenzeni insimbi kanye nokusebenza kokunyathela ukuze kusizwe ukwakha, ukubhoboza noma ukusika amashidi ensimbi nezingxenye. Ukuqina nokuqina kwe-Tungsten kuyenza ifanelekele ukumelana namandla emishini ahilelekile enqubweni yokwakhiwa kwensimbi.

5. I-Glass kanye Ne-Ceramic Processing: Ama-electrode anentambo ye-Tungsten nawo asetshenziswa engilazini nasezinsizeni zokucubungula ze-ceramic zokubhoboza, ukusika noma ukubunjwa kwalezi zinto eziphukayo. Ukuqina kwe-Tungsten nokumelana nokugqokwa kuyenza ilungele ukunemba kwemishini embonini yengilazi neyobumba.

6. I-Aerospace kanye Nokuvikela: Ama-electrode anentambo ye-Tungsten asetshenziswa ezinqubweni ezehlukene zokukhiqiza nokunakekela emikhakheni ye-aerospace neyokuvikela, okuhlanganisa ukushisela, ukukhanda imishini nokwakhiwa kwensimbi, okudinga ukusebenza okuphezulu kanye nezingxenye zamathuluzi ezihlala isikhathi eside.

Sekukonke, ubulukhuni obuphezulu, ukuminyana, nokuqina kwama-electrode anentambo ye-tungsten kuwenza afaneleke kahle ezinhlotsheni zezinhlelo zokusebenza zezimboni, ikakhulukazi izinqubo ezibandakanya amazinga okushisa aphezulu, ukucindezelwa komshini, kanye nezidingo zokunemba kwemishini.

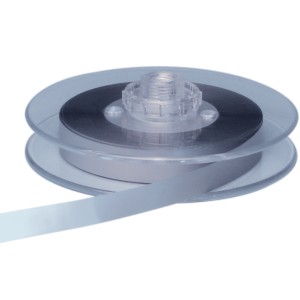

| Igama Lomkhiqizo | I-Tungsten Threaded Electrode |

| Okubalulekile | W1 |

| Ukucaciswa | Kwenziwe ngokwezifiso |

| Ubuso | Isikhumba esimnyama, i-alkali egeziwe, epholishiwe. |

| Icebo | Sintering inqubo, machining |

| Iphuzu elincibilikayo | 3400 ℃ |

| Ukuminyana | 19.3g/cm3 |

Ingxoxo: 15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com