I-Mo La Alloy Plate eyenziwe ngokwezifiso Ye-Industrial Furnace Outlet

Ukukhiqizwa kwamashidi engxube ye-molybdenum-lanthanum (Mo-La) ngokuvamile kuhilela uchungechunge lwezinqubo zokukhiqiza. Lezi zinqubo zingabandakanya: Ukulungiswa kwempahla eluhlaza:

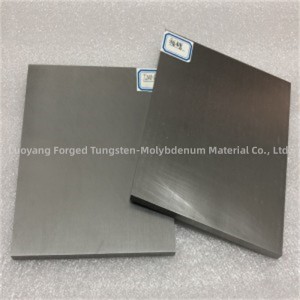

Isinyathelo sokuqala sihilela ukuthola izinto zokusetshenziswa ezidingekayo, njenge-molybdenum ne-lanthanum, ngendlela yezimpushana noma ezinye izinto zokusetshenziswa ezifanele. Lezi zinto zokusetshenziswa zikhethwa ngokusekelwe ekuhlanzekeni kwazo kanye nokwakheka kwe-alloy oyifunayo. Ukuhlanganisa Nokuxuba: Izimpushana ze-molybdenum ne-lanthanum zixutshwa ndawonye ngezilinganiso ezinembile ukuze kutholwe ukwakheka kwe-alloy oyifunayo. Ingxube ixubene kahle ukuze kuqinisekiswe ukusatshalaliswa kwezithako. Ukuhlangana: Ingxube yempushana ehlanganisiwe ibe isihlanganiswa ngaphansi kwengcindezi ephezulu ukuze yakhe umzimba oluhlaza ominyene futhi ohlangene. Ukucindezela kungafinyelelwa kusetshenziswa amasu anjengokucindezela kwe-isostatic okubandayo (CIP) noma ukucindezela uniaxial. I-Sintering: Umzimba oluhlaza ushiswa esithandweni sokushisa okuphezulu ngaphansi komkhathi olawulwayo ukuze kuzuzwe ukuhlangana okuqinile kwesimo phakathi kwezinhlayiya ze-molybdenum ne-lanthanum. Le nqubo iholela ekwakhekeni kwe-alloy ye-Mo-La eminyene futhi ehlanganiswe ngokugcwele. I-Hot Rolling: I-Sintered Mo-La alloy material ibe sengaphansi kwenqubo yokugoqa okushisayo ukuze kutholwe ukujiya okudingekile kanye nezakhiwo zemishini. Inqubo yokugoqa okushisayo ihlanganisa ukudlulisa impahla ochungechungeni lwamaroli emazingeni okushisa aphezulu ukuze kuncishiswe ukujiya kwayo futhi kuthuthukiswe i-microstructure yayo. I-Annealing: Ngemva kokuginqika okushisayo, ipuleti le-Mo-La alloy lingase libe nenqubo yokuqeda ukucindezelwa kwangaphakathi futhi liqhubeke licolise ukwakheka kwalo okuncane. Ukufakwa kwe-anneal ngokuvamile kwenziwa ezingeni lokushisa elithile kanye nesikhathi esilawulwayo. Ukwelashwa Okungaphezulu Nokuqedwa: Amapuleti e-Mo-La alloy angabhekana nokwelashwa okwengeziwe okungaphezulu okufana nokucotshwa, ukucwiliswa kwemishini noma ukupholishwa ukuze kuzuzwe ukuphela kwendawo edingekayo kanye nokubekezelelwa kwe-dimensional. Ukulawulwa kwekhwalithi nokuhlolwa: Kuyo yonke inqubo yokukhiqiza, amashidi e-Mo-La alloy abhekana nezinyathelo eziqinile zokulawula ikhwalithi nokuhlolwa ukuze kuqinisekiswe ukuthi izakhiwo zawo zemishini, i-microstructure kanye nokwakheka kwamakhemikhali kuhlangabezana nezidingo ezishiwo.

Izindlela zokukhiqiza ezingenhla ziwumbono jikelele futhi zingahluka kuye ngamasu athile okukhiqiza nezinto zokusebenza ezisetshenziswa abakhiqizi abahlukene. Izinyathelo eziqondile namapharamitha ahilelekile ekukhiqizweni kwamashidi engxubevange ye-Mo-La kuzoncika ezintweni ezifana nosayizi weshidi elidingekayo, izici zomshini kanye nokusetshenziswa kokugcina.

Amashidi e-alloy e-Molybdenum-lanthanum (Mo-La) asetshenziswa emisebenzini ehlukahlukene yezimboni ngenxa yezakhiwo zawo ezihlukile. Amapuleti e-Mo-La alloy aziwa ngamandla awo okushisa okuphezulu, ukuhamba kahle kwe-thermal, ukumelana nokushaqeka okushisayo kanye nokusebenza kahle kakhulu. Lezi zakhiwo zenza amapuleti e-Mo-La alloy afanele izindawo zokushisa okuphezulu kanye nezicelo ezidingayo ezifana nalezi:

Izingxenye zesithando somlilo: Amashidi e-alloy e-Mo-La asetshenziswa ekwakhiweni kweziko lezimboni kanye nemishini yokwelapha ukushisa ngenxa yokukwazi ukumelana namazinga okushisa aphezulu kanye nokuhamba ngebhayisikili okushisayo. Imboni ye-Aerospace: Amapuleti e-alloy e-Mo-La asetshenziswa ezingxenyeni ze-aerospace, okuhlanganisa imibhobho yamarokhethi, amakamelo omlilo nezinye izingxenye zesakhiwo esinezinga lokushisa eliphezulu. Imboni yengilazi: Amashidi e-Mo-La alloy asetshenziswa enqubweni yokukhiqiza ingilazi, ikakhulukazi ekukhiqizeni isikhunta sengilazi, ama-stirrers kanye nokuqinisa amathangi ngenxa yokumelana kwawo nengilazi encibilikisiwe kanye nokushaqeka okushisayo. Ama-Radiators nama-Heat Exchanger: Amapuleti e-Mo-La alloy asetshenziswa ezinhlelweni zokuphatha ezishisayo okuhlanganisa osinki bokushisa bemishini kagesi kanye nezishintshisi zokushisa zezinqubo zokushisa okuphezulu. Ithagethi ye-Sputtering: Ipuleti le-alloy ye-Mo-La lisetshenziswa njengethagethi yokufaka ifilimu ekukhiqizweni kwe-semiconductor kanye ne-electronics. Oxhumana Nabo Kagesi: Amapuleti e-Mo-La alloy asetshenziswa kothintana nabo kagesi kanye nama-circuit breaker ngenxa ye-conductivity yabo kagesi enhle kanye nokumelana nokuguguleka kwe-arc. Izicelo Zezokwelapha NezeNuclear: Amashidi engxubevange ye-Mo-La asetshenziswa ekuvikeleni emisebeni nasezinsizeni zokushisa okuphezulu ezimbonini zezokwelapha nezenuzi.

Sekukonke, amashidi engxubevange ye-Mo-La aziswa ngenhlanganisela yawo yamandla ezinga lokushisa eliphezulu, ukuqhutshwa kwe-thermal, kanye nokumelana nezindawo ezinokhahlo, okuwenza abaluleke kakhulu emikhakheni eyahlukene yezimboni.

Ingxoxo: 15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com