Ibha ye-electrode ye-W1 ecocekileyo ye-tungsten yokuwelda

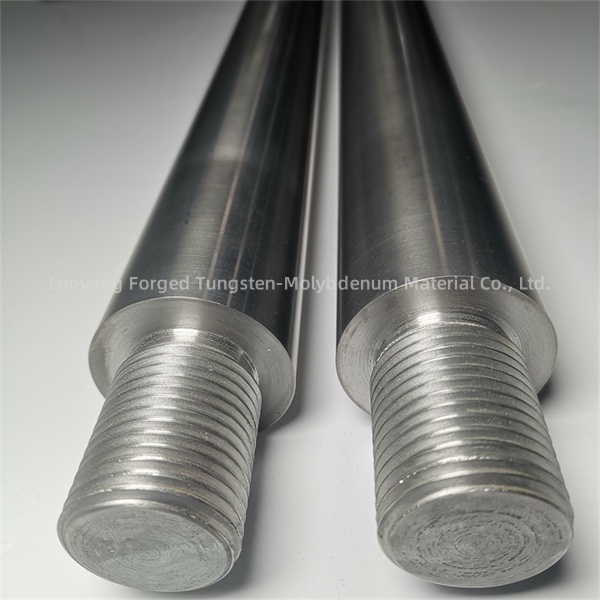

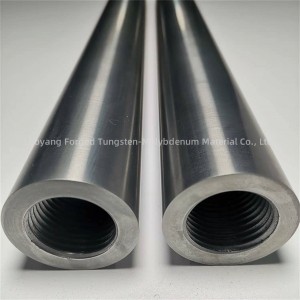

Intonga ye-electrode ye-Tungsten yintonga eqhelekileyo ye-electrode eneempawu ezinje ngeqondo eliphezulu lokunyibilika, uxinaniso oluphezulu, ubunzima obuphezulu, kunye ne-coefficient ephantsi yokwandiswa kwe-thermal. Ngoko ke, isetyenziswa ngokubanzi kumsebenzi we-electrode kwiindawo eziphakamileyo zokushisa. Phakathi kwazo, i-tungsten oxide electrode rods isetyenziswa ngokubanzi kwiinkalo zenkqubo ezifana ne-argon arc welding kunye ne-plasma yokusika ngenxa yobomi babo benkonzo ende kunye nokuchasana kwe-oxidation.

| Imilinganiselo | Njengemizobo yakho |

| Indawo yeMvelaphi | Luoyang, Henan |

| Igama lebrand | FGD |

| Isicelo | Ishishini |

| Umphezulu | Ilungisiwe |

| Ubunyulu | 99.95% |

| Izinto eziphathekayo | I-tungsten ecocekileyo |

| Ukuxinana | 19.3g/cm3 |

| Indawo yokunyibilika | 3400℃ |

| Indawo yokusetyenziswa | Vacuum okusingqongileyo |

| Ubushushu bokusetyenziswa | 1600-2500℃ |

| Amacandelo aphambili | W-99.95% |

| Umxholo wokungcola≤ | |

| Pb | 0.0005 |

| Fe | 0.0020 |

| S | 0.0050 |

| P | 0.0005 |

| C | 0.01 |

| Cr | 0.0010 |

| Al | 0.0015 |

| Cu | 0.0015 |

| K | 0.0080 |

| N | 0.003 |

| Sn | 0.0015 |

| Si | 0.0020 |

| Ca | 0.0015 |

| Na | 0.0020 |

| O | 0.008 |

| Ti | 0.0010 |

| Mg | 0.0010 |

1. Umzi-mveliso wethu useLuoyang City, kwiPhondo laseHenan. I-Luoyang yindawo yemveliso yemigodi ye-tungsten kunye ne-molybdenum, ngoko ke sineenzuzo ezipheleleyo kumgangatho kunye nexabiso;

2. Inkampani yethu inabasebenzi bezobugcisa abaneminyaka engaphezu kwe-15 yamava, kwaye sibonelela ngezisombululo ezijoliswe kuzo kunye neengcebiso kwiimfuno zomthengi ngamnye.

3. Zonke iimveliso zethu zihlolwa ngokungqongqo umgangatho phambi kokuba zithunyelwe kumazwe angaphandle.

4. Ukuba ufumana iimpahla ezineziphene, unokuqhagamshelana nathi ukuze ubuyiselwe imali.

1. Ukuxuba izithako

2. ukucofa ukwenza

3. Sintering ukungena

4. kubanda-umsebenzi

I-aerospace, i-metallurgy, oomatshini kunye namanye amashishini: ii-electrode ze-Tungsten zisetyenziswa ngokubanzi kwi-aerospace, i-metallurgy, oomatshini kunye namanye amashishini okuvelisa izinto ezinobushushu obuphezulu, i-alloys zombane, i-electrode yombane, izixhobo ze-microelectronic, njl. ukuchaneka okuphezulu kakhulu kunye nokuthembeka.

Ukongeza, iintonga ze-tungsten electrode zikwasetyenziselwa ukwenza iifilaments kunye nokusika ngesantya esiphezulu sentsimbi yealloy, i-superhard molds, kunye nokwenza izixhobo zokukhanya kunye neekhemikhali. Kwintsimi yezempi, iintonga ze-tungsten electrode nazo zinezicelo ezibalulekileyo.

Oku kubangelwa ubukhulu becala ngokugqithisileyo, ukudlula uluhlu oluvumelekileyo lwangoku lwe-electrode ye-tungsten; Ukukhetha okungafanelekanga kwee-electrodes ze-tungsten, ezifana nobubanzi obungahambelaniyo okanye imodeli; Ukugaya okungafanelekanga kwee-electrodes ze-tungsten kukhokelela ekunyibilikeni; Kwaye imiba ngobuchule be-welding, njengokunxibelelana rhoqo kunye nokuvutha phakathi kweengcebiso ze-tungsten kunye nezixhobo ezisisiseko, ezikhokelela ekunxibeni okukhawulezileyo kunye nokukrazula.

1. Ukungcola okanye i-oxidation: I-conductivity ye-tungsten iyancipha njengoko iqondo le-oxidation kumphezulu walo linyuka. Ukuba indawo engaphezulu yentonga ye-tungsten iqokelela ubuninzi bokungcola okanye ayicocwanga ixesha elide, iya kuchaphazela ukuqhuba kwayo.

2. Ukucoceka okuphantsi: Ukuba kukho ezinye iintsimbi ezingcolileyo kwizinto eziphathekayo ze-tungsten, zinokukhawulela ukuhamba kwangoku kwaye zenze intonga ye-tungsten ingabikho.

3. I-sintering engalinganiyo: Ngexesha lokwenziwa kweentonga ze-tungsten, i-sintering iyadingeka. Ukuba i-sintering ayilingani, iimpendulo ezimbi zinokuthi zenzeke kumphezulu, ezinokukhokelela ekunciphiseni ukuqhutyelwa kwentonga ye-tungsten.