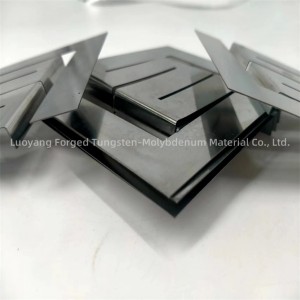

molybdenum sheet molybdenum ipleyiti molybdenum gasket

Ukuveliswa kwamaphepha e-molybdenum kunye ne-gaskets kubandakanya la manyathelo alandelayo:

1. Imveliso ye-molybdenum powder: Le nkqubo iqala ukuvelisa i-molybdenum powder ngokunciphisa i-hydrogen ye-molybdenum oxide kunye nezinye iteknoloji. Oku kubangela ukubunjwa kwepowder ecocekileyo ye-molybdenum.

2. I-Powder compaction: I-molybdenum powder icinezelwe ibe yifom eqinileyo isebenzisa iindlela ezifana nokucofa okubandayo okanye ukucinezela kwe-isostatic. Eli nyathelo linceda ukwenza umzimba oluhlaza kunye nesimo esifunwayo kunye nobukhulu.

3. I-Sintering: Umzimba oluhlaza ufakwe kwiqondo lokushisa eliphezulu kwi-atmospheric elawulwayo, ngokuqhelekileyo kwindawo ye-vacuum okanye i-hydrogen. I-Sintering inceda ukubopha i-molybdenum particles kunye, ukudala i-molybdenum eqinile kunye ne-dense sheet okanye izinto ze-gasket.

4. I-Hot rolling: Ukuze kuveliswe iipleyiti ze-molybdenum, i-sintered molybdenum imathiriyeli ishushu iqhutywe ukuze ifezekise ubuninzi obufunekayo kunye nokuphela komhlaba. Inkqubo ibandakanya ukufudumeza izinto kumaqondo aphezulu kunye nokudlula kwi-rolling mill ukunciphisa ubukhulu bayo kunye nokuphucula iimpawu zayo zomatshini.

5. Ukutshiza: Ipleyiti ye-molybdenum eqengqelekayo iye isetyenziswe ukuphumeza imilinganiselo yokugqibela kunye nokugqiba komphezulu ofunekayo kwisicelo esithile. Oku kunokubandakanya iinkqubo ezifana nokusika, ukungqusha okanye ukusila.

6. Ukulawulwa komgangatho: Kuyo yonke inkqubo yokuvelisa, amanyathelo okulawula umgangatho aphunyezwa ukuze kuqinisekiswe ukuba iipleyiti ze-molybdenum kunye ne-gaskets zidibana neenkcukacha ezifunekayo, kubandakanywa ukuchaneka komgangatho, umgangatho womhlaba, kunye neempawu eziphathekayo ezifana namandla kunye ne-ductility.

Ngokulandela la manyathelo okuvelisa, abavelisi banokuvelisa iipleyiti eziphezulu ze-molybdenum kunye neegaskets ezifanelekileyo kwiqondo lokushisa eliphezulu kunye nezicelo zoxinzelelo, ukubonelela ukutywinwa okuthembekileyo kunye nokusebenza kwiindawo ezifunwayo.

Iipleyiti ze-Molybdenum kunye ne-gaskets zineendlela ezininzi zokusetyenziswa, ngakumbi kumashishini apho ukushisa okuphezulu kunye noxinzelelo oluphezulu lweendawo eziqhelekileyo. Olunye usetyenziso oluthile lweepleyiti zemolybdenum kunye neegaskets ziquka:

1. Isithando somlilo esiphezulu: Iipleyiti ze-Molybdenum zisetyenziselwa izinto zokufudumeza, izikhuselo zokushisa kunye nezakhiwo zesakhiwo kwiziko lokushisa eliphezulu kunye nezixhobo zonyango lokushisa. Indawo ephezulu yokunyibilika kwe-Molybdenum kunye ne-thermal conductivity egqwesileyo yenza ukuba ilungele ezi zicelo.

2. I-Aerospace kunye noKhuseleko: I-Molybdenum gaskets isetyenziselwa kwi-aerospace kunye nezicelo zokukhusela ukubonelela ukutywinwa okuthembekileyo kwiqondo lokushisa eliphezulu kunye neendawo zoxinzelelo oluphezulu, njengeenjini zeenqwelo-moya, iinkqubo ze-rocket propulsion kunye nezixhobo zomkhosi ezisebenza kakhulu.

3. Ukuveliswa kombane: Iipleyiti zeMolybdenum kunye neegaskets zisetyenziswa kumaziko okuvelisa amandla, kubandakanywa amaziko ombane enyukliya, kumacandelo e-reactor, iinkqubo zomoya wobushushu obuphezulu, kunye nezinye izixhobo ezibalulekileyo ezifuna ukutywinwa okuthembekileyo kunye nokumelana nomhlwa.

4. Ukulungiswa kweekhemikhali: I-Molybdenum gaskets isetyenziselwa izixhobo zokulungisa iikhemikhali, ezifana ne-reactors, iinqanawa kunye neenkqubo zombhobho, ukubonelela ngokutywinwa okusebenzayo kwiindawo ezinobungozi kunye nobushushu obuphezulu.

5. Ukuveliswa kwe-Semiconductor: Amaphepha e-molybdenum asetyenziselwa ukuveliswa kwezixhobo ze-semiconductor kwaye asetyenziswa njenge-substrates, i-heat sink kunye namacandelo ezixhobo zokulungisa ukushisa okuphezulu kwi-semiconductor yokuvelisa.

Kwezi zicelo, iipleyiti ze-molybdenum kunye ne-gaskets zibonelela ngeempawu ezibalaseleyo zokushisa kunye nezomatshini, kunye nokuchasana nokugqwala kunye namaqondo okushisa aphezulu, okwenza ukuba zilungele ukusetyenziswa kwiindawo ezinzima zoshishino.

| Igama lemveliso | Iphepha leMolybdenum Molybdenum Gasket |

| Izinto eziphathekayo | Mo1 |

| Inkcazo | Customized |

| Umphezulu | Ulusu olumnyama, ialkali ihlanjiwe, igudisiwe. |

| Ubuchwephesha | inkqubo Sintering, machining |

| Indawo yokunyibilika | 2600℃ |

| Ukuxinana | 10.2g/cm3 |

Wechat: 15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com