Ucoceko oluphezulu lwe-titanium sputtering ithagethi yokugquma ivacuum

Iithagethi ze-sputter zizixhobo ezicocekileyo ezisetyenziswa kwiinkqubo zokubeka umphunga womzimba (PVD), ngokukodwa iteknoloji yokutshiza. Ezi zixhobo zisetyenziselwa ukwenza iifilimu ezicekethekileyo kwii-substrates kumashishini ahlukeneyo, kubandakanywa ukwenziwa kwe-semiconductor, i-optical coatings, kunye nokubekwa kwefilimu encinci yezixhobo zombane.

Izinto ezijoliswe kwi-sputter zingenziwa kwizinto ezahlukeneyo kunye neekhompawundi, kuquka isinyithi, i-alloys, i-oxides kunye ne-nitrides. Ukukhethwa kwezinto ezijoliswe kwi-sputter kuxhomekeke kwiimpawu ezithile ezifunekayo kwi-coating yefilimu encinci, efana ne-conductivity yombane, iipropati ze-optical, ukuqina kunye nokumelana nemichiza.

Iithagethi ze-sputtering eziqhelekileyo ziquka isinyithi ezifana ne-titanium, i-aluminium kunye nobhedu, kunye neekhompawundi ezifana ne-indium tin oxide (ITO) kunye nee-oxide zetsimbi ezahlukeneyo. Ukukhetha imathiriyeli efanelekileyo yokutshiza kubalulekile ekufezekiseni iimpawu ezinqwenelekayo kunye nokusebenza kweengubo zefilimu ezincinci.

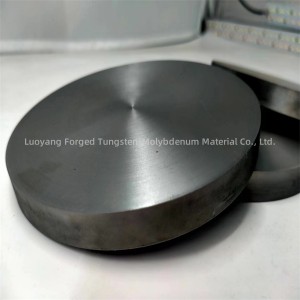

Iithagethi ze-sputtering ziza ngobukhulu obahlukeneyo ngokuxhomekeke kwiimfuno ezithile zenkqubo yokubeka ifilimu encinci kunye nezixhobo zokutshiza. Ubungakanani bethagethi ye-sputtering inokuqala ukusuka kwiisentimitha ezimbalwa ukuya kumashumi eesentimitha ububanzi, kwaye ubukhulu bunokwahluka.

Ubungakanani bethagethi yokutshiza bumiselwa yimiba efana nobukhulu be-substrate eza kugqunywa, ukucwangciswa kwenkqubo yokutshiza, kunye nesantya esifunwayo sokubekwa kunye nokufana. Ukongezelela, ubungakanani bethagethi ye-sputtering inokuchaphazeleka kwiimfuno ezithile zesicelo sefilimu encinci, njengendawo yokufakwa kunye neepharamitha zenkqubo yonke.

Ekugqibeleni, ubukhulu bethagethi ye-sputter ikhethiwe ukuze kuqinisekiswe ngokufanelekileyo kunye nokufakwa okufanayo kwefilimu kwi-substrate, ukuhlangabezana neemfuno ezithile zenkqubo yokugquma ifilimu ebhityileyo kwimveliso ye-semiconductor, i-optical coatings kunye nezinye izicelo ezinxulumene nazo.

Kukho iindlela ezininzi zokunyusa izinga lokutshiza kwinkqubo yokutshiza:

1. Amandla kunye nokuPhuculwa koxinzelelo: Ukulungelelanisa amandla kunye neeparitha zoxinzelelo kwi-sputtering system inokuchaphazela izinga lokutshiza. Ukwandisa amandla kunye nokuphucula iimeko zoxinzelelo kunokunyusa izinga lokutshiza, okukhokelela ekufakweni ngokukhawuleza kwefilimu encinci.

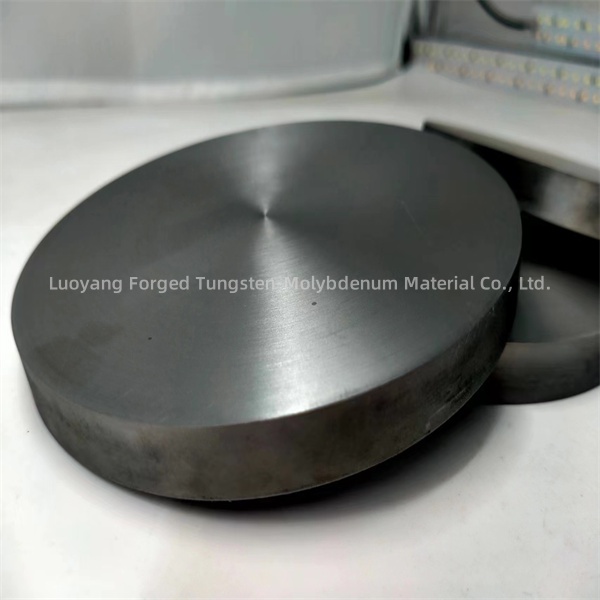

2. Izinto ekujoliswe kuzo kunye nejometri: Ukusebenzisa iithagethi ze-sputtering kunye nokwakheka kwezinto eziphuculweyo kunye nejometri kunokuphucula izinga lokutshiza. Umgangatho ophezulu, iithagethi zokutshiza eziyilwe kakuhle zinokuphucula ukusebenza kakuhle kokutshiza kwaye zikhokelele kumazinga aphezulu okubekwa.

3. ULungiselelo lweNdawo ekuJoliswe kuyo: Ukucocwa ngokufanelekileyo kunye nokulungiswa kwendawo ekujoliswe kuyo ku-sputtering kunokufaka isandla ekwandeni kwamazinga okuhlamba. Ukuqinisekisa ukuba indawo ekujoliswe kuyo ikhululekile kwizinto ezingcolisayo kunye neeoksidi kunokuphucula ukusebenza kakuhle kokutshiza.

4. Ubushushu be-substrate: Ukulawula ubushushu be-substrate kunokuchaphazela izinga lokutshiza. Kwezinye iimeko, ukuphakamisa ubushushu be-substrate ngaphakathi koluhlu oluthile kunokukhokelela ekunyuseni kwamazinga okuhlamba kunye nokuphucula umgangatho wefilimu.

5. Ukuhamba kwegesi kunye nokuBunjwa: Ukuphucula ukuhamba kwegesi kunye nokubunjwa kwigumbi lokutshiza kunokuchaphazela izinga lokutshiza. Ukulungelelanisa amazinga okuhamba kwerhasi kunye nokusebenzisa imixube yerhasi efanelekileyo yokutshiza kunokuphucula ukusebenza kakuhle kwenkqubo yokutshiza.

Ngokuqwalasela ngononophelo ezi zinto kunye nokwandisa iiparameters zenkqubo yokutshiza, kunokwenzeka ukunyusa izinga lokutshiza kunye nokuphucula ukusebenza kakuhle kwefilimu ebhityileyo ekufakeni izicelo zokutshiza.

Wechat: 15138768150

WhatsApp: +86 15838517324

E-mail : jiajia@forgedmoly.com