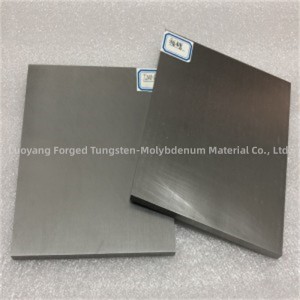

Ipleyiti yeMo La Alloy eyenzelwe iMo ye-Industrial Furnace Outlet

Ukuveliswa kwe-molybdenum-lanthanum (i-Mo-La) alloy sheets ngokuqhelekileyo kubandakanya uchungechunge lweenkqubo zokuvelisa. Ezi nkqubo zinokubandakanya: Ukulungiselela imathiriyeli ekrwada:

Isinyathelo sokuqala sibandakanya ukufumana izinto eziyimfuneko ezifunekayo, ezifana ne-molybdenum kunye ne-lanthanum, ngendlela yomgubo okanye ezinye izinto ezifanelekileyo ezifanelekileyo. Ezi zinto zikhethiweyo zikhethwa ngokusekelwe kubunyulu bazo kunye nokwakheka kwe-alloy efunwayo. Ukudibanisa kunye nokuxuba: I-molybdenum kunye ne-lanthanum powders zixutywe kunye ngomlinganiselo ochanekileyo ukufumana ukubunjwa kwe-alloy efunekayo. Umxube uxutywe ngokucokisekileyo ukuqinisekisa ngokulinganayo ukusabalalisa izithako. Ukuxinwa: Umxube we powder odibeneyo emva koko uhlanganiswe phantsi koxinzelelo oluphezulu ukwenza umzimba oluhlaza kunye odibeneyo. I-Compaction inokufezekiswa ngokusebenzisa ubuchule obufana ne-cold isostatic pressing (CIP) okanye i-uniaxial pressing. I-Sintering: Umzimba oluhlaza ufakwe kwi-furnace yobushushu obuphezulu phantsi kwe-atmosphere elawulwayo ukuze ufezekise ukudibanisa kwe-slid-state diffusion phakathi kwe-molybdenum kunye ne-lanthanum particles. Le nkqubo ibangela ukubunjwa kwe-alloy eshinyeneyo kwaye idityaniswe ngokupheleleyo ye-Mo-La. Ukuqengqeleka okushushu: Isixhobo se-Sintered Mo-La alloy ke siphantsi kwenkqubo eshushu yokuqengqeleka ukufumana ubukhulu obufunekayo kunye neempawu zoomatshini. Inkqubo yokufudumala eshushu ibandakanya ukugqithiswa kwezinto ngokusebenzisa uluhlu lwemiqulu kwiqondo lokushisa eliphezulu ukunciphisa ubukhulu bayo kunye nokuphucula i-microstructure yayo. I-Annealing: Emva kokuqengqeleka okushushu, ipleyiti ye-alloy ye-Mo-La inokungena kwinkqubo yokuphelisa uxinzelelo lwangaphakathi kunye nokuphucula ngakumbi ubume bayo be-microstructure. I-Anealing idla ngokuqhutyelwa kwiqondo lokushisa elithile kunye nexesha elilawulwayo. Ukunyangwa koMphezulu kunye nokuQeda: Iipleyiti ze-alloy ze-Mo-La zinokungena kunyango olongezelelweyo lomphezulu olufana nokuchola, umatshini okanye ukupolishwa ukufezekisa umphezulu ofunekayo wokugqitywa kunye nokunyamezelwa kobukhulu. Ulawulo lomgangatho kunye novavanyo: Kuyo yonke inkqubo yokuvelisa, amashiti e-Mo-La alloy afumana amanyathelo angqongqo olawulo lomgangatho kunye novavanyo lokuqinisekisa ukuba iipropathi zabo zoomatshini, i-microstructure kunye nokwakheka kweekhemikhali ziyahlangabezana neemfuno ezichaziweyo.

Ezi ndlela zokuvelisa zingentla zijongwe ngokubanzi kwaye zinokwahluka ngokuxhomekeke kubuchule obuthile bokuvelisa kunye nezixhobo ezisetyenziswa ngabavelisi abohlukeneyo. Amanyathelo achanekileyo kunye neeparitha ezibandakanyekayo ekuvelisweni kwamaphepha e-alloy e-Mo-La aya kuxhomekeka kwizinto ezifana nobukhulu bephepha elifunekayo, iimpawu zomatshini kunye nokusetyenziswa kokuphela.

Amaphepha e-alloy e-Molybdenum-lanthanum (Mo-La) asetyenziswa kwizicelo ezahlukeneyo zoshishino ngenxa yeempawu zabo ezizodwa. Iipleyiti ze-alloy ze-Mo-La ziyaziwa ngamandla abo aphezulu obushushu, ukuhanjiswa kakuhle kwe-thermal, ukuxhathisa ukothuka kwe-thermal kunye nokusebenza kakuhle. Ezi zakhiwo zenza iipleyiti ze-alloy ze-Mo-La zilungele iimeko zokushisa okuphezulu kunye nezicelo ezifunayo ezifana nezi:

Amacandelo omlilo: Amaphepha e-alloy e-Mo-La asetyenziswa ekwakhiweni kweziko loshishino kunye nezixhobo zonyango lobushushu ngenxa yokukwazi ukumelana nobushushu obuphezulu kunye nokuhamba ngebhayisikile ye-thermal. Umzi-mveliso we-aerospace: Iipleyiti ze-alloy ze-Mo-La zisetyenziswa kumacandelo e-aerospace, kubandakanywa nemibhobho ye-rocket, amagumbi okutsha kunye namanye amacandelo obushushu obuphezulu. Ushishino lweglasi: Amaphepha e-alloy e-Mo-La asetyenziswa kwinkqubo yokwenziwa kweglasi, ngakumbi kwimveliso yeglasi yokubumba, ii-stirrers kunye neziqinisekiso zetanki ngenxa yokuchasa iglasi etyhidiweyo kunye nomothuko we-thermal. I-Radiators kunye ne-Heat Exchangers: Iipleyiti ze-alloy ze-Mo-La zisetyenziswa kwizicelo zolawulo lwe-thermal ezibandakanya ii-sinks zokushisa zezixhobo ze-elektroniki kunye nokutshintsha ubushushu kwiinkqubo eziphezulu zokushisa. Ithagethi ye-Sputtering: Ipleyiti ye-alloy ye-Mo-La isetyenziswa njengethagethi yokutshiza yokubekwa kwefilim ebhityileyo kwi-semiconductor kunye nokuveliswa kombane. IiNxibelelwano zoMbane: Iipleyiti ze-alloy ze-Mo-La zisetyenziselwa uqhagamshelwano lombane kunye neziqhekeza zeesekethe ngenxa yokuqhuba kakuhle kombane kunye nokuchasana nokukhukuliseka kwe-arc. Usetyenziso lwezoNyango neNyukliya: Amaphepha engxubevange e-Mo-La asetyenziswa ekukhuseleni ukusasazeka kwemitha kunye nezixhobo zobushushu obuphezulu kumashishini ezonyango nawenyukliya.

Ngokubanzi, amashiti e-alloy e-Mo-La axatyiswe ngokudityaniswa kwawo kwamandla obushushu obuphezulu, ukuhanjiswa kwe-thermal, kunye nokuchasana nemekobume erhabaxa, nto leyo ebenza babe yimfuneko kwiinkalo ezahlukeneyo zoshishino.

Wechat: 15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com