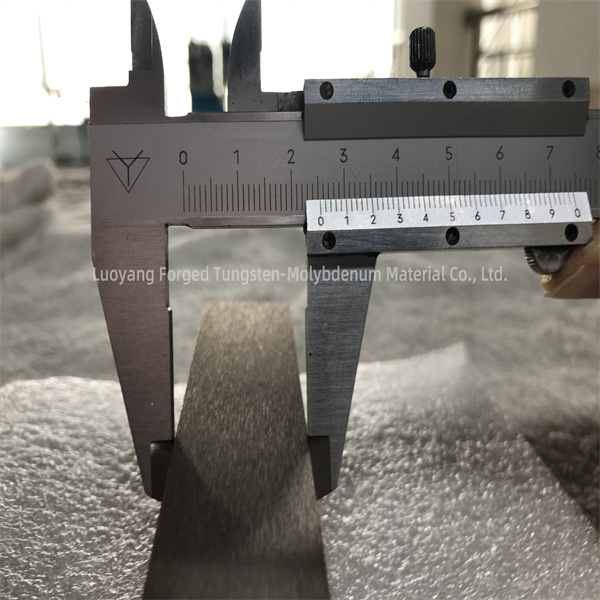

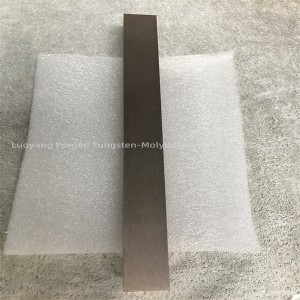

W90Cu10 tungsten copper bar for EDM

Yes, copper tungsten can be used as an electrode material in electrical discharge machining (EDM). Copper-tungsten is a composite material composed of copper and tungsten, which has excellent electrical and thermal conductivity, high melting point and good wear resistance. These properties make it suitable for EDM applications.

When using copper-tungsten electrodes for EDM, it is important to consider factors such as the specific composition of the copper-tungsten material, the type of workpiece material being machined, and EDM parameters such as discharge current, pulse duration, and flushing conditions. Proper selection and setup of EDM machines is also critical to achieving the desired machining results.

Overall, copper tungsten is a viable and commonly used EDM electrode material, especially in applications requiring high wear resistance and thermal conductivity.

The hardness of tungsten-copper composites can vary depending on the specific composition and processing method. Generally speaking, tungsten copper alloys have high hardness, making them suitable for applications where wear resistance and strength are important.

The hardness of tungsten copper is usually measured using the Rockwell or Vickers hardness scale. Tungsten-copper composites have hardness values ranging from 70 HRC (Rockwell C) to over 90 HRC, indicating high resistance to deformation and wear.

The hardness of tungsten copper makes it ideal for a variety of demanding applications, including electrical contacts, welding electrodes and EDM electrodes, where the material is subject to high mechanical and thermal stresses.

Yes, tungsten is known for its extreme hardness. In fact, tungsten has the highest tensile strength of any pure metal and is known for its exceptional hardness and wear resistance. This makes it a valuable material with a wide range of applications, including cutting tools, high temperature applications and components requiring high wear resistance.

Wechat:15138768150

WhatsApp: +86 15838517324

E-mail : jiajia@forgedmoly.com