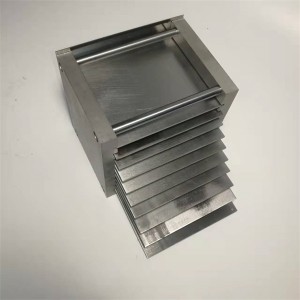

melting pot tungsten crucible for high temperature furnace

Tungsten crucible is a type of metal tungsten product, mainly divided into two types: sintering and stamping. The preparation process of tungsten crucible includes spinning type, stamping type, etc. These processes make tungsten crucible have high density, low surface roughness, good tensile strength and hardness, while the production cost is relatively low, and the product price is also relatively low.

The wide application of tungsten crucibles benefits from their excellent physical and chemical properties, including high melting point, high strength, good corrosion resistance, and wear resistance.

| Dimensions | As your requirement |

| Place of Origin | Luoyang, Henan |

| Brand Name | FGD |

| Application | Industry |

| Surface | Polished |

| Purity | 99.95% Min |

| Material | Pure tungsten |

| Density | 19.3g/cm3 |

| melting point | 3400℃ |

| Usage environment | Vacuum environment |

| Usage temperature | 1600-2500℃ |

| Main components |

W>99.95% |

|

Impurity content≤ |

|

|

Pb |

0.0005 |

|

Fe |

0.0020 |

|

S |

0.0050 |

|

P |

0.0005 |

|

C |

0.01 |

|

Cr |

0.0010 |

|

Al |

0.0015 |

|

Cu |

0.0015 |

|

K |

0.0080 |

|

N |

0.003 |

|

Sn |

0.0015 |

|

Si |

0.0020 |

|

Ca |

0.0015 |

|

Na |

0.0020 |

|

O |

0.008 |

|

Ti |

0.0010 |

|

Mg |

0.0010 |

|

Material |

100% recrystallization temperature ℃ |

(Annealing time: 1 hour)) |

|

|

Deformation degree=90% |

Deformation degree=99.99% |

|

Pure W |

1350 |

- |

|

WVM |

- |

2000 |

|

WL10 |

1500 |

2500 |

|

WL15 |

1550 |

2600 |

|

WRe05 |

1700 |

- |

|

WRe26 |

1750 |

- |

1. Our factory is located in Luoyang City, Henan Province. Luoyang is a production area for tungsten and molybdenum mines, so we have absolute advantages in quality and price;

2. Our company has technical personnel with over 15 years of experience, and we provide targeted solutions and suggestions for each customer's needs.

3. All of our products undergo strict quality inspection before being exported.

4. If you receive defective goods, you can contact us for a refund.

1. Prepare tungsten powder

(Firstly, prepare tungsten powder and screen it to separate coarse and fine tungsten powder)

2. Combined batch

(Batch processing of tungsten powder with the same chemical composition but from different production processes)

3. isostatic pressing

(Place the combined tungsten powder in a sealed container filled with liquid, and gradually pressurize it through a pressurization system to reduce the distance between molecules, increase density, and improve the physical properties of the material without changing its appearance)

4. Rough billet machining

(After completing the isostatic pressing, rough billet processing is carried out)

5. Intermediate frequency sintering

(Place the processed rough billet into an intermediate frequency sintering furnace for sintering operation)

6. Fine car processing

(Turning the sintered product to obtain precise dimensions and shapes)

7. Inspect packaging

(Inspect the processed tungsten crucible and package it after passing the inspection)

Quartz glass melting: Tungsten crucibles are also widely used in quartz glass melting furnaces. As one of the important equipment for melting quartz glass, their high temperature strength and corrosion resistance enable quartz glass to melt and form the desired shape in high temperature environments.

The deformation of the crucible is caused by uneven expansion of different parts of the crucible due to excessive and uneven heating. Rapid and uneven heating of the crucible should be avoided.

Recommended temperature range is 1600-2500 degrees Celsius.