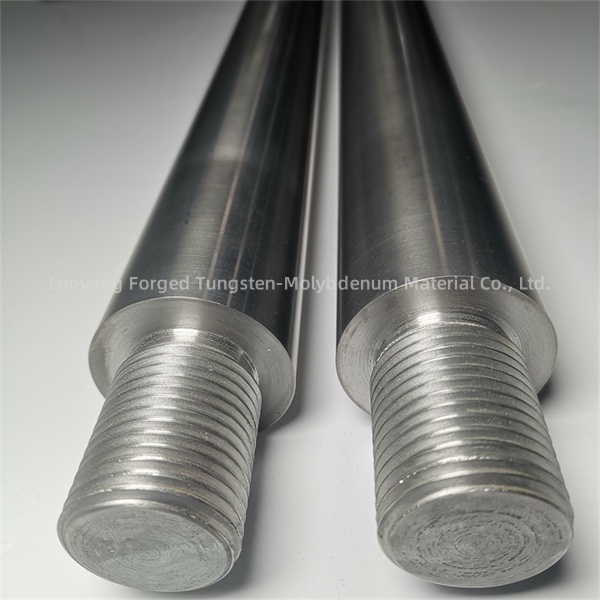

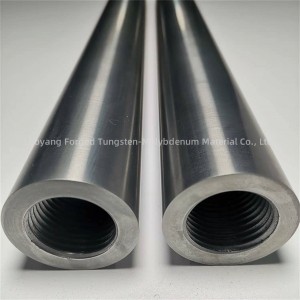

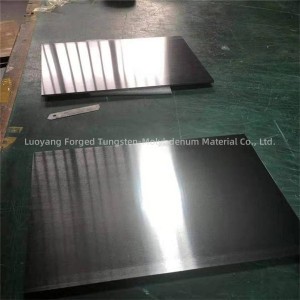

W1 pure tungsten electrode bar for furnace

Tungsten electrode rod is a common electrode rod with characteristics such as high melting point, high density, high hardness, and low thermal expansion coefficient. Therefore, it is widely used in electrode work in high-temperature areas. Among them, tungsten oxide electrode rods are widely used in process fields such as argon arc welding and plasma cutting due to their long service life and good oxidation resistance.

| Dimensions | As your drawings |

| Place of Origin | Luoyang, Henan |

| Brand Name | FGD |

| Application | Industry |

| Surface | Polished |

| Purity | 99.95% |

| Material | Pure tungsten |

| Density | 19.3g/cm3 |

| melting point | 3400℃ |

| Usage environment | Vacuum environment |

| Usage temperature | 1600-2500℃ |

| Main components |

W>99.95% |

|

Impurity content≤ |

|

|

Pb |

0.0005 |

|

Fe |

0.0020 |

|

S |

0.0050 |

|

P |

0.0005 |

|

C |

0.01 |

|

Cr |

0.0010 |

|

Al |

0.0015 |

|

Cu |

0.0015 |

|

K |

0.0080 |

|

N |

0.003 |

|

Sn |

0.0015 |

|

Si |

0.0020 |

|

Ca |

0.0015 |

|

Na |

0.0020 |

|

O |

0.008 |

|

Ti |

0.0010 |

|

Mg |

0.0010 |

1. Our factory is located in Luoyang City, Henan Province. Luoyang is a production area for tungsten and molybdenum mines, so we have absolute advantages in quality and price;

2. Our company has technical personnel with over 15 years of experience, and we provide targeted solutions and suggestions for each customer's needs.

3. All of our products undergo strict quality inspection before being exported.

4. If you receive defective goods, you can contact us for a refund.

1. Mixing of ingredients

2. press forming

3. Sintering infiltration

4. cold-work

Aerospace, metallurgy, machinery and other industries: Tungsten electrode rods are also widely used in aerospace, metallurgy, machinery and other industries for manufacturing high-temperature resistant materials, electrical alloys, electrical machining electrodes, microelectronic materials, etc. These applications require materials with extremely high precision and reliability.

In addition, tungsten electrode rods are also used for manufacturing filaments and high-speed cutting of alloy steel, superhard molds, and for the manufacture of optical and chemical instruments. In the military field, tungsten electrode rods also have important applications.

This is mainly due to excessive current, exceeding the allowable current range of the tungsten electrode; Improper selection of tungsten electrodes, such as mismatched diameter or model; Improper grinding of tungsten electrodes leads to melting; And issues with welding techniques, such as frequent contact and ignition between tungsten tips and base materials, leading to accelerated wear and tear.

1. Dirt or oxidation: The conductivity of tungsten decreases as the degree of oxidation on its surface increases. If the surface area of the tungsten rod accumulates a lot of dirt or is not cleaned for a long time, it will affect its conductivity.

2. Low purity: If there are other impurity metals in the material of the tungsten rod, they may limit the flow of current and cause the tungsten rod to be non-conductive.

3. Uneven sintering: During the manufacturing process of tungsten rods, sintering is required. If the sintering is uneven, adverse reactions may occur on the surface, which can also lead to a decrease in the conductivity of the tungsten rod.