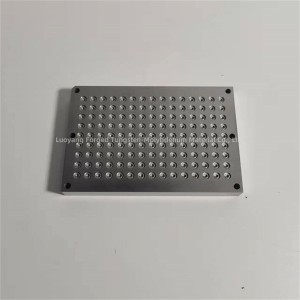

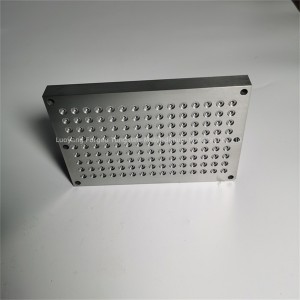

Tungsten wire drawing plate round hole punching

Tungsten carbide drawing plate is a tool used to reduce the diameter of wire or rod during the drawing process. It is made from tungsten carbide, a hard and wear-resistant material known for its durability and ability to withstand the high pressure and force involved in the drawing process.

The pull plate consists of a flat, hardened metal plate with a series of holes of decreasing diameter drilled into it. The wire or rod is pulled through the holes, and as it passes through each progressively smaller hole, its diameter decreases while also improving its surface finish.

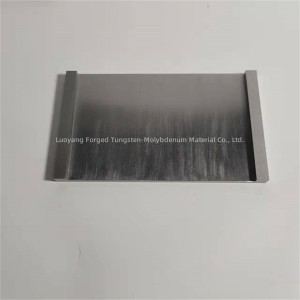

Brushed tungsten carbide sheets are commonly used in industries such as jewelry manufacturing, metalworking, and wire production, where precise diameter control and surface finish are critical to the quality of the final wire or rod product.

The natural color of tungsten carbide is dark gray or gunmetal gray. This color is characteristic of the material and is often used in its original form for a variety of applications. When polished, tungsten carbide can also take on a metallic luster, enhancing its visual appeal.

Tungsten carbide is relatively expensive due to several factors:

1. Raw material cost: Tungsten is one of the main components of tungsten carbide and a rare precious metal. Its scarcity and the challenges associated with its extraction contribute to the high cost of tungsten carbide.

2. Manufacturing process: The production of tungsten carbide involves complex manufacturing processes, including powder metallurgy and high-temperature and high-pressure sintering. These processes require specialized equipment and expertise, adding to the overall cost.

3. Characteristics and performance: Tungsten carbide is valued for its excellent hardness, wear resistance and high temperature performance. Its unique properties make it the material of choice for demanding applications, which results in its higher cost than other materials.

4. Tools and equipment: Due to the extremely high hardness of tungsten carbide, its processing and forming require specialized tools and equipment. The cost of maintaining and operating such equipment adds to the overall expense of using tungsten carbide.

These factors combine to result in the relatively high cost of tungsten carbide, making it an investment for applications that require its specific performance and performance characteristics.

Wechat:15138768150

WhatsApp: +86 15838517324

E-mail : jiajia@forgedmoly.com