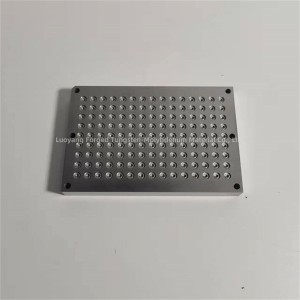

tungsten alloy rod for die casting mould produce

Die casting molds, also known as punch dies, are typically made from high-quality tool steel. Specific types of tool steel used for die casting molds include:

1. H13 tool steel: H13 is a hot work tool steel that is commonly used in die-casting molds due to its excellent combination of high toughness, heat resistance and wear resistance. It can withstand the high temperatures and thermal cycles associated with the die-casting process.

2. P20 Tool Steel: P20 is a general purpose mold steel typically used in low-volume die casting applications. It has good machinability, polishability and dimensional stability.

3. D2 tool steel: D2 is a high-carbon, high-chromium tool steel used for die-casting molds that require high wear resistance and good toughness.

These tool steels are selected for die casting molds because they can withstand the high pressures, temperatures and repeated cycles of the die casting process while maintaining dimensional stability and wear resistance. Additionally, they can be machined and polished to create the complex shapes and fine surface finishes required for die casting molds.

Tungsten is a pure metal, not an alloy. It is a refractory metal with the highest melting point of all metals, making it extremely valuable in high temperature applications. Tungsten is known for its exceptional hardness, high density, and resistance to wear and corrosion.

Although tungsten itself is a pure metal, it is often used as an alloying element in the production of tungsten alloys, such as tungsten superalloys, which are made by combining tungsten with other metals to obtain specific properties.

Tungsten is not commonly used as a die casting material because its high melting point and other properties make it challenging to use traditional die casting methods. Tungsten has an extremely high melting point of 3422°C (6192°F), which is significantly higher than other commonly used die casting metals such as aluminum, zinc and magnesium. This high melting point makes using tungsten in traditional die casting processes difficult and impractical.

Instead, tungsten is more commonly used in applications where its high melting point, hardness, and other unique properties are advantageous, such as high-temperature furnace components, electrical contacts, aerospace components, and as an alloying element in materials such as tungsten carbide.

Wechat:15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com