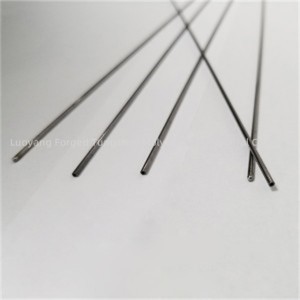

lithupa tsa tungsten tse hloekileng tse nang le bokaholimo bo bentšitsoeng

Tlhahiso ea li-tungsten tse entsoeng ka holim'a metsi le lithupa li kenyelletsa mehato e 'maloa ea bohlokoa, ho kenyelletsa le tlhahiso, ho theha le ho phekola holim'a thepa ea tungsten. Lintlha tse latelang ke kakaretso ea mekhoa ea tlhahiso ea li-tungsten tubes le li-rods tse entsoeng ka holim'a metsi:

1. Tlhahiso ea phofo ea Tungsten: Mokhoa ona o qala ho hlahisa phofo ea tungsten ka ho fokotsa hydrogen ea tungsten oxide kapa ammonium paratungstate. Bohloeki le boholo ba likaroloana tsa phofo ea tungsten ke lintlha tsa bohlokoa ho khethollang boleng ba sehlahisoa sa ho qetela.

2. Compaction le sintering: Sebelisa mochine oa khatiso oa hydraulic kapa mekhoa e meng ea ho kopanya ho hatella phofo ea tungsten ka sebopeho se batlang. Joale tungsten e momahaneng e tšeloa ka sebōping sa mocheso o phahameng oa mocheso, e kopanya likaroloana ho etsa mohaho o tiileng oa tungsten.

3. Shaping: The sintered tungsten e tsoela pele ho sebetsoa ka extrusion, rolling kapa ho taka ho fumana sebopeho se hlokahalang le boholo ba li-tubes le lithupa.

4. Ho sebetsa le ho bentša: Li-tungsten tse entsoeng le lithupa li entsoe ka mochine ho finyella boholo bo hlokahalang le ho qeta holimo. Sena se ka kenyelletsa ho reteleha, ho sila le ho bentša ho etsa sebaka se boreleli le se bentšitsoeng.

5. Taolo ea Boleng: Ho pholletsa le ts'ebetso eohle ea tlhahiso, mehato ea ho laola boleng e kenngoa ts'ebetsong ho netefatsa hore thepa e finyella bohloeki, boholo le litlhoko tsa ho qetela holim'a metsi.

Ke habohlokoa ho hlokomela hore ho hlahisa li-tungsten tubes le lithupa tse nang le libaka tse bentšitsoeng ho hloka tsebo ea ho sebetsana le tungsten hobane ke thepa e thata le e brittle. Ntle le moo, lits'ebetso tsa machining le polishing li bohlokoa ho fihlela pheletso e hlokahalang ea bokaholimo le ho nepahala ha boholo.

Mekhoa e ikhethileng ea tlhahiso e ka fapana ho latela bokhoni ba moetsi le litlhoko tsa ho qetela tsa sehlahisoa. Haeba u na le lipotso tse tobileng mabapi le mekhoa ea tlhahiso ea li-tungsten holim'a li-tungsten le lithupa, kapa u hloka lintlha tse ling, ka kopo ikutloe u lokolohile ho botsa!

Lithapo tsa Tungsten le lithupa tse nang le bokaholimo bo bentšitsoeng li sebelisoa lits'ebetsong tse fapaneng tsa indasteri ka lebaka la thepa e ikhethang ea tungsten. Mona ke lisebelisoa tse ling tse tloaelehileng bakeng sa li-tungsten tubes le lithupa tse nang le bokaholimo bo bentšitsoeng:

1. Lisebelisoa tsa ho futhumatsa: Lithupa tsa Tungsten li sebelisoa e le lisebelisoa tse futhumatsang ka har'a libopi tsa mocheso o phahameng, hammoho le lits'ebetsong tse kang vacuum evaporation le sputtering liindasteri tsa semiconductor le tsa elektronike.

2. Sepakapaka le Tšireletso: Li-tungsten tubes le lithupa li sebelisoa sebakeng sa sefofane le lits'ebetsong tsa ts'ireletso, ho kopanyelletsa le likarolo tsa limisaele, likarolo tsa enjene ea mocheso o phahameng, le li-counterweights ka lebaka la ho teteana ho phahameng le matla a tungsten.

3. Indasteri ea Khalase: Lithapo tsa Tungsten li sebelisoa indastering ea likhalase bakeng sa lits'ebetso tse kang li-electrode tse qhibilihang ka khalase le meaho ea tšehetso ka lebaka la sebaka se phahameng sa ho qhibiliha sa tungsten le ho hanyetsa likhalase tse qhibilihisitsoeng.

4. Lisebelisoa tsa Bongaka: Lithupa tsa Tungsten li sebelisoa lisebelisoa tsa bongaka tse kang li-tubes tsa X-ray le tšireletso ea mahlaseli ka lebaka la matla a tungsten a ho monya mahlaseli le ho lumellana ha eona le biocompatibility.

5. Motlakase oa Ts'ebetso ea Motlakase (EDM): Lithupa tsa Tungsten li sebelisoa e le li-electrode ka mochine oa ho ntša motlakase ka lebaka la boemo ba tsona bo phahameng ba ho qhibiliha le ho apara ho hanyetsa.

6. Likarolo tsa Sebōpi sa Mocheso o Phahameng oa Mocheso: Li-tubes le lithupa tsa Tungsten li sebelisoa lits'ebetsong tsa sebōpi se nang le mocheso o phahameng oa mocheso, ho kenyelletsa le lithebe tsa mocheso, li-crucibles le li-thermocouple sheaths ka lebaka la boemo bo phahameng ba ho qhibiliha ba tungsten le conductivity ea mocheso.

Bokaholimo bo bentšitsoeng ba lithupa tsa tungsten le li-tubes li ka fana ka pheletso e ntlafalitsoeng ea bokaholimo, ho hanyetsa kutu e matlafalitsoeng, le ts'ebetso e ntle lits'ebetsong tse ling. Tšebeliso e khethehileng ea mabala a tungsten a bentšitsoeng a ka fapana ho itšetlehile ka litlhoko tsa kopo le indasteri.

Haeba u na le lipotso tse tobileng mabapi le tšebeliso ea li-tungsten tubes le lithupa tse nang le libaka tse bentšitsoeng ts'ebetsong e itseng, ikutloe u lokolohile ho botsa lintlha tse ling!

| Lebitso la Sehlahiswa | lithupa tsa tungsten tse hloekileng tse nang le bokaholimo bo bentšitsoeng |

| Lintho tse bonahalang | W |

| Tlhaloso | Customized |

| Bokaholimo | Letlalo le letšo, alkaline e hlatsoitsoe, e bentšitsoe. |

| Theknoloji | Sintering process, machining |

| Meltng point | 3400 ℃ |

| Botenya | 19.3g/cm3 |

Wechat: 15138768150

WhatsApp: +86 15138745597