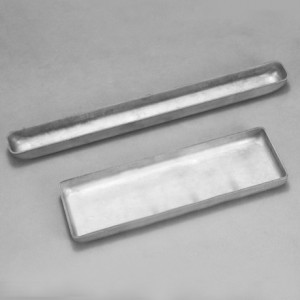

Li-screw tsa Tantalum le li-fasteners tsa linate tsa tantalum

Ts'ebetso ea tlhahiso ea liboutu le linate tsa tantalum e latela ka tieo litekanyetso tsa boleng bo holimo ho netefatsa ho tšoarella le ho ts'epahala ha lihlahisoa. Ba ka mamella mocheso o phahameng haholo le likhatello, 'me ba boloka ts'ebetso e tsitsitseng esita le maemong a feteletseng. Ka hona, liboutu tsa tantalum le linate li sebelisoa hangata lits'ebetsong tse hlokang chelete e ngata indastering le saenseng, joalo ka sepakapaka, lisebelisoa tsa nyutlelie, le ho etsoa ha lisebelisoa tsa bongaka tsa maemo a holimo. "

| Litekanyo | Joalo ka tlhoko ea hau |

| Sebaka sa Tšimoloho | Luoyang, Henan |

| Lebitso la Brand | FGD |

| Kopo | Indasteri, semiconductor |

| Bohloeki | 99.95% |

| Sebaka se qhibilihang | 2996 ℃ |

| Botenya | 16.65g/cm3 |

| Ho thatafala | HV250 |

| λ/nm | f | W | F | S* | CL | G |

| 271.5 | 0.055 | 0.2 | NA | 30 | 1.0 | |

| 260.9(D) | 0.2 | NA | 23 | 2.1 | ||

| 265.7 | 0.2 | NA | 2.5 | |||

| 293.4 | 0.2 | NA | 2.5 | |||

| 255.9 | 0.2 | NA | 2.5 | |||

| 264.8 | 0.2 | NA | x | |||

| 265.3 | 0.2 | NA | 2.7 | |||

| 269.8 | 0.2 | NA | 2.7 | |||

| 275.8 | 0.2 | NA | 3.1 | |||

| 277.6 | 0.2 | NA | 58 |

1. Feme ea rona e Motseng oa Luoyang, Profinseng ea Henan. Luoyang ke sebaka sa tlhahiso bakeng sa merafo ea tungsten le molybdenum, kahoo re na le melemo e feletseng ka boleng le theko;

2. Khampani ea rona e na le basebetsi ba theknoloji ba nang le phihlelo ea lilemo tse fetang 15, 'me re fana ka litharollo le litlhahiso tse lebisitsoeng bakeng sa litlhoko tsa moreki ka mong.

3. Lihlahisoa tsohle tsa rona li hlahlojoa ka thata boleng pele li romeloa linaheng tse ling.

4. Haeba o fumana thepa e nang le bokooa, o ka ikopanya le rona bakeng sa puseletso.

1. ho lokisetsa thepa e tala

(Khetha lisebelisoa tse loketseng tsa terata kapa boto ho netefatsa hore thepa e fihlela litlhoko tse tloaelehileng.)

2. Ts'ebetso ea mohala / ho hatakela

(Tsela e sebetsoa hore e be likheo tsa screw ka mechini e batang ea hlooho; tšepe ea lakane e phunyeletsoa likheong tsa linate ka mochine oa khatiso oa punch. Mohato ona ke ho theha sebopeho sa motheo sa bolt le nut).

3. phekolo ea mocheso

(Mocheso o tšoara sekheo, joalo ka ho tima, ho halefa, joalo-joalo, ho matlafatsa ho thatafala le ho tiea, ho netefatsa thepa ea mochini oa fastener)

4. Ho roala khoele / meno a tlanya

(Likheo tsa screw li entsoe ka mochini o roalang; Sekheo sa linate se sebetsoa ka likhoele tse kahare mochining oa ho tlanya)

5.Kalafo ea Bokaholimo

(Liphekolo tsa holim'a metsi tse kang electroplating, oxidation, phosphating, joalo-joalo li etsoa ho latela litlhoko tsa ho eketsa ho hanyetsa kutu le botle bo botle.

6. ho lemoha

(Sebelisa li-gauge, lisebelisoa tsa optical, joalo-joalo ho hlahloba ka botlalo lihlahisoa tse felileng bakeng sa boholo, ho nepahala ha khoele, bofokoli ba bokaholimo, joalo-joalo, ho netefatsa boleng)

7. Screening le Packaging

(Tlosa lihlahisoa tse sa lumellaneng ka mochini oa skrini o thothomelang, o li arole ho ea ka litlhaloso, ebe u li kenya ka bohona kapa ka letsoho)

8. taolo ya boleng

(Sampling bakeng sa tlhahlobo ea ts'ebetso ea mochini, joalo ka tlhahlobo ea ho tiea, tlhahlobo ea torque, joalo-joalo, ho netefatsa hore sehlahisoa se kopana le maemo a indasteri le a bareki)

Lipehelo tsa Molybdenum li sebelisoa hangata ho li-tubes tsa X-ray bakeng sa litšoantšo tsa bongaka, tlhahlobo ea indasteri le lipatlisiso tsa mahlale. Likopo tsa sepheo sa molybdenum ke tsa ho hlahisa li-X-ray tse matla haholo bakeng sa litšoantšo tsa tlhahlobo, joalo ka liskena tsa computed tomography (CT) le radiography.

Liphoofolo tsa Molybdenum li ratoa bakeng sa ntlha ea tsona e phahameng ea ho qhibiliha, e leng se li lumellang ho mamella mocheso o phahameng o hlahisoang nakong ea tlhahiso ea X-ray. Li boetse li na le conductivity e ntle ea mocheso, e thusang ho senya mocheso le ho lelefatsa bophelo ba X-ray tube.

Ntle le litšoantšo tsa bongaka, lipehelo tsa molybdenum li sebelisetsoa tlhahlobo e sa senyeheng lits'ebetsong tsa indasteri, joalo ka ho hlahloba li-welds, liphaephe le likarolo tsa sefofane. Li boetse li sebelisoa litsing tsa lipatlisiso tse sebelisang spectroscopy ea X-ray fluorescence (XRF) bakeng sa tlhahlobo ea thepa le boitsebahatso ba mantlha.

Li-screw tse bapisang le linate li kenyelletsa ho netefatsa hore likhoele tsa li-screw le linate lia lumellana. Mehato e akaretsang ea ho kopanya li-screw le linate ke tsena:

1. Fumana boholo ba screw: Lekanya bophara le bolelele ba screw ho fumana boholo ba eona. Li-screw tsa boholo bo tloaelehileng li khethoa ho sebelisoa palo e lateloang ke karoloana, joalo ka #8-32 kapa #10-24.

2. Lemoha mefuta ea likhoele: Likhoele le linate li ka ba le mefuta e fapaneng ea likhoele, tse kang likhoele tse mahoashe kapa likhoele tse ntle. Ke habohlokoa hore mofuta oa khoele oa screw o lumellane le linate tse lumellanang.

3. Lekola sekontiri sa khoele: Lekhalo la khoele le bolela sebaka se pakeng tsa likhoele tse bapileng holim'a screw kapa nut. Etsa bonnete ba hore likurufu le linate li na le khoele e ts'oanang ho netefatsa hore li kopane hantle.

4. Nahana ka lisebelisoa le matla: Khetha likurufu le linate tse entsoeng ka thepa e lumellanang le matla a tšoanang ho netefatsa hore li ka mamella ts'ebeliso e reriloeng.

5. Lekola ho lekana: Pele ho khetho ea ho qetela, leka li-screws le linate ho netefatsa hore li kopane hantle le ka mokhoa o sireletsehileng.

Ka ho latela mehato e ka tlase, o ka bapisa li-screw le linate ka nepo le ts'ebeliso ea hau e ikhethileng.

Ha u nahana ka moralo oa likhoele bakeng sa liboutu le linate tsa tantalum, ho na le lintlha tse 'maloa tsa bohlokoa tse lokelang ho hlokomeloa ka lebaka la thepa e ikhethang ea tantalum:

1. Tšebelisano ea Lintho: Tantalum ke tšepe e thibelang ho bola, kahoo ke habohlokoa ho etsa bonnete ba hore lisebelisoa tse sebelisoang bakeng sa linate le liboutu li boetse li lumellana le tantalum. Ho sebelisa lisebelisoa tse sa lumellaneng le tantalum ho ka baka kutu ea galvanic le ho senya botšepehi ba lenonyeletso.

2. Lubrication ea khoele: Tantalum e na le tšekamelo ea ho apara, e leng mokhoa oa ho khomarela thepa le ho fetisa pakeng tsa libaka tse thellang. Ho fokotsa bothata bona, ho lokela ho nahanoa ka lubrication e nepahetseng ha ho etsoa liboutu le linate tsa tantalum ho thibela ho roala le ho netefatsa kopano e boreleli le ho qhaqhoa.

3. Matla a khoele: Tantalum ke tšepe e batlang e le bonolo, kahoo matla a thepa a lokela ho nahanoa ha ho etsoa likhoele. Ho bohlokoa ho etsa bonnete ba hore foromo ea khoele le boitlamo li fana ka matla a lekaneng bakeng sa ts'ebeliso e reriloeng ha u ntse u qoba khatello ea maikutlo e feteletseng.

4. Foromo ea khoele: Foromo ea khoele, ebang ke metric, junifomo, kapa litekanyetso tse ling, e lokela ho khethoa ka hloko ho netefatsa hore e lumellana le likarolo tsa ho nyalana le ho finyella litlhoko tse khethehileng tsa kopo.

5. Qetello ea Bokahohle: Li-bolts tsa Tantalum le linate li lokela ho ba le sebaka se boreleli le se ts'oanang ho fokotsa monyetla oa ho apara le ho tiisa ho tiisa ho nepahetseng ha motsoako o pepesehetse metsi kapa likhase.

Ka ho rarolla mathata ana ka moralo oa tantalum bolt le nut thread, o ka etsa bonnete ba ho ts'epahala le ts'ebetso ea lits'ebetso tsa hau tsa ho tiisa lits'ebetsong tsa tantalum.