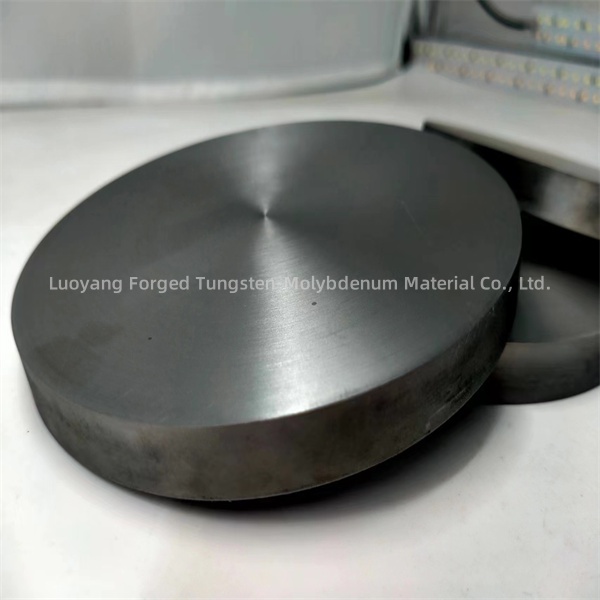

Tlhōlo e phahameng ea titanium sputtering targets for vacuum coating

Liphehelo tsa sputter ke lisebelisoa tsa boleng bo phahameng tse sebelisoang lits'ebetsong tsa 'mele oa ho kenya mouoane (PVD), haholo-holo theknoloji ea sputtering. Lisebelisoa tsena li sebelisetsoa ho etsa lifilimi tse tšesaane ho li-substrates liindastering tse fapaneng, ho kenyelletsa le tlhahiso ea semiconductor, li-optical coatings, le ho beha lifilimi tse tšesaane bakeng sa lisebelisoa tsa elektroniki.

Lisebelisoa tse shebiloeng tsa sputter li ka etsoa ho tsoa linthong tse fapaneng le metsoako, ho kenyeletsoa litšepe, lialloys, oxides le nitride. Khetho ea thepa ea sepheo sa sputter e itšetlehile ka thepa e khethehileng e hlokahalang bakeng sa ho roala filimi e tšesaane, joalo ka conductivity ea motlakase, thepa ea optical, thata le lik'hemik'hale.

Lipheo tse tloaelehileng tsa sputtering li kenyelletsa litšepe tse kang titanium, aluminium le koporo, hammoho le metsoako e kang indium tin oxide (ITO) le li-oxide tse fapaneng tsa tšepe. Ho khetha thepa e nepahetseng ea sputtering ho bohlokoa ho fihlela litšoaneleho tse lakatsehang le ts'ebetso ea likhoele tse tšesaane tsa filimi.

Lipheo tsa sputtering li tla ka boholo bo fapaneng ho latela litlhoko tse khethehileng tsa ts'ebetso ea ho beha filimi e tšesaane le lisebelisoa tsa sputtering. Boholo ba sepheo sa sputtering se ka tloha ho lisenthimithara tse 'maloa ho isa ho mashome a lisenthimithara ka bophara,' me botenya le bona bo ka fapana.

Boholo ba sepheo sa ho sputtering bo khethoa ke lintlha tse kang boholo ba substrate e lokelang ho koaheloa, tlhophiso ea tsamaiso ea sputtering, le tekanyo e lakatsehang ea ho beha le ho tšoana. Ho phaella moo, boholo ba sepheo sa sputtering se ka 'na sa angoa ke litlhoko tse khethehileng tsa kopo ea filimi e tšesaane, e kang sebaka se lokelang ho koaheloa le mekhoa ea kakaretso ea ts'ebetso.

Qetellong, boholo ba sepheo sa sputter se khethiloe ho netefatsa hore filimi e kenngoa ka mokhoa o nepahetseng le o ts'oanang holim'a substrate, ho finyella litlhoko tse khethehileng tsa mokhoa o mosesaane oa ho roala filimi ho etsoa ha semiconductor, liaparo tsa optical le lisebelisoa tse ling tse amanang le tsona.

Ho na le litsela tse 'maloa tsa ho eketsa sekhahla sa ho sputtering ka mokhoa oa ho sputtering:

1. Matlafatso ea Matla le Khatello: Ho fetola matla le likhatello tsa khatello tsamaisong ea sputtering ho ka ama sekhahla sa sputtering. Ho eketsa matla le ho ntlafatsa maemo a khatello ho ka matlafatsa sekhahla sa ho sputtering, se lebisang ho beheng filimi e tšesaane ka potlako.

2. Thepa e Lebeletsoeng le Geometry: Ho sebelisa liphofu tsa sputtering tse nang le sebopeho se ntlafalitsoeng sa thepa le geometry ho ka ntlafatsa sekhahla sa sputtering. Lipheo tsa boleng bo holimo, tse hlophisitsoeng hantle li ka ntlafatsa ts'ebetso ea sputtering 'me tsa lebisa ho litheko tse phahameng tsa deposition.

3. Boitokisetso ba Sebaka se Lebeletsoeng: Ho hloekisoa hantle le ho lokisa sebaka seo ho hlajoang ho sona ho ka tlatsetsa ho eketseha ha likhahla. Ho etsa bonnete ba hore sebaka seo ho shebiloeng ho sona ha se na litšila le li-oxide ho ka ntlafatsa ts'ebetso ea sputtering.

4. Mocheso oa Substrate: Ho laola mocheso oa substrate ho ka ama sekhahla sa sputtering. Maemong a mang, ho phahamisa mocheso oa substrate ka har'a mefuta e itseng ho ka lebisa ho eketseha ha litekanyetso tsa sputtering le boleng bo ntlafetseng ba filimi.

5. Phallo ea Khase le Sebopeho: Ho ntlafatsa phallo ea khase le ho hlophisoa ka phaposing ea sputtering ho ka ama sekhahla sa ho fafatsa. Ho fetola sekhahla sa phallo ea khase le ho sebelisa metsoako e nepahetseng ea khase ea sputtering ho ka ntlafatsa ts'ebetso ea ts'ebetso ea sputtering.

Ka ho hlahloba lintlha tsena ka hloko le ho ntlafatsa maemo a ts'ebetso ea sputtering, hoa khoneha ho eketsa sekhahla sa sputtering le ho ntlafatsa katleho ea kakaretso ea ho kenya filimi e tšesaane lits'ebetsong tsa sputtering.

Wechat: 15138768150

WhatsApp: +86 15838517324

E-mail : jiajia@forgedmoly.com