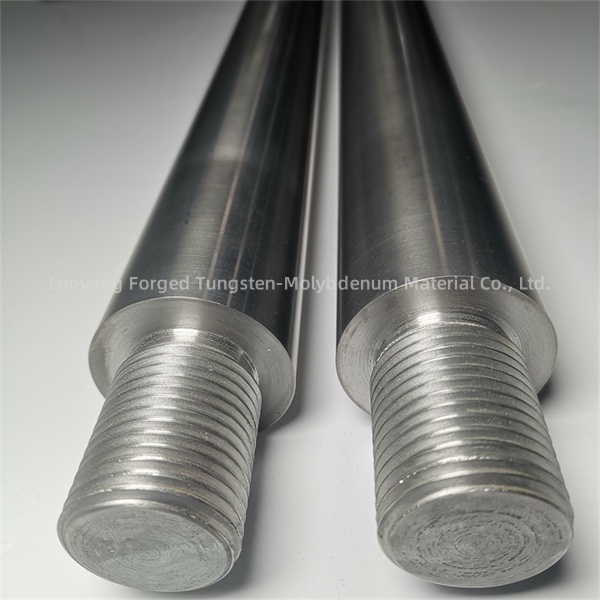

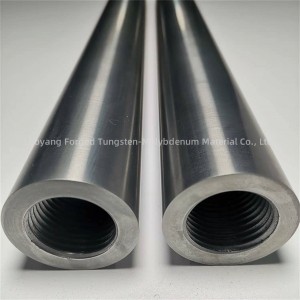

W1 yakachena tungsten electrode bar ye welding

Tungsten electrode tsvimbo yakajairika electrode tsvimbo ine hunhu hwakaita senge yakakwira melting point, high density, kuomarara kwakanyanya, uye yakaderera thermal yekuwedzera coefficient. Nokudaro, inoshandiswa zvakanyanya mubasa re electrode munzvimbo dzakakwirira-kupisa. Pakati pavo, tungsten oxide electrode tsvimbo dzinoshandiswa zvakanyanya mundima dzekuita senge argon arc welding uye plasma yekucheka nekuda kwehupenyu hwavo hwesevhisi uye yakanaka oxidation kuramba.

| Dimensions | Semifananidzo yako |

| Nzvimbo Yekwakabva | Luoyang, Henan |

| Brand Name | FGD |

| Application | Indasitiri |

| Surface | Yakanatswa |

| Kuchena | 99.95% |

| Material | Tungsten yakachena |

| Density | 19.3g/cm3 |

| melting point | 3400 ℃ |

| Nzvimbo yekushandisa | Vacuum environment |

| Kushandisa tembiricha | 1600-2500 ℃ |

| Main components | W>99.95% |

| Kusachena kwemukati≤ | |

| Pb | 0.0005 |

| Fe | 0.0020 |

| S | 0.0050 |

| P | 0.0005 |

| C | 0.01 |

| Cr | 0.0010 |

| Al | 0.0015 |

| Cu | 0.0015 |

| K | 0.0080 |

| N | 0.003 |

| Sn | 0.0015 |

| Si | 0.0020 |

| Ca | 0.0015 |

| Na | 0.0020 |

| O | 0.008 |

| Ti | 0.0010 |

| Mg | 0.0010 |

1. Fekitari yedu iri muLuoyang City, Henan Province. Luoyang inzvimbo yekugadzira ye tungsten uye molybdenum migodhi, saka isu tine mabhenefiti akakwana mumhando uye mutengo;

2. Kambani yedu ine vashandi vehunyanzvi vane makore anopfuura gumi nemashanu echiitiko, uye isu tinopa zvakanangwa mhinduro uye mazano kune ega ega zvinodiwa nemutengi.

3. Zvose zvezvigadzirwa zvedu zvinoongororwa zvakasimba zvehutano zvisati zvatengeswa kunze kwenyika.

4. Kana ukagamuchira zvinhu zvisina kukwana, unogona kutibata nesu kuti tidzorere mari.

1. Kusanganiswa kwezvinhu

2. kudhinda kuumba

3. Sintering infiltration

4. kutonhora-basa

Aerospace, metallurgy, machinery and other industry kunyatsojeka kwepamusoro uye kuvimbika.

Mukuwedzera, tungsten electrode tsvimbo inoshandiswawo kugadzira filaments uye yakakwirira-yekukurumidza kucheka kwesimbi yealloy, superhard molds, uye nekugadzira michina yemaziso nemakemikari. Mumunda wemauto, tungsten electrode tsvimbo zvakare ine yakakosha maapplication.

Izvi zvinonyanya kukonzerwa nekunyanyisa ikozvino, kudarika inobvumirwa ikozvino yakasiyana-siyana ye tungsten electrode; Kusarudzwa kusina kunaka kwe tungsten electrodes, yakadai sedhayamita isina kufananidzwa kana modhi; Kukuya kusina kunaka kwe tungsten electrodes kunotungamirira mukunyunguduka; Uye nyaya nehunyanzvi hwekugadzira welding, senge kugara uchisangana uye kudzima pakati petungsten matipi uye base zvinhu, zvinotungamira kukurumidza kupfeka uye kubvaruka.

1. Tsvina kana oxidation: Iko conductivity ye tungsten inoderera sezvo dhigirii ye oxidation pamusoro payo inowedzera. Kana iyo nzvimbo yepamusoro ye tungsten tsvimbo inounganidza yakawanda tsvina kana isina kucheneswa kwenguva yakareba, inokanganisa conductivity yayo.

2. Kuchena kwakaderera: Kana pane mamwe masimbi asina kuchena muzvinhu zvetungsten tsvimbo, inogona kuderedza kuyerera kwezvino uye kuita kuti tungsten tsvimbo ive isina-conductive.

3. Kusaita sintering: Munguva yekugadzira tungsten tsvimbo, sintering inodiwa. Kana iyo sintering isina kuenzana, kukanganisa kwakashata kunogona kuitika pamusoro, izvo zvinogonawo kutungamirira kuderera kwekutengesa kwetambo ye tungsten.