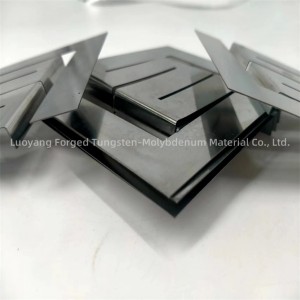

molybdenum sheet molybdenum ndiro molybdenum gasket

Kugadzirwa kwe molybdenum mashizha uye gaskets kunowanzobatanidza anotevera matanho anokosha:

1. Molybdenum powder production: Iyi nzira inotanga kubudisa molybdenum powder kuburikidza nehydrogen kuderedzwa kwe molybdenum oxide uye mamwe maitiro. Izvi zvinoguma nekuumbwa kwepamusoro kuchena molybdenum powder.

2. Powder compaction: Iyo molybdenum poda inobva yatsikirirwa kuva yakasimba fomu uchishandisa nzira dzakadai sekutonhora kunotonhora kana isostatic pressing. Iyi nhanho inobatsira kuumba muviri wakasvibira nechimiro chinodiwa uye saizi.

3. Sintering: The green body is sintered at high temperature in a controlled atmosphere, kazhinji muvacuum kana hydrogen environment. Sintering inobatsira kusunga molybdenum zvidimbu pamwechete, kugadzira yakasimba uye yakakora molybdenum sheet kana gasket zvinhu.

4. Hot rolling: Kuti ibudise mahwendefa emolybdenum, sintered molybdenum zvinhu inopisa yakakungurutswa kuti iwane kukora kunodiwa uye kupera kwepamusoro. Maitiro acho anosanganisira kudziyisa zvinhu kusvika kune tembiricha yakakwira uye nekuipfuudza nepakati peguyo kuti ideredze ukobvu hwayo uye kuvandudza mashandiro ayo.

5. Machining: Iyo yakakungurutswa molybdenum ndiro inobva yagadzirwa kuti iwane zviyero zvekupedzisira uye kupera kwepamusoro kunodiwa kune chaiyo application. Izvi zvinogona kusanganisira nzira dzakaita sekucheka, kugaya kana kukuya.

6. Kudzora kwehutano: Munguva yese yekugadzira, maitiro ekugadzirisa maitiro anoshandiswa kuti ave nechokwadi chokuti molybdenum plates uye gaskets zvinosangana nezvinodiwa, kusanganisira kurongeka kwedimensional, kunaka kwepamusoro, uye zvinhu zvakadai sesimba uye ductility.

Nekutevera aya matanho ekugadzira, vagadziri vanogona kugadzira emhando yepamusoro molybdenum mahwendefa uye gaskets akakodzera kupisa kwakanyanya uye kumanikidza kushandiswa, zvichipa chisimbiso chakavimbika uye kushanda munzvimbo dzinoda.

Molybdenum mahwendefa uye gaskets ane zvakasiyana-siyana zvekushandisa, kunyanya mumaindasitiri umo tembiricha yepamusoro uye nzvimbo dzekumanikidza dzakajairwa. Mamwe mashandisirwo chaiwo e molybdenum mahwendefa uye gaskets anosanganisira:

1. Chivira chekushisa chepamusoro: Mahwendefa eMolybdenum anoshandiswa sezvinhu zvinopisa, zvidziviriro zvekupisa uye zvigadziro zvekugadzirisa mumoto wekushisa kwepamusoro uye midziyo yekurapa kupisa. Molybdenum's high melting point uye yakanakisa yekupisa conductivity inoita kuti ive yakakodzera kune izvi zvinoshandiswa.

2. Aerospace uye Defence: Molybdenum gaskets inoshandiswa mumhepo uye zvidziviriro zvikumbiro kuti zvipe chisimbiso chakavimbika mukupisa kwepamusoro uye kudzvinyirirwa kwepamusoro, zvakadai semuinjini dzendege, rocket propulsion systems uye mauto ehondo.

3. Kugadzirwa kwemagetsi: Molybdenum plates uye gaskets zvinoshandiswa mumagetsi ekugadzira magetsi, kusanganisira magetsi emagetsi enyukireya, nokuda kwezvikamu zve reactor, high-temperature steam systems, uye zvimwe midziyo inokosha inoda kuiswa chisimbiso kwakavimbika uye kudzivisa kuora.

4. Kugadziriswa kwemakemikari: Molybdenum gaskets inoshandiswa mumakemikari ekugadzirisa zvinhu, zvakadai semagetsi, midziyo uye pombi masisitimu, kupa chisimbiso chinoshanda munzvimbo dzinopisa uye dzepamusoro-tembiricha.

5. Semiconductor kugadzira: Molybdenum mashizha anoshandiswa mukugadzirwa kwezvigadzirwa zve semiconductor uye anoshandiswa se substrates, kupisa kunyura uye zvikamu zvekugadzirwa kwepamusoro-kupisa mukugadzira semiconductor.

Mumashandisirwo aya, mahwendefa emolybdenum uye gaskets zvinopa zvakanakisa kupisa uye zvemichina zvivakwa, pamwe nekuramba corrosion uye tembiricha yepamusoro, zvichiita kuti zvive zvakanakira kushandiswa munzvimbo dzakaomarara dzeindasitiri.

| Product Name | Molybdenum Sheet Molybdenum Gasket |

| Material | Mo1 |

| Tsanangudzo | Customized |

| Surface | Ganda dema, alkali yakashambidzwa, yakakwenenzverwa. |

| Technique | Sintering process, machining |

| Meltng point | 2600 ℃ |

| Density | 10.2g/cm3 |

Wechat:15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com