High kuchena titanium sputtering chinangwa chevacuum coating

Zvinangwa zveSputter zvinhu zvakakwirira-zvakachena zvinoshandiswa mune zvemuviri vapor deposition (PVD) maitiro, kunyanya sputtering tekinoroji. Zvishandiso izvi zvinoshandiswa kugadzira mafirimu matete pane substrates mune akasiyana maindasitiri, anosanganisira semiconductor kugadzira, optical coatings, uye nhete firimu deposition yemidziyo yemagetsi.

Sputter chinangwa chemidziyo inogona kugadzirwa kubva kwakasiyana zvinhu uye makomisheni, anosanganisira simbi, alloys, oxides uye nitrides. Sarudzo ye sputter inotariswa zvinhu zvinoenderana neiyo chaiyo midziyo inodiwa kune yakaonda firimu coating, senge magetsi conductivity, optical properties, kuoma uye makemikari kuramba.

Zvinangwa zvekupopotera zvakajairwa zvinosanganisira simbi dzakadai setitanium, aruminiyamu nemhangura, pamwe nemakomisheni akadai seindium tin oxide (ITO) uye akasiyana simbi oxides. Kusarudza iyo yakakodzera sputtering yakanangwa zvinhu kwakakosha kuti uwane hunhu hunodiwa uye kuita kwemafirimu akaonda.

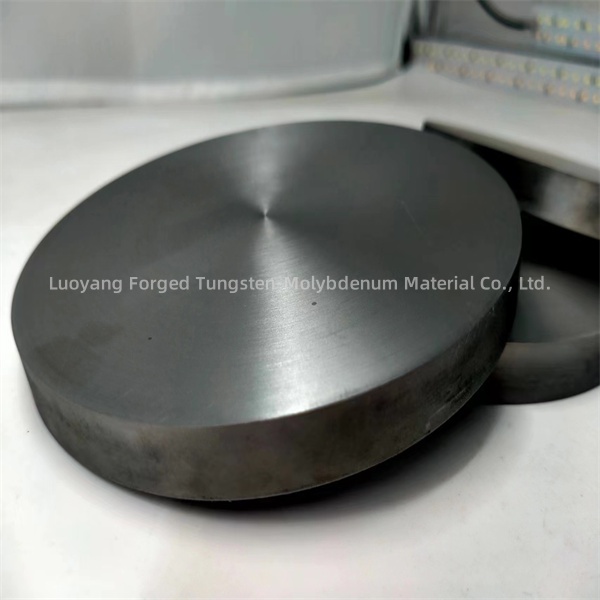

Zvinangwa zveSputtering zvinouya muhukuru hwakasiyana zvichienderana nezvinodiwa zveyakaonda firimu deposition process uye sputtering equipment. Kukura kwechinangwa chekuputira kunogona kubva pamasendimita mashoma kusvika makumi emasendimita mudhayamita, uye ukobvu hunogonawo kusiyana.

Kukura kwechinangwa chekupopotera kunotariswa nezvinhu zvakaita sehukuru hwe substrate ichavharwa, kumisikidzwa kweiyo sputtering system, uye inodiwa deposition rate uye kufanana. Pamusoro pezvo, saizi yeiyo sputtering tarisiro inogona kukanganiswa nezvinodiwa chaizvo zveyakaonda firimu application, senge nzvimbo ichavharwa uye yakazara maitiro paramita.

Pakupedzisira, saizi yechinangwa che sputter inosarudzwa kuti ive nechokwadi chekuisa uye yunifomu yekuiswa kwefirimu pane substrate, kusangana nezvinodiwa chaizvo zveyakaonda firimu yekuputira maitiro mukugadzira semiconductor, optical coatings uye zvimwe zvine chekuita nekushandisa.

Pane nzira dzinoverengeka dzekuwedzera mwero wekupopotera mukuita sputtering:

1. Simba uye Pressure Optimization: Kugadzirisa simba uye kudzvinyirira parameters mu sputtering system inogona kukanganisa sputtering rate. Kuwedzera simba uye optimize kudzvanywa mamiriro anogona kuwedzera sputtering mwero, zvichitungamirira kukurumidza kuiswa kwefirimu rakatetepa.

2. Target Material uye Geometry: Kushandisa sputtering targets with optimized material composition and geometry inogona kuvandudza sputtering rate. Yepamusoro-mhando, yakanyatsogadzirirwa sputtering tarisiro inogona kuwedzera sputtering kunyatsoshanda uye kutungamirira kune yakakwirira deposition mitengo.

3. Target Surface Preparation: Kucheneswa kwakakodzera uye kugadzirisa kweiyo sputtering target surface kunogona kuita kuti kunyura kuwedzere. Kuve nechokwadi chekuti nzvimbo yakanangwa haina tsvina kubva kune zvinosvibisa uye okisidhi inogona kunatsiridza sputtering kushanda zvakanaka.

4. Substrate Temperature: Kudzora tembiricha ye substrate inogona kukanganisa mwero wekupopota. Mune zvimwe zviitiko, kusimudza tembiricha ye substrate mukati meimwe siyana kunogona kukonzera kuwedzera sputtering mitengo uye yakagadziridzwa firimu mhando.

5. Kuyerera kweGasi uye Kuumbwa: Kugadzirisa kuyerera kwegasi uye kuumbwa mukamuri yekuputira kunogona kukanganisa chiyero chekuputika. Kugadzirisa magasi ekuyerera kwemazinga uye kushandisa yakakodzera sputtering gasi musanganiswa kunogona kuwedzera sputtering process performance.

Nekunyatsofunga nezvezvinhu izvi uye nekunatsiridza maparamendi ekuita sputtering, zvinokwanisika kuwedzera mwero wekupopota uye nekuvandudza kugona kwese kweiyo yakaonda firimu deposition mukushandisa sputtering.

Wechat:15138768150

WhatsApp: +86 15838517324

E-mail : jiajia@forgedmoly.com