Quality Inspection for Welding Tantalum Tube - OEM Manufacturer Density Hot Sale Cuw Product 80/20 Tungsten Copper Alloy Tube – Forged Tungsten

Quality Inspection for Welding Tantalum Tube - OEM Manufacturer Density Hot Sale Cuw Product 80/20 Tungsten Copper Alloy Tube – Forged Tungsten Detail:

We support our purchasers with ideal premium quality products and substantial level company. Becoming the specialist manufacturer in this sector, we’ve acquired rich practical working experience in producing and managing for OEM Manufacturer Density Hot Sale Cuw Product 80/20 Tungsten Copper Alloy Tube, We’re keeping durable business associations with much more than 200 wholesalers during the USA, the UK, Germany and Canada. Should you be interested in almost any of our items, you should truly feel no cost to get in touch with us.

We support our purchasers with ideal premium quality products and substantial level company. Becoming the specialist manufacturer in this sector, we’ve acquired rich practical working experience in producing and managing for Tungsten Copper Alloy, Tungsten Copper Alloy Tube, Tungsten Copper Tube, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade solutions in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market.

Chemical composition:

| Main and minor components | Min.content(%) | ASTM B760 |

| W | 99.95 | balance |

| Impurities | Max.values (μg/g) | Max.values (μg/g) |

| Al | 15 | - |

| Cu | 10 | - |

| Cr | 20 | - |

| Fe | 30 | 100 |

| K | 10 | - |

| Ni | 20 | 100 |

| Si | 20 | 100 |

| Mo | 100 | - |

| C | 30 | 100 |

| H | 5 | - |

| N | 5 | 100 |

| O | 20 | 100 |

| Cd | 5 | - |

| Hg | 1 | - |

| Pb | 5 | - |

Diameter and tolerances:

| Diameter (mm) | Tolerance | |||

| Straightened | Forged | Turned | Ground | |

| 0.50-0.99 | - | - | ±0.007 | |

| 1.00-1.99 | - | - | ±0.010 | |

| 2.00-2.99 | ±2.0 % | - | ±0.015 | |

| 3.00-15.9 | - | - | ±0.020 | |

| 16.0-24.9 | - | ±0.30 | ±0.030 | |

| 25.0-34.9 | - | ±0.40 | ±0.050 | |

| 35.0-39.9 | - | ±0.40 | ±0.30 | ±0.060 |

| 40.0-49.9 | - | ±0.40 | ±0.30 | ±0.20 |

| 50.0-90.0 | - | ±1.00 | ±0.40 | - |

Length and straightness:

| Diameter (mm) | Production length (mm) | Stiraightness/Meter (mm) | |

| Cleaned | Ground/turned | ||

| 0.50-10.0 | ≥500 | <2.5 | <2.5 |

| 10.1-50.0 | ≥300 | <2.0 | <1.5 |

| 50.1-90.0 | ≥100 | <2.0 | <1.5 |

Length tolerance:

| Diameter 0.50-30.0 mm | ||||||

| Nominal length (mm) | ≥15 | 15-120 | 120-400 | 400-1000 | 1000-2000 | >2000 |

| Length tolerance(mm) | ±0.2 | ±0.3 | ±0.5 | ±2.0 | ±3.0 | ±4.0 |

| Diameter >30.0 mm | ||||||

| Nominal length (mm) | ≥30 | 30-120 | 120-400 | 400-1000 | 1000-2000 | >2000 |

| Length tolerance(mm) | ±0.5 | ±0.8 | ±1.2 | ±4.0 | ±6.0 | ±8.0 |

Density: ≥19.1g/cm³

Nondestructive testing: For diameters>15.00 mm:100% ultrasonic testing. For diameters of 0.50-50.0mm:Eddy curent tests on rods with ground surface.

| Diameter(mm) | Hardness (HV 10) |

| 0.50-2.99 | — |

| 3.00-9.99 | 420-500 |

| 10.0-29.9 | 420-480 |

| 30.0-49.9 | 380-460 |

| ≥50 | >350 |

Surface condition:

| Diameter (mm) | Surface condition |

| 0.50-90.0 | Chemical cleaned |

| ≥40.0 | Turned Ra ≤3.2μm |

| 0.50-30 | Centerless ground Ra≤1.0μm |

| ≥40.0 | - Centerless ground Ra≤1.2μm |

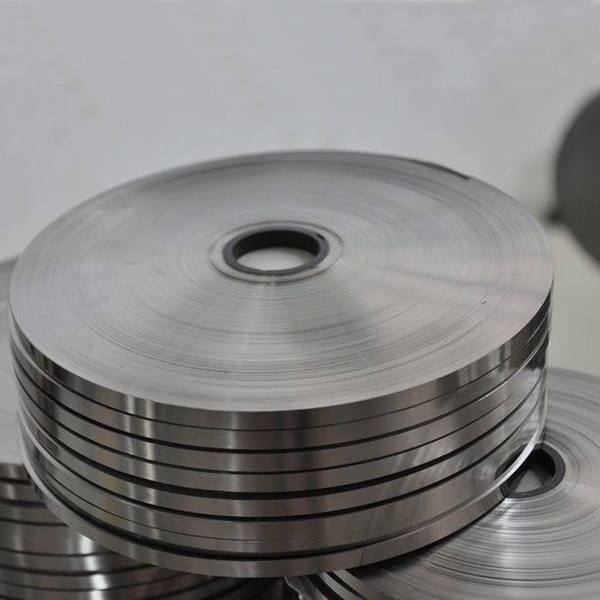

Product detail pictures:

Related Product Guide:

Budget Speech: Full text of Arun Jaitley’s Budget speech | Pure Molybdenum Strip

Augmented Revenues To Be Witnessed By Hot Stamping Foil by 2019 – 2027 | Slivery Color Molybdenum Sheet /Plate

With our loaded working experience and thoughtful products and services, we've got been acknowledged as a reputable supplier for most international buyers for Quality Inspection for Welding Tantalum Tube - OEM Manufacturer Density Hot Sale Cuw Product 80/20 Tungsten Copper Alloy Tube – Forged Tungsten , The product will supply to all over the world, such as: Greece, Porto, Hamburg, We welcome you to visit our company & factory and our showroom displays various products that will meet your expectations. Meanwhile, it is convenient to visit our website. Our sales staff will try their best to provide you with the best services. If you need more information, please do not hesitate to contact us via E-mail, fax or telephone.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.