Professional Design Molybdenum Tube Pipe - Factory source 99.95% Purity Moly Disc Molybdenum Sheet – Forged Tungsten

Professional Design Molybdenum Tube Pipe - Factory source 99.95% Purity Moly Disc Molybdenum Sheet – Forged Tungsten Detail:

The client satisfaction is our primary concentrate on. We uphold a consistent level of professionalism, top quality, credibility and service for Factory source 99.95% Purity Moly Disc Molybdenum Sheet, We welcome customers all over the word to contact us for future business relationships. Our products are the best. Once Selected, Perfect Forever!

The client satisfaction is our primary concentrate on. We uphold a consistent level of professionalism, top quality, credibility and service for Molybdenum Disc, Molybdenum Sheet, Molybdenum Slab, We are adhering to the philosophy of “attracting customers with the best solutions and excellent service”. We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

Chemical composition:

| Main and minor components | Min.content(%) | ASTM B386 (361) |

| Mo | Balance | balance |

| Ti | 0.40-0.55% | 0.40-0.55% |

| Zr | 0.06-0.12% | 0.06-0.12% |

| Impurities | Max.values (μg/g) | Max.values (μg/g) |

| Al | 10 | - |

| Cu | 20 | - |

| Cr | 20 | - |

| Fe | 20 | 100 |

| K | 20 | - |

| Ni | 10 | 50 |

| Si | 20 | 100 |

| W | 300 | - |

| C | 100-400 | 100-400- |

| H | 10 | - |

| N | 10 | 20 |

| O | 500 | 300 |

| Cd | 5 | - |

| Hg | 1 | - |

| Pb | 5 | - |

Dimensions and tolerances:

| Cold rolled sheets | |||

| Thickness(mm) | Thickness tolerace(±mm) | Maximal width(mm) | Width tolerace(±mm) |

| 0.30-0.50 | 0.028 | 300 | 1.0 |

| Hot rolled sheets | |||

| Thickness(mm) | Thickness tolerace(±mm) | Maximal width(mm) | Width tolerace(±mm) |

| 0.50-0.60 | 0.06 | 850 | 1.6 |

| 0.60-1.00 | 0.08 | 850 | 1.6 |

| 1.00-1.50 | 0.13 | 850 | 2.0 |

| 1.50-2.00 | 0.15 | 850 | 2.0 |

| 2.00-3.60 | 0.18 | 850 | 2.0 |

| 3.60-50.0 | 5% | 1000 | 2.0 |

Length tolerance:

The length tolerance for all dimension is maximal +5/-0 mm.

Flatness: max. 4 % (measuring procedure on the basis of ASTM B 386)

Density: ≥ 10.1 g/cm³

Vickers Hardness: 220-320 HV

Tensile Test:

| Thickness (mm) | Tensile StrengthMin. (MPa) | 0.2% Yield strengtMin.(MPa) | ElongationMin.(%) |

| 0.30-1.00 | 700 | 600 | 5 |

| 1.00-2.50 | 700 | 600 | 10 |

| 2.50-5.00 | 700 | 600 | 12 |

| 5.00-20.00 | 650 | 600 | 10 |

| 20.00-50.00 | 550 | 470 | 5 |

Appearance: The material will be of uniform quality, free from foreign mater, splits and fractures. Bed sheet (not trimmed) may have small edge cracks.

Surface defedts are assessed in the frame of visual inspection.

Surface condition: pickled.

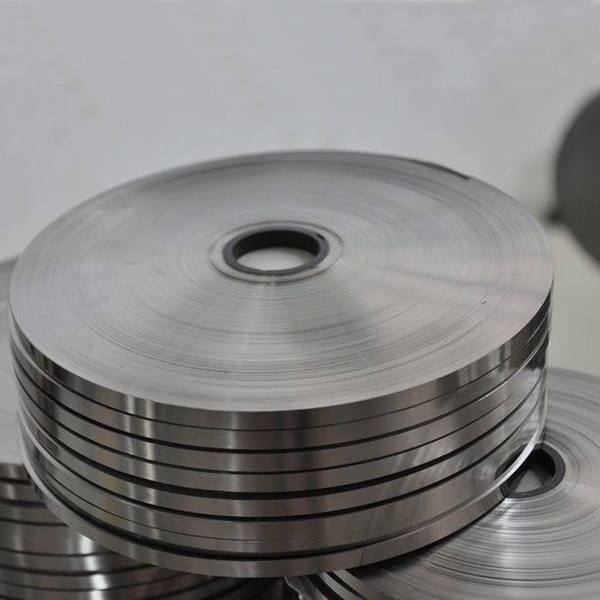

Product detail pictures:

Related Product Guide:

Cute Foals of the Week for Feb. 10 | Rolled Molybdenum Foil

Without Nikola Vucevic, the Orlando Magic’s future is still far away | Tungsten Boats For Heating

Our personnel are always in the spirit of "continuous improvement and excellence", and together with the top-quality good quality solutions, favorable selling price and superior after-sales providers, we try to acquire each customer's rely on for Professional Design Molybdenum Tube Pipe - Factory source 99.95% Purity Moly Disc Molybdenum Sheet – Forged Tungsten , The product will supply to all over the world, such as: Jordan, Gabon, Swedish, To make every client satisfied with us and achieve win-win success, we will continue to try our best to serve and satisfy you! Sincerely looking forward to cooperating with more overseas customers based on mutual benefits and great future business. Thank you.

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.