Popular Design for Tungsten Welding Electrodes - Manufactur standard Pure 99.95% Mo2 Molybdenum Round Rod/bar For Industrial – Forged Tungsten

Popular Design for Tungsten Welding Electrodes - Manufactur standard Pure 99.95% Mo2 Molybdenum Round Rod/bar For Industrial – Forged Tungsten Detail:

Our solutions are greatly recognized and reliable by customers and will fulfill continuously altering financial and social requirements for Manufactur standard Pure 99.95% Mo2 Molybdenum Round Rod/bar For Industrial, Our aim is “blazing new floor, Passing Value”, within the upcoming, we sincerely invite you to definitely grow up with us and generate a brilliant long run collectively!

Our solutions are greatly recognized and reliable by customers and will fulfill continuously altering financial and social requirements for 99.95% Molybdenum Round Rod/bar For Industry And Lab, Molybdenum Bars, Molybdenum Rods, Our company offers the full range from pre-sales to after-sales service, from product development to audit the use of maintenance, based on strong technical strength, superior product performance, reasonable prices and perfect service, we are going to continue to develop, to deliver the high-quality products and solutions and services, and promote lasting cooperation with our customers, common development and create a better future.

Molybdenum rods Chemical composition:

| Main and minor components | Min.content(%) | ASTM B386 (361) |

| Mo | 99.95 | balance |

| Impurities | Max.values (μg/g) | Max.values (μg/g) |

| Al | 10 | - |

| Cu | 20 | - |

| Cr | 20 | - |

| Fe | 20 | 100 |

| K | 20 | - |

| Ni | 10 | 50 |

| Si | 20 | 100 |

| W | 300 | - |

| C | 30 | 100 |

| H | 10 | 20 |

| N | 10 | 70 |

| O | 40 | - |

| Cd | 5 | - |

| Hg | 1 | - |

| Pb | 5 | - |

Dimensions and tolerances:

| Diameter (mm) | Diameter tolerance (mm) |

| Ground | |

| 0.50-0.99 | ±0.007 |

| 1.00-1.99 | ±0.010 |

| 1.00-2.99 | ±0.015 |

| 3.00-15.9 | ±0.020 |

| 16.0-24.9 | ±0.030 |

| 25.0-34.9 | ±0.050 |

| 35.0-3939 | ±0.060 |

| ≥40.0 | ±0.20 |

| Cleaned | |

| 0.50-4.0 | ±2.0% |

| 4.10-10.0 | ±1.5% |

| 15.0-50.0 | ±0.30 |

| 51.0-75.0 | ±0.40 |

| 75.1-120.0 | ±1.00 |

| 121.0-165.0 | ±1.50 |

| Turned | |

| 40.0-49.9 | ±0.30 |

| 50.0-165.0 | ±0.40 |

Length and straightness:

| Diameter (mm) | Production length (mm) | Stiraightness/Meter (mm) | |

| Cleaned | Ground/turned | ||

| 0.50-0.99 | >500 | <2.5 | <2.5 |

| 1.00-9.90 | >300 | <2.0 | <1.5 |

| 10.0-165.0 | >100 | <1.5 | <1.0 |

Length tolerance:

| Diameter 0.50-30.0 mm | ||||||

| Nominal length (mm) | 6-30 | 30-120 | 120-400 | 400-1000 | 1000-2000 | >2000 |

| Length tolerance(mm) | ±0.2 | ±0.3 | ±0.5 | ±0.8 | ±1.2 | ±2.0 |

| Diameter >30.0 mm | ||||||

| Nominal length (mm) | 6-30 | 30-120 | 120-400 | 400-1000 | 1000-2000 | >2000 |

| Length tolerance(mm) | ±1.0 | ±1.5 | ±2.5 | ±4.0 | ±6.0 | ±8.0 |

Density:

1. 00.50-40.0 mm ≥10.15g/cm³

2. 40.1-80.0 mm ≥10.10g/cm³

3. 80.1-120.0 mm ≥10.00g/cm³

4. 120.1-165.0 mm ≥9.90g/cm³

Nondestructive testing: For diameters>15.00 mm:100% ultrasonic testing; For diameters of 0.50-50.0mm:Eddy curent tests on rods with ground surface.

| Diameter(mm) | Tensile strength(MPa) | 0.2% Yield Strength(MPa) | Elongation(%) | Hardness(HV 10) |

| 0.50-3.18 | ≥585 | ≥450 | ≥15 | |

| 3.18-10.30 | ≥515 | ≥380 | ≥15 | |

| 10.32-22.20 | ≥620 | ≥515 | ≥18 | 230-280 |

| 22.20-28.60 | ≥585 | ≥480 | ≥15 | 225-270 |

| 28.60-47.60 | ≥515 | ≥450 | ≥10 | 215-260 |

| 47.60-73.00 | ≥480 | ≥415 | ≥10 | 210-250 |

| 73.00-88.90 | ≥450 | ≥380 | ≥10 | 205-240 |

| 89.00-120.9 | ≥450 | ≥380 | ≥5 | 200-240 |

| 121.0-164.9 | ≥450 | ≥380 | ≥5 | 180-240 |

| 165.0 | ≥450 | ≥380 | ≥- | 180-240 |

Surface condition:

| Surface: | Cleaned | Ground | Turned |

| φ0.50-165mm | φ0.50-50.00mm | φ≥40.00mm | |

| Roughness | Diameter (mm) | Ra (μm) Ground | Ra (μm) Turned |

| ≤2.50 | ≤0.80 | - | |

| 2.5-50.0 | ≤1.00 | - | |

| ≥40.0 | - | ≤3.2 |

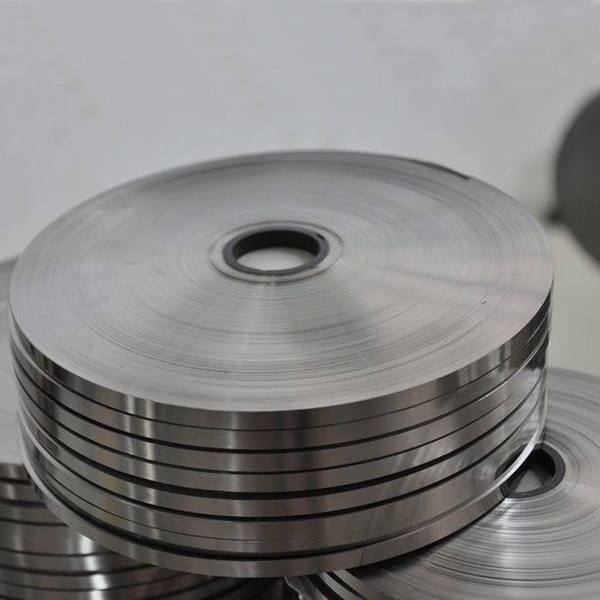

Product detail pictures:

Related Product Guide:

Travis Perkins PLC perks up after Merrill Lynch double-upgrade | Tungsten Boats For Heating

Today MITSU MINING & SMELTING CO LTD. UNS (OTCMKTS:MMSMY) Reported Decrease in Shorted Shares | Niobium Carbide Alloy Powder

As for competitive prices, we believe that you will be searching far and wide for anything that can beat us. We can state with absolute certainty that for such quality at such prices we are the lowest around for Popular Design for Tungsten Welding Electrodes - Manufactur standard Pure 99.95% Mo2 Molybdenum Round Rod/bar For Industrial – Forged Tungsten , The product will supply to all over the world, such as: Malaysia, Bolivia, Mongolia, our qualify products have good reputation from the world as its most competive price and our most advantage of after-sale service to the clients.we hope we can provide a safe, environmental products and super service to our clients from all of the world and establish strategic partnership with them by our professional standards and unremitting efforts.

We have been cooperated with this company for many years, the company always ensure timely delivery ,good quality and correct number, we are good partners.