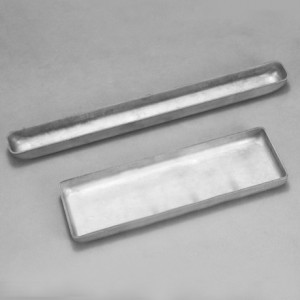

polished surface molybdenum sauqre bar molybdenum rod

The shape of molybdenum bars can be rectangular or cylindrical, and the surface states include alkali washed, polished, polished, and finished. According to their different uses, molybdenum bars can be divided into conventional molybdenum bars, high-temperature molybdenum bars, and steelmaking molybdenum bars.

These characteristics make molybdenum bars play an important role in the industrial field, especially in situations where there are special requirements for material properties.

| Dimensions | As your requirement |

| Place of Origin | Henan, Luoyang |

| Brand Name | FGD |

| Application | Industry,semiconductor |

| Shape | Round, Square |

| Surface | Polished |

| Purity | 99.95% Min |

| Material | Pure Mo |

| Density | 10.2g/cm3 |

| Main components |

Mo>99.95% |

|

Impurity content≤ |

|

|

Pb |

0.0005 |

|

Fe |

0.0020 |

|

S |

0.0050 |

|

P |

0.0005 |

|

C |

0.01 |

|

Cr |

0.0010 |

|

Al |

0.0015 |

|

Cu |

0.0015 |

|

K |

0.0080 |

|

N |

0.003 |

|

Sn |

0.0015 |

|

Si |

0.0020 |

|

Ca |

0.0015 |

|

Na |

0.0020 |

|

O |

0.008 |

|

Ti |

0.0010 |

|

Mg |

0.0010 |

|

Material |

Test Temperature(℃) |

Plate Thickness(mm) |

Pre experimental heat treatment |

|

Mo |

1100 |

1.5 |

1200℃/1h |

|

|

1450 |

2.0 |

1500℃/1h |

|

|

1800 |

6.0 |

1800℃/1h |

|

TZM |

1100 |

1.5 |

1200℃/1h |

|

|

1450 |

1.5 |

1500℃/1h |

|

|

1800 |

3.5 |

1800℃/1h |

|

MLR |

1100 |

1.5 |

1700℃/3h |

|

|

1450 |

1.0 |

1700℃/3h |

|

|

1800 |

1.0 |

1700℃/3h |

1. Our factory is located in Luoyang City, Henan Province. Luoyang is a production area for tungsten and molybdenum mines, so we have absolute advantages in quality and price;

2. Our company has technical personnel with over 15 years of experience, and we provide targeted solutions and suggestions for each customer's needs.

3. All of our products undergo strict quality inspection before being exported.

4. If you receive defective goods, you can contact us for a refund.

1. Prepare raw metal molybdenum bars of appropriate size

2. Cut the metal molybdenum strip according to the design requirements and size requirements

3. According to the design requirements of the product, use a bending machine to bend or fold the metal molybdenum strip into the desired shape

4. According to the needs of product design, punch holes on the metal molybdenum strip using a punch press for fixing or connecting other components

5.If the product requires multiple metal molybdenum bars to be combined together, welding treatment will be carried out to ensure that they are fixed together

6.Finally, the processed metal molybdenum strip is subjected to surface treatment, such as spraying, chrome plating, etc., to improve its appearance and corrosion resistance

7.Conduct quality inspection on the processed metal molybdenum bars to ensure that they meet product requirements and have no defects or issues

The application of molybdenum in the steel industry is of paramount importance, accounting for about 80% of the total consumption of molybdenum. Molybdenum can improve the strength of steel, especially its high-temperature strength, toughness, and corrosion resistance. Stainless steel with a molybdenum content of 4% to 5% is often used in areas with severe corrosion, such as marine equipment and chemical equipment.

Most molybdenum is directly used for steelmaking or cast iron after industrial molybdenum oxide compaction, and a small portion is melted into ferromolybdenum and then used for steelmaking.

Molybdenum rods have many uses in automobiles. One of the main functions of molybdenum rods in automobiles is to produce high-strength, heat-resistant parts. Because molybdenum can withstand high temperatures and provides excellent mechanical properties, it is often used in the manufacture of engine parts such as pistons, valves, and cylinder heads.

In addition, molybdenum is used in the production of steel alloys that are commonly used in the automotive industry for components such as chassis, suspension systems and drivetrain components. Molybdenum helps increase the strength, toughness and corrosion resistance of these steel alloys, making them suitable for use in demanding automotive applications.

Overall, molybdenum rods play a vital role in improving the performance, durability, and safety of various automotive components, helping to improve the overall efficiency and reliability of the vehicle.