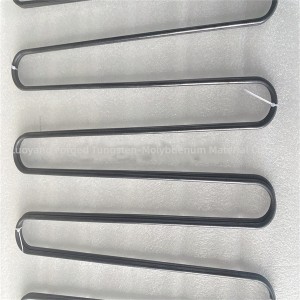

Open molybdenum tube zero cut single crystal sintered

Ingredients: Select appropriate molybdenum powder, additives, and other raw materials according to product specifications and requirements, and perform precise ingredients.

Pressing: Put the prepared raw materials into the mold and press them into shape to obtain a billet with a certain shape and size.

Sintering: Put the pressed billet into the sintering furnace for high-temperature sintering, so that the molybdenum powder in the billet is connected to each other, forming a molybdenum tube with a certain strength.

Processing: Further processing of sintered molybdenum tubes, such as cutting, polishing, cleaning, etc., to meet product specifications and requirements.

It should be noted that molybdenum tubes with different production processes and compositions may have different production process steps and parameters. Therefore, in the actual production process, adjustments and optimizations need to be made according to specific circumstances.

Aerospace: Molybdenum tubes can be used to manufacture rocket engine nozzles, missile engine nozzles, etc., as they can withstand high temperature and high pressure working environments.

Nuclear energy: Molybdenum tubes can be used to manufacture fuel components in nuclear reactors because they have good radiation and corrosion resistance.

Electronics: Molybdenum tubes can be used to manufacture cathode ray tubes, etc., because they can withstand high voltage and high temperature working environments, and have good conductivity and thermal conductivity.

Chemical industry: Molybdenum tubes can be used to manufacture reaction vessels, etc., because they have good corrosion resistance.

Medical: Molybdenum tubes can be used to manufacture X-ray tubes, etc., because they can withstand high voltage and high temperature working environments, and have good conductivity and thermal conductivity.

In summary, molybdenum tubes have broad application prospects and play an important role in various fields.

| Product Name | open molyvdenum tube |

| Material | Mo1 |

| Specification | Customized |

| Surface | Black skin, alkali washed, polished. |

| Technique | Sintering process, machining |

| Meltng point | 2600℃ |

| Density | 10.2g/cm3 |

Wechat:15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com