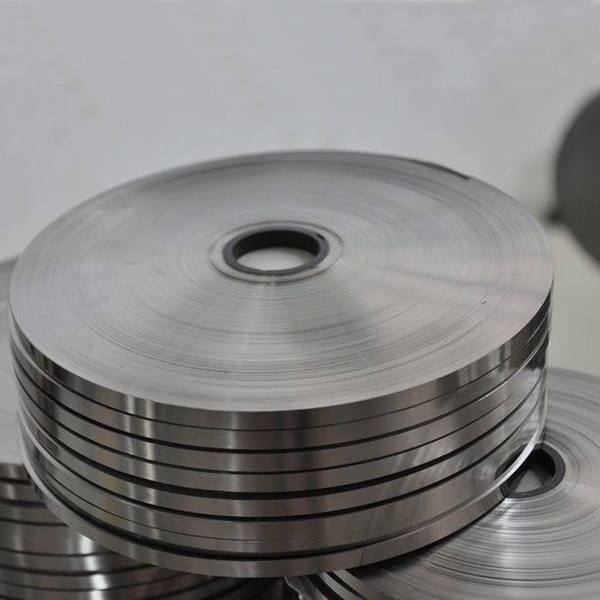

OEM Manufacturer Pure Niobium Pipe - Tungsten hot runner and nozzle – Forged Tungsten

OEM Manufacturer Pure Niobium Pipe - Tungsten hot runner and nozzle – Forged Tungsten Detail:

During the hot runner mold forming process, the plastic melt temperature is accurately controlled in the runner system. Plastics can flow into the cavities in a more uniform state, resulting in consistent quality parts. The hot runner molding parts have good gate quality, low residual stress after demolishing, and small deformation of parts. So many high quality products on the market are produced by hot runner molds.

Since tungsten-molybdenum and its alloy materials have high thermal conductivity, high-temperature strength, creep resistance, wear resistance, and high corrosion resistance, they are suitable materials for making hot runner nozzles in injection molding equipment such as injection molding machines.

Product detail pictures:

Related Product Guide:

Augmented Revenues To Be Witnessed By Hot Stamping Foil by 2019 – 2027 | Niobium Carbide Alloy Powder

2017 Breeders’ Cup Classic Cheat Sheet Presented by Xpressbet | Niobium Carbide Alloy Powder

To meet the customers' over-expected gratification , we have our robust crew to offer our best over-all support which includes marketing, income, coming up with, production, excellent managing, packing, warehousing and logistics for OEM Manufacturer Pure Niobium Pipe - Tungsten hot runner and nozzle – Forged Tungsten , The product will supply to all over the world, such as: Swedish, Slovakia, Philadelphia, We believe that good business relationships will lead to mutual benefits and improvement for both parties. We have established long-term and successful cooperative relationships with many customers through their confidence in our customized services and integrity in doing business. We also enjoy a high reputation through our good performance. Better performance will be expected as our principle of integrity. Devotion and Steadiness will remain as ever.

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!

Write your message here and send it to us