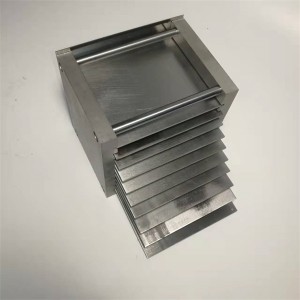

poto yosungunuka ya tungsten crucible ya ng'anjo yotentha kwambiri

Tungsten crucible ndi mtundu wazitsulo zachitsulo za tungsten, zomwe zimagawidwa m'magulu awiri: sintering ndi stamping. Kukonzekera kwa tungsten crucible kumaphatikizapo kupota mtundu, mtundu wa stamping, etc. Njirazi zimapangitsa kuti tungsten crucible ikhale ndi kachulukidwe kwambiri, kutsika kwapamwamba, kulimba kwamphamvu komanso kuuma, pamene mtengo wake ndi wotsika kwambiri, ndipo mtengo wa mankhwala ndi wotsika kwambiri. .

Kugwiritsiridwa ntchito kwakukulu kwa tungsten crucibles kumapindula kuchokera kuzinthu zabwino kwambiri zakuthupi ndi mankhwala, kuphatikizapo malo osungunuka kwambiri, mphamvu zambiri, kukana kwa dzimbiri, ndi kukana kuvala. pa

| Makulidwe | Monga chosowa chanu |

| Malo Ochokera | Luoyang, Henan |

| Dzina la Brand | Chithunzi cha FGD |

| Kugwiritsa ntchito | Makampani |

| Pamwamba | Wopukutidwa |

| Chiyero | 99.95% mphindi |

| Zakuthupi | Tungsten yoyera |

| Kuchulukana | 19.3g/cm3 |

| malo osungunuka | 3400 ℃ |

| Malo ogwiritsira ntchito | Vacuum chilengedwe |

| Kugwiritsa ntchito kutentha | 1600-2500 ℃ |

| Zigawo zazikulu | W >99.95% |

| Zonyansa≤ | |

| Pb | 0.0005 |

| Fe | 0.0020 |

| S | 0.0050 |

| P | 0.0005 |

| C | 0.01 |

| Cr | 0.0010 |

| Al | 0.0015 |

| Cu | 0.0015 |

| K | 0.0080 |

| N | 0.003 |

| Sn | 0.0015 |

| Si | 0.0020 |

| Ca | 0.0015 |

| Na | 0.0020 |

| O | 0.008 |

| Ti | 0.0010 |

| Mg | 0.0010 |

| Zakuthupi | 100% recrystallization kutentha ℃ | (Nthawi yowonjezera: 1 ora)) |

|

| Deformation degree = 90% | Digiri yakusintha=99.99% |

| Woyera W | 1350 | - |

| WVM | - | 2000 |

| WL10 | 1500 | 2500 |

| WL15 | 1550 | 2600 |

| WRE05 | 1700 | - |

| Wre26 | 1750 | - |

1. Fakitale yathu ili mumzinda wa Luoyang, m'chigawo cha Henan. Luoyang ndi malo opangira migodi ya tungsten ndi molybdenum, kotero tili ndi zabwino zonse mumtundu ndi mtengo;

2. Kampani yathu ili ndi anthu ogwira ntchito zaluso omwe ali ndi zaka zopitilira 15, ndipo timapereka mayankho ndi malingaliro omwe amafunikira kwa kasitomala aliyense.

3. Zogulitsa zathu zonse zimawunikiridwa mosamalitsa musanatumizidwe kunja.

4. Ngati mulandira katundu wolakwika, mungathe kulankhulana nafe kuti mubwezedwe.

1. Konzani ufa wa tungsten

(Choyamba, konzani ufa wa tungsten ndikuwuyika kuti mulekanitse ufa wosalala ndi wabwino kwambiri wa tungsten)

2. Gulu lophatikizana

(Batch processing ya tungsten ufa wokhala ndi mankhwala omwewo koma kuchokera kumapangidwe osiyanasiyana)

3. kukanikiza kwa isostatic

(Ikani ufa wa tungsten wophatikizika m'chidebe chosindikizidwa chodzaza ndi madzi, ndikuukakamiza pang'onopang'ono kudzera mu makina osindikizira kuti muchepetse mtunda pakati pa mamolekyu, kuchulukitsa kachulukidwe, ndikuwongolera mawonekedwe azinthuzo popanda kusintha mawonekedwe)

4. Makina opangira ma billet

(Mukamaliza kukanikiza kwa isostatic, kukonza kwa billet kumachitika)

5. Wapakatikati pafupipafupi sintering

(Ikani billet yosakanizidwa mu ng'anjo yapakatikati kuti itenthetse)

6. Kukonza bwino galimoto

(Kutembenuza chopangidwa ndi sintered kuti mupeze miyeso ndi mawonekedwe ake)

7. Yang'anirani zoyikapo

(Yang'anirani crucible ya tungsten yokonzedwa ndikuiyika mutatha kuyanika)

Kusungunuka kwa magalasi a quartz: Ma crucibles a Tungsten amagwiritsidwanso ntchito kwambiri m'ng'anjo zosungunula magalasi a quartz. Monga chimodzi mwa zida zofunika zosungunula galasi la quartz, mphamvu zawo za kutentha kwambiri ndi kukana kwa dzimbiri zimathandiza kuti galasi la quartz lisungunuke ndikupanga mawonekedwe omwe amafunidwa kumalo otentha kwambiri.

Kusinthika kwa crucible kumayambitsidwa ndi kufalikira kosagwirizana kwa magawo osiyanasiyana a crucible chifukwa cha kutentha kwakukulu komanso kosafanana. Kutentha kofulumira komanso kosafanana kwa crucible kuyenera kupewedwa.

Kutentha kovomerezeka ndi 1600-2500 madigiri Celsius.