Carbide Nozzle Tungsten Cemented Carbide

Kupanga ma nozzles a tungsten carbide kumaphatikizapo njira zingapo zofunika: Kukonzekera ufa: Tungsten carbide ufa umasakanizidwa ndi tinthu tating'ono ta binder, monga cobalt, kuti awonjezere mphamvu ndi kulimba kwake.

Kusakaniza: Sakanizani ufa wa tungsten carbide ndi zomangira bwino kuti mutsimikizire kusakanikirana. Kuphatikizika: Ufa wosakanizikawo umayikidwa mu nkhungu ndipo kuthamanga kwakukulu kumayikidwa kuti apange mawonekedwe omwe akufuna. Pre-sintering: Zigawo zophatikizika zimayikidwa kale pa kutentha kwambiri kuti zisungunuke pang'ono zinthu zomangira ndikumangirira tinthu tating'ono ta tungsten carbide. Kupanga: Magawo omwe amapangidwa kale amapangidwa ndikupangidwa kuti akwaniritse miyeso yomaliza ndi kumaliza kwapamwamba kofunikira pamilomo ya carbide. Sintering: Zigawo zooneka bwino zimayikidwa pazitsulo zotentha kwambiri mumlengalenga wolamulidwa, zomwe zimalola kuti tinthu tating'onoting'ono ta tungsten tigwirizane pamodzi molimba kwambiri kuti zikhale zolimba komanso zolimba. Kumaliza: Pambuyo pa sintering, ma carbide nozzles nthawi zambiri amachitidwa maopaleshoni achiwiri monga kugaya, kupukuta ndi kupaka kuti akwaniritse zomaliza zomwe akufuna komanso magwiridwe antchito.

Pamasitepe onsewa, njira zowongolera bwino zimayendetsedwa kuti zitsimikizire kuti ma tungsten carbide nozzles akukumana ndi kuuma, kukana kuvala komanso kulondola kwamayendedwe. Njira zopangira izi zimathandizira kupanga ma nozzles apamwamba kwambiri pazogwiritsa ntchito zosiyanasiyana zamafakitale, kuphatikiza kuphulika kwa mchenga, kupopera mankhwala ndi kudula jet yamadzimadzi.

Carbide nozzles zopangidwa ndi carbide zimagwiritsidwa ntchito kwambiri m'mafakitale osiyanasiyana chifukwa cha kuuma kwawo kwakukulu, kukana kuvala komanso kukhazikika kwamafuta. Ma nozzles awa amagwiritsidwa ntchito kwambiri pazida zophulitsira mchenga, makina odulira ndege zamadzi ndi makina opaka utoto. Katundu wa carbide amapanga chisankho chabwino kwambiri pakugwiritsa ntchito motere:

Sandblasting: Carbide nozzles amagwiritsidwa ntchito pophulitsa mchenga kukankhira zinthu zowononga (monga mchenga kapena grit) pamwamba pa liwiro lalikulu ndicholinga choyeretsa, kukonza pamwamba, kapena kupha. Kulimba kwa Carbide ndi kukana kuvala kumatsimikizira moyo wautali wautumiki wa nozzles m'malo ovuta komanso ovuta. Kudula kwa Waterjet: Mu makina odulira madzi, mphuno ya carbide imagwiritsidwa ntchito kuyang'ana mtsinje wamadzi wothamanga kwambiri wosakanikirana ndi particles abrasive kuti adule molondola zinthu zosiyanasiyana, kuphatikizapo zitsulo, miyala, galasi ndi ma composite. Kutha kwa carbide kupirira mphamvu zowononga za jeti yamadzi yodzaza ndi abrasive ndikofunikira kuti mphuno ikhale yosasunthika. Kupopera mbewu mankhwalawa: Carbide nozzles amagwiritsidwanso ntchito popopera mbewu mankhwalawa pomwe amapaka atomi kapena kumwaza zokutira zamadzimadzi, utoto kapena zomatira pamwamba molondola kwambiri. Kukaniza kwa Carbide ndi kukhazikika kwamafuta kumatsimikizira magwiridwe antchito okhazikika komanso odalirika a njira zokutirazi, ngakhale pogwira ntchito ndi zonyezimira kapena zowoneka bwino kwambiri.

Ponseponse, kugwiritsa ntchito ma carbide nozzles opangidwa kuchokera ku carbide kumatha kukulitsa zokolola, kukonza magwiridwe antchito ndikuchepetsa nthawi yokonzanso muntchito zosiyanasiyana zamafakitale zomwe zimakhudzana ndi kunyamula zinthu mwachangu kwambiri kapena kubalalitsidwa kolondola kwamadzimadzi.

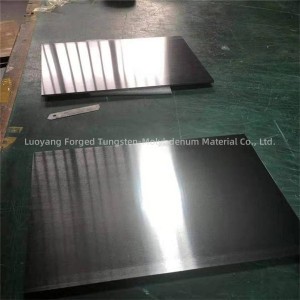

| Dzina lazogulitsa | Carbide Nozzle Tungsten Cemented Carbide |

| Zakuthupi | W |

| Kufotokozera | Zosinthidwa mwamakonda |

| Pamwamba | Khungu lakuda, alkali otsukidwa, opukutidwa. |

| Njira | Sintering ndondomeko, Machining |

| Meltng point | 3400 ℃ |

| Kuchulukana | 19.3g/cm3 |

Wechat: 15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com