Pulagi ya Molybdenum mandrel kuboola chitoliro chopanda chitsulo

Kupanga mapulagi a molybdenum mandrel nthawi zambiri kumaphatikizapo kuphatikiza makina, kupanga zitsulo komanso kumaliza. Zotsatirazi ndizomwe zimachitika pakupanga njira:

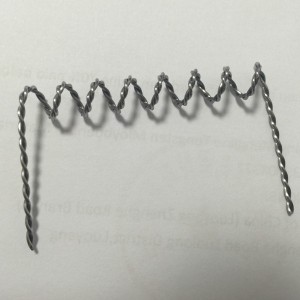

Kusankha kwazinthu zopangira: Sankhani ndodo zapamwamba za molybdenum kapena ndodo ngati zida zopangira mapulagi a mandrel. Molybdenum inasankhidwa chifukwa cha malo ake osungunuka kwambiri, mphamvu ndi kukana kwa dzimbiri, zomwe zimapangitsa kuti zikhale zoyenera kugwiritsa ntchito zomwe zimafuna kutentha kwambiri komanso makina. Machining: Ndodo ya molybdenum imapangidwa kuti ipange mawonekedwe oyamba a pulagi ya mandrel. Izi zingaphatikizepo kutembenuza, mphero kapena kubowola kuti mupeze miyeso yofunikira ndi mawonekedwe apamwamba. Makina a CNC (kuwongolera manambala apakompyuta) amalola kupanga ndikudula bwino. Kupanga Chitsulo: Chopanda kanthu cha molybdenum chopangidwa ndi makina chimayikidwa pazitsulo zopanga zitsulo monga kupindika, kugwedeza kapena kutulutsa kuti apange mawonekedwe enieni ndi ma contour a pulagi ya mandrel. Mwachitsanzo, ngati mawonekedwe a tapered kapena conical amafunikira pulagi ya mandrel, njira zopangira zitsulo zimagwiritsidwa ntchito kukwaniritsa geometry yomwe mukufuna. Kuchiza kutentha: Pambuyo popanga ndi kupanga, pulagi ya molybdenum mandrel ikhoza kuchitidwa chithandizo cha kutentha kuti iwonjezere mphamvu zake zamakina monga mphamvu ndi kuuma. Kutentha kwapamwamba kwambiri kapena sintering kumatha kugwiritsidwa ntchito kukhathamiritsa microstructure ndikuchotsa kupsinjika kotsalira. KUMALIZA: Mapulagi a Molybdenum mandrel amachitidwa ntchito yomaliza kuti atsimikizire kulondola kwazithunzi, kusalala pamwamba ndikuchotsa zolakwika zilizonse. Izi zingaphatikizepo kupukuta, kugaya kapena njira zina zokonzekera pamwamba kuti mukwaniritse zofunikira zapamtunda ndi kulolerana kwa geometric. Kuwongolera Ubwino: Panthawi yonse yopangira, njira zowongolera zabwino zimayendetsedwa kuti ziwone ndikuwonetsetsa kulondola kwazinthu, kukhulupirika kwazinthu komanso mtundu wonse wa mapulagi a molybdenum mandrel. Njira zoyesera zosawononga, dimensional metrology ndi kuyang'ana kowoneka zingagwiritsidwe ntchito kuti zitsimikizire kuti zikutsatira zomwe zanenedwa. Potsatira njira zopangira izi, opanga amatha kupanga mapulagi a molybdenum mandrel okhala ndi mawonekedwe ndi magwiridwe antchito omwe amafunikira kuti agwiritse ntchito.

Mapulagi a Molybdenum mandrel amagwiritsidwa ntchito kwambiri popanga zitoliro zopanda msoko ndi mafakitale opanga zitoliro. Mapulagi awa amalowetsedwa muzitsulo zopanda kanthu (machubu kapena mapaipi) panthawi yopanga kuti zitsimikizire zolondola komanso kupewa zolakwika monga ovality kapena waviness. Zinthu za molybdenum zinasankhidwa chifukwa cha mphamvu zake zotentha kwambiri, kukana dzimbiri, komanso kupirira kutentha kwakukulu ndi zovuta zomwe zimakhudzidwa ndi kupanga chitoliro. Mapulogalamu apadera a mapulagi a molybdenum mandrel akuphatikizapo: Kupanga chitoliro chosasunthika: Mapulagi a Molybdenum mandrel amagwiritsidwa ntchito popanga mapaipi opanda msoko monga zida zopangira kuti asunge mkati mwake ndi khalidwe lapamwamba la workpiece. Mapulagi a mandrel awa ndi ofunikira kuti atsogolere ndikuthandizira chogwirira ntchito kuti chikwaniritse miyeso yomwe mukufuna ndikumaliza pamwamba pomwe ikupita kuboola kwamafuta, kutambasula ndi kugubuduza. Kugudubuza ndi kuboola kotentha: Panthawi yotentha ndi kuboola, mapulagi a molybdenum mandrel amagwiritsidwa ntchito pofuna kupewa kupangika kwa makwinya, eccentricity ndi kuwonongeka kwa pamwamba pa mapaipi opanda msoko. Popereka chithandizo chamkati ndi mawonekedwe, mapulagi a mandrel amathandiza kuti apange zinthu zapamwamba, zofananira ndi miyeso yofanana. Malo Otentha Kwambiri: Kugwiritsa ntchito mapulagi a molybdenum mandrel kumakhala kopindulitsa kwambiri m'malo opangira kutentha kwambiri, komwe kusungunuka kwazinthuzo komanso kutentha kwambiri kumalola kupirira zovuta zomwe zimachitika panthawi yopanga chitoliro.

Ponseponse, mapulagi a molybdenum mandrel amagwira ntchito yofunika kwambiri pakuwonetsetsa kuti mawonekedwe ake ndi olondola, apamwamba komanso kukhulupirika kwa machubu opanda msoko, potsirizira pake amathandizira kupanga magwiridwe antchito apamwamba pamafakitale osiyanasiyana monga magalimoto, mlengalenga, mafuta ndi gasi, ndi zina zambiri dipatimenti yamankhwala.

| Dzina lazogulitsa | Pulogalamu ya Molybdenum mandrel |

| Zakuthupi | Mo |

| Kufotokozera | Zosinthidwa mwamakonda |

| Pamwamba | Khungu lakuda, alkali otsukidwa, opukutidwa. |

| Njira | Sintering ndondomeko, Machining |

| Meltng point | 2600 ℃ |

| Kuchulukana | 10.2g/cm3 |

Wechat: 15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com