99.95% Molybdenum flange Amagwiritsidwa ntchito polumikizira mapaipi

Kupanga kwa 99.95% molybdenum flanges kumaphatikizapo njira zingapo zofunika kuti zitsimikizire ubwino, kulondola komanso kuyenerera kwa malumikizidwe a zitoliro m'mafakitale osiyanasiyana. Zotsatirazi ndizofotokozera mwachidule njira yopangira 99.95% molybdenum flange:

1. Kusankha kwazinthu: Chinthu choyamba chopanga ma molybdenum flanges ndikusankha zipangizo zoyera kwambiri za molybdenum. Zipangizo zimayenera kukumana ndi milingo yoyera, yomwe nthawi zambiri imakhala 99.95%, kuwonetsetsa kuti zinthu zofunika monga kukana kutentha ndi dzimbiri. Zida za molybdenum zimatengedwa kuchokera kwa ogulitsa odziwika kuti atsimikizire chiyero chawo komanso kusasinthika.

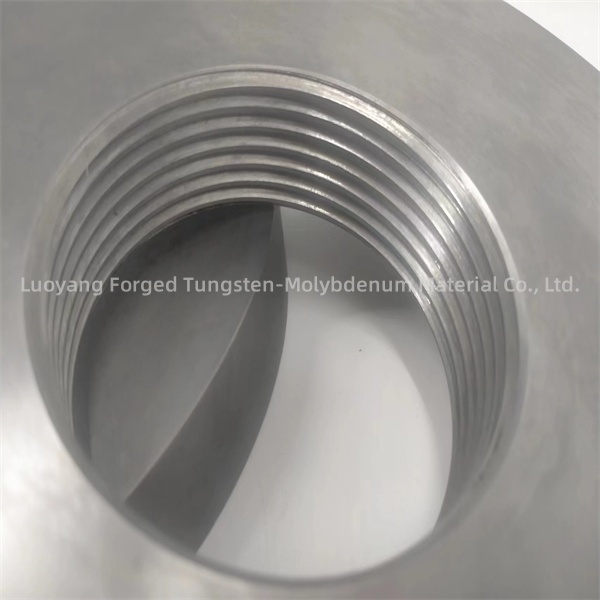

2. Kupanga ndi kupanga: Ukadaulo waukadaulo waukadaulo umagwiritsidwa ntchito popanga zinthu za molybdenum kuti apange flange. Izi zitha kuphatikizapo CNC (kuwongolera manambala apakompyuta) mphero, kutembenuza kapena njira zina zopangira makina kuti apange molybdenum mukusintha komwe mukufuna. Kukonzekera kolondola ndikofunikira kuti muwonetsetse kukula kwake ndi kutha kwa flange.

3. Kulumikiza ndi kuwotcherera: Nthawi zina, ma flange a molybdenum angafunike kulumikiza kapena kuwotcherera kuti apange gawo lomaliza. Njira zowotcherera zaukadaulo zoyenera molybdenum, monga kuwotcherera kwa ma elekitironi kapena kuwotcherera kwa laser, zitha kugwiritsidwa ntchito kuwonetsetsa kuti flange ndi kukhulupirika kwake komanso kukhalabe oyera.

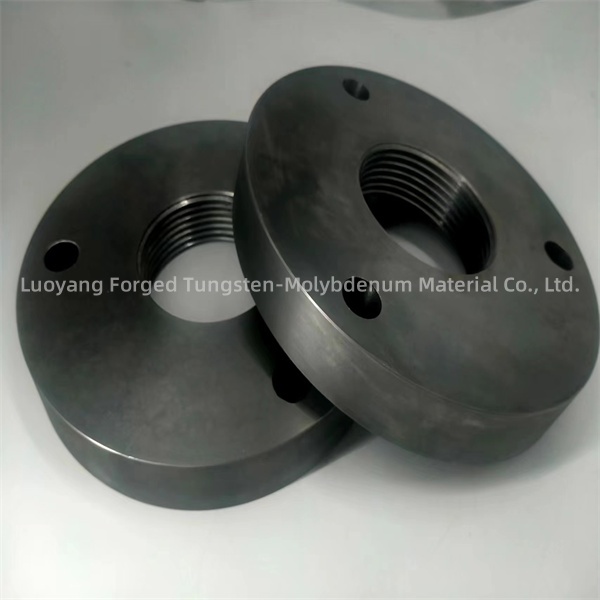

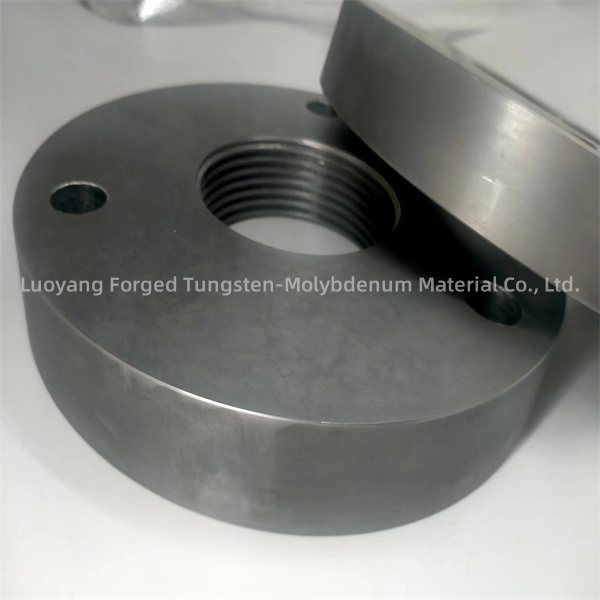

4. Chithandizo chapamwamba: Malingana ndi zofunikira zenizeni za ntchito, ma molybdenum flanges amatha kuchitidwa pamwamba kuti apititse patsogolo ntchito yawo. Izi zitha kuphatikizirapo njira monga kupukuta, kupukutira kapena zokutira kuti flange isavutike ndi dzimbiri ndi kuvala.

5. Kuwongolera kwaubwino: Pa nthawi yonse yopangira, njira zowongolera zowongolera zimayendetsedwa kuti zitsimikizire kulondola kwa mawonekedwe, mawonekedwe a pamwamba ndi kukhulupirika kwa zinthu za molybdenum flange. Izi zitha kuphatikiza kugwiritsa ntchito zida zowunikira zapamwamba monga makina oyezera (CMM) ndi njira zoyesera zosawononga kuti zitsimikizire kuti flange ikukwaniritsa zofunikira.

6. Kuyang'ana komaliza ndi kuyika: Pambuyo pa kupangidwa kwa molybdenum flange ndikukonzedwa, idzayang'aniridwa komaliza kuti iwonetsetse kuti ikukwaniritsa miyezo yolimba yolumikizira chitoliro. Izi zikuphatikiza kutsimikizira kukula kwa flange, kumaliza kwapamwamba komanso mtundu wonse. Pambuyo poyang'anitsitsa bwino, flange idzapakidwa mosamala kuti iteteze panthawi yoyendetsa ndi kusunga.

Ndikofunika kuzindikira kuti njira zopangira 99,95% molybdenum flanges ziyenera kutsata malamulo ndi miyezo yamakampani, kuphatikizapo zokhudzana ndi chiyero chakuthupi, ukhondo ndi kulondola kwazithunzi. Kuphatikiza apo, malo opangira zinthu ayenera kukhala ndi malo aukhondo komanso oyendetsedwa bwino kuti apewe kuipitsidwa kwa flange.

99.95% Molybdenum flanges ali ndi ntchito zosiyanasiyana, ndipo chifukwa cha mawonekedwe apadera a molybdenum, amagwiritsidwa ntchito kwambiri m'madera osiyanasiyana a mafakitale. Nazi zina zofunika za 99.95% molybdenum flanges:

1. Kutentha kwakukulu ndi malo owononga: Molybdenum flange amagwiritsidwa ntchito m'mafakitale omwe amatentha kwambiri ndi malo owononga kwambiri. Mwachitsanzo, popanga mankhwala, kuyenga ndi kupanga zitsulo, ma molybdenum flanges amagwiritsidwa ntchito polumikizana ndi mapaipi kuti athe kupirira kutentha kwambiri komanso kukana dzimbiri kuchokera ku mankhwala oopsa.

2. Makina a vacuum ndi ntchito zamlengalenga: Ma Flanges a Molybdenum ndi zigawo zofunika kwambiri pazitsulo za vacuum, kuphatikizapo zomwe zimagwiritsidwa ntchito mumlengalenga, kupanga semiconductor ndi malo ofufuzira. Malo awo osungunuka kwambiri komanso kukana kutulutsa mpweya amawapangitsa kukhala oyenera kupanga zisindikizo zodalirika m'zipinda zosungiramo vacuum ndi malo otsekemera kwambiri.

3. Kugwiritsa Ntchito Mphamvu ndi Nyukiliya: Molybdenum flanges angagwiritsidwe ntchito pamagetsi okhudzana ndi mphamvu, kuphatikizapo magetsi a nyukiliya, ma reactors ofufuza ndi malo ena omwe kukana kutentha ndi kudalirika kuli kofunika kwambiri. Amagwiritsidwa ntchito polumikizira mapaipi onyamula madzi otentha kwambiri komanso mpweya m'malo ovutawa.

4. Kupanga kwa semiconductor ndi zamagetsi: Molybdenum flanges ndi gawo lofunika kwambiri la semiconductor ndi njira zopangira zamagetsi, makamaka m'madera otchedwa ultra-high vacuum (UHV). Amagwiritsidwa ntchito popanga njira zoperekera vacuum ndi gasi, kuwonetsetsa kulumikizana kodalirika munjira zovuta monga kuyika filimu yopyapyala ndi kupanga semiconductor.

5. Makina othamanga kwambiri: Molybdenum flanges amagwiritsidwa ntchito m'makina othamanga kwambiri, monga omwe ali m'mafakitale a mankhwala ndi petrochemical, komwe amapereka maulumikizidwe otetezeka komanso okhazikika a mapaipi omwe amanyamula mpweya wothamanga kwambiri ndi zakumwa.

6. Kafukufuku ndi Chitukuko: Ma Flanges a Molybdenum amagwiritsidwa ntchito pofufuza ndi chitukuko, kuphatikizapo ma laboratories ndi malo oyesera, zida zapadera za kutentha kwakukulu, kupanikizika kwakukulu ndi ntchito za vacuum.

Muzochita zonsezi, zinthu zapamwamba za molybdenum, kuphatikizapo kutentha kwapamwamba, kukana kwa dzimbiri ndi mphamvu zamakina, zimapangitsa 99.95% molybdenum flanges kukhala gawo lofunikira poonetsetsa kukhulupirika ndi kudalirika kwa malumikizidwe a chitoliro m'madera ovuta a mafakitale. Kuphatikiza apo, njira zolondola zopangira ndi kuwongolera zabwino zomwe zimakhudzidwa popanga ma molybdenum flanges zimatsimikizira kuti akukwaniritsa zofunikira zomwe akufuna.

| Dzina lazogulitsa | 99.95% Molybdenum Flange |

| Zakuthupi | Mo1 |

| Kufotokozera | Zosinthidwa mwamakonda |

| Pamwamba | Khungu lakuda, alkali otsukidwa, opukutidwa. |

| Njira | Sintering ndondomeko, Machining |

| Meltng point | 2600 ℃ |

| Kuchulukana | 10.2g/cm3 |

Wechat: 15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com