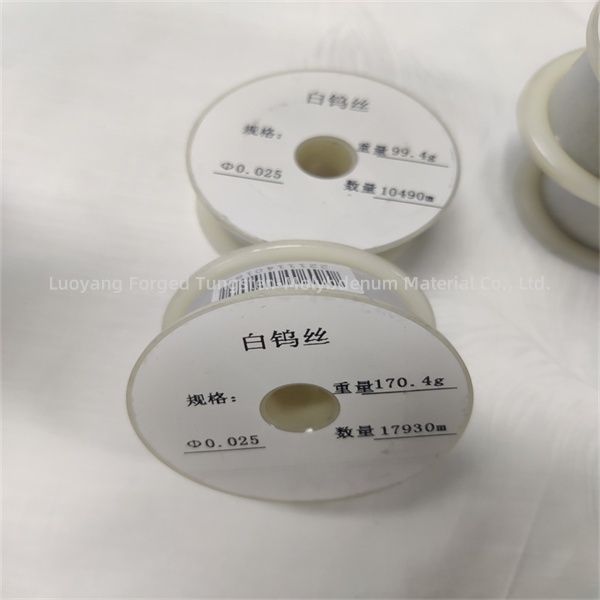

0.025mm tungsten waya 99.95% koyera tungsten ulusi

Kuwonjezera pa kugwiritsidwa ntchito mu mababu a kuwala, waya wa tungsten amagwiritsidwa ntchito kwambiri ngati chigawo chotulutsa kuwala mu zipangizo zina zamagetsi monga ma TV, zowonetsera, lasers, vacuum electronic devices, ndi machubu amagetsi. Zigawo zotulutsa mawaya a tungsten pazida izi zimatha kutulutsa kuwala kwambiri, kukhazikika kwabwino, komanso kuyatsa kwanthawi yayitali, kukwaniritsa zosowa zosiyanasiyana zamagwiritsidwe ntchito.

| Diameter | Zosintha mwamakonda |

| Malo Ochokera | Henan, Luoyang |

| Dzina la Brand | Chithunzi cha FGD |

| Kugwiritsa ntchito | Medical, Kutentha element, Viwanda |

| Maonekedwe | Molunjika |

| Pamwamba | Wopukutidwa |

| Chiyero | 99.95% mphindi |

| Zakuthupi | Woyera W |

| Kuchulukana | 19.3g/cm3 |

| Mtengo wa MOQ | 1kg pa |

| Kutalika kwa zinthu za silikad,mm | Kulemera kwa 200mm gawo la silika, mg | Kutalika kochepa,m |

| 5≤d≤10 | 0.075-0.30 | 300 |

| 10≤d≤60 | >0.30-10.91 | 400 |

| 60<d≤100 | >10.91-30.30 | 350 |

| 100<d≤150 | >30.30-68.18 | 200 |

| 150<d≤200 | >68.18~121.20 | 100 |

| 200<d≤350 | >121.20~371.19 | 50 |

| 350<d≤700 | / | Zofanana ndi kulemera kwa 75g |

| 700<d≤1800 | / | Zofanana ndi kulemera kwa 75g |

| Kutalika kwa silika ld, μm | Kulemera kwa 200mm gawo la silika, mg | Kulemera kwa 200mm gawo la silika kupatuka | Kupatuka kwa diameter % | |||

| 0 mlingo | Ndi mlingo | II mlingo | Ndi mlingo | II mlingo | ||

| 5≤d≤10 | 0.075-0.30 | / | ±4 | ±5 | / | / |

| 10≤d≤18 | >0.30–0.98 | / | ±3 | ±4 | / | / |

| 18≤d≤40 | >0.98–4.85 | ±2 | ±2.5 | ±3 | / | / |

| 40<d≤80 | >4.85–19.39 | ±1.5 | ±2.0 | ±2.5 | / | / |

| 80<d≤300 | 19.39-272.71 | ±1.0 | ±1.5 | ±2.0 | / | / |

| 300<d≤350 | >272.71–371.19 | / | ±1.0 | ±1.5 | / | / |

| 350<d≤500 | / | / | / | / | ±1.5 | ±2.0 |

| 500<d≤1800 | / | / | / | / | ±1.0 | ±1.5 |

1. Fakitale yathu ili mumzinda wa Luoyang, m'chigawo cha Henan. Luoyang ndi malo opangira migodi ya tungsten ndi molybdenum, kotero tili ndi zabwino zonse mumtundu ndi mtengo;

2. Kampani yathu ili ndi anthu ogwira ntchito zaluso omwe ali ndi zaka zopitilira 15, ndipo timapereka mayankho ndi malingaliro omwe amafunikira kwa kasitomala aliyense.

3. Zogulitsa zathu zonse zimawunikiridwa mosamalitsa musanatumizidwe kunja.

4. Ngati mulandira katundu wolakwika, mungathe kulankhulana nafe kuti mubwezedwe.

1.Kuchotsa zinthu zopangira

2.mankhwala mankhwala

3. Kuchepetsa kwa tungsten ufa

4.Kupondereza ndi kuyimba

5. Kujambula

6.Annealing

7. Chithandizo chapamwamba

8. Kuwongolera Ubwino

9. Kuyika

1. Zipangizo zamagetsi ndi zida za vacuum: Waya wa Tungsten amagwiritsidwa ntchito ngati choyimira ma elekitironi ndi chinthu chotenthetsera pamfuti za ma elekitironi otentha pakugwiritsa ntchito. Amagwiritsidwanso ntchito kwambiri pazida zochotsera vacuum monga machubu otentha a electron, ma microscopes a electron, ndi zida za ionization ya gasi.

2. Munda wowunikira: Chifukwa cha kuthekera kwake kutulutsa kuwala kowala pa kutentha kwakukulu komanso kukana kusweka, waya wa tungsten amagwiritsidwa ntchito kwambiri ngati gwero lowunikira mu mababu achikhalidwe a incandescent.

3. Chotenthetsera chokana: Malo osungunuka kwambiri komanso kutentha kwapamwamba kwa waya wa tungsten kumapangitsa kuti ikhale chinthu choyenera chothandizira kutentha. Nthawi zambiri amagwiritsidwa ntchito m'zida zamagetsi zamagetsi zam'nyumba ndi mafakitale monga masitovu amagetsi, mavuni, ndi ma iron.

4. Kuwotcherera ndi kudula: Waya wa Tungsten amagwiritsidwa ntchito kwambiri ngati zinthu za elekitirodi pakuwotcherera kwamphamvu kwambiri komanso kudula monga kuwotcherera kwa argon arc, kudula laser, ndi kuwotcherera kwa ma elekitironi. Malo ake osungunuka kwambiri komanso kukana kwa dzimbiri kumapangitsa kukhala chisankho chabwino poyambitsa ma arc komanso kutulutsidwa kwaposachedwa munjira izi.

5. Chemical reactors: Mu ma reactors ena amankhwala, mawaya a tungsten amagwiritsidwa ntchito ngati chothandizira ndi zida zothandizira kuti apititse patsogolo kuchita bwino komanso kukhazikika.

Kuphatikiza pa zomwe tafotokozazi, waya wa tungsten amagwiritsidwanso ntchito kwambiri m'makampani opanga nsalu, zakuthambo, mafakitale a nyukiliya, ndi zamankhwala.

Kutalika kwa waya wa tungsten kumafunika kutsimikiziridwa molingana ndi momwe amagwiritsira ntchito. Nthawi zambiri, kung'ung'udza kwake kumapangitsa kuti waya wa tungsten ukhale wocheperako, koma mphamvu yonyamula katundu ndi moyo wautumiki zidzachepa. Choncho, m'pofunika kusankha malinga ndi zosowa zapadera.

Zida za waya wa tungsten zimakhudza kwambiri ntchito yake. Tungsten yoyera imakhala ndi mphamvu zotentha kwambiri komanso kukana dzimbiri kuposa aloyi ya tungsten. Choncho, pamene chiyero chapamwamba komanso kukana kwa dzimbiri kumafunika, tikulimbikitsidwa kusankha waya wa tungsten woyera; Tungsten alloy imakhala ndi mphamvu komanso ductility, ndikupangitsa kuti ikhale yoyenera pazinthu zina zapadera monga spark machining, vacuum electronic equipment, ndi zina.

Nthawi yosungunuka ya waya wa tungsten wotenthedwa mu vacuum imadalira kuchuluka kwa evaporation kwa tungsten. Ndipo kutentha kwa waya wa tungsten mu mpweya kumatulutsa tungsten oxide. Malo osungunuka a tungsten ndi madigiri 3410. Malo osungunuka a tungsten oxide, WO3, ndi madigiri 1400-1600. Pazikhalidwe zogwirira ntchito, kutentha kwa filament kumakhala pafupifupi madigiri 2500, ndipo WO3 imasungunuka mofulumira pa kutentha kumeneku, zomwe zimapangitsa kuti filament isungunuke mwamsanga mumlengalenga.