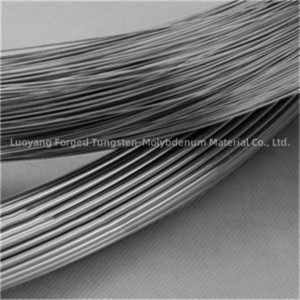

Molybdenum wire for EDM (Electrical Discharge Machining) cutting.

The production of molybdenum wire for EDM (Electrical Discharge Machining) cutting involves several key steps, each critical for ensuring the wire's high quality, precision, and performance characteristics. Here's an overview of the typical production process:

Molybdenum Powder Production

Purification: Molybdenum ore is purified to produce molybdenum oxide, which is then reduced to molybdenum powder.

Blending: The powder is blended to achieve the desired chemical composition.

Powder Metallurgy

Pressing: The molybdenum powder is pressed into a compacted form under high pressure.

Sintering: The compacted powder is heated in a furnace below its melting point to bond the particles together, forming a solid mass.

Metal Drawing

Swaging/Hot Drawing: The sintered molybdenum is initially formed into rods through a hot drawing or swaging process, which reduces its diameter and increases its length without changing its volume.

Wire Drawing: The rods are further drawn through a series of dies to progressively reduce their diameter to the desired size for EDM wire. This process is performed under controlled conditions to prevent wire breakage and ensure uniform diameter.

Cleaning and Annealing

Cleaning: The drawn wire is cleaned to remove any lubricants, oxides, or other contaminants from its surface.

Annealing: The wire is then annealed, a heat treatment process that relieves internal stresses induced during drawing, enhancing its ductility and electrical conductivity.

Inspection and Packaging

Quality Control: The final wire undergoes rigorous quality control tests to verify its diameter, tensile strength, surface quality, and electrical properties.

Spooling and Packaging: Once approved, the wire is spooled onto reels of specified lengths and packaged for shipping, ensuring protection against damage and contamination.

This production process is carefully controlled and monitored to ensure that the molybdenum wire meets the stringent requirements necessary for efficient and precise EDM cutting applications.

Precision Metal Cutting

Complex Geometries: Ideal for cutting intricate shapes and fine features in hard metals and alloys that are difficult to machine with traditional methods.

Tight Tolerances: Enables manufacturing of components with high precision and tight tolerances, crucial for aerospace, automotive, and precision engineering industries.

Mold and Die Making

Mold Manufacturing: Used in the production of molds for plastic injection molding, die casting, and forging, allowing for the creation of detailed and complex mold designs.

Die Manufacturing: Essential for fabricating stamping dies, extrusion dies, and other types of dies used in metal forming processes.

Aerospace and Automotive Components

Aerospace Parts: Produces components with the strength and precision required for aerospace applications, including engine parts, landing gear components, and instrumentation.

Automotive Parts: Used to manufacture critical automotive components, such as injector nozzles, gearbox parts, and components with complex geometries.

Medical Device Manufacturing

Surgical Instruments: Enables the creation of intricate surgical instruments and devices, benefiting from the wire's ability to produce precise cuts and shapes.

Implants: Suitable for fabricating medical implants that require high precision and biocompatibility.

Electronics and Semiconductor Industry

Semiconductor Equipment: Used in the manufacturing of semiconductor devices and components, where precision and material integrity are paramount.

Circuit Board Production: Assists in the production of printed circuit boards (PCBs) and microelectronic devices, enabling the creation of fine patterns and details.

Molybdenum wire's versatility and superior properties make it a preferred choice for EDM cutting across these diverse applications, driving innovation and precision in manufacturing.

| Specification | Description |

|---|---|

| Diameter | 0.1mm - 0.3mm (common sizes) |

| Material | Pure Molybdenum |

| Melting Point | Approximately 2623°C (4753°F) |

| Tensile Strength | 700-1000 MPa (depending on diameter) |

| Electrical Conductivity | High |

| Surface Finish | Smooth, clean, without any defects |

| Spool Size | Varies (e.g., 2000m, 2400m per spool) |

| Application | Suitable for high-precision EDM cutting |

| Features | High durability, efficiency in cutting |

| Compatibility | Compatible with various EDM machines |

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com