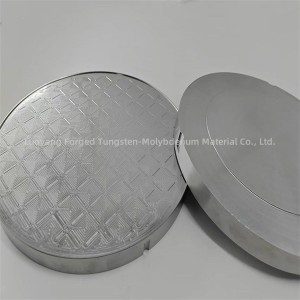

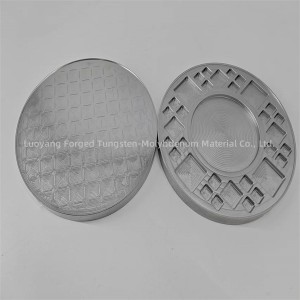

molybdenum wafer molybdenum diamond sheet in CVD

The chemical vapor deposition (CVD) method of diamond involves using a chemical process to synthesize a diamond film or coating in a controlled environment. In this method, a gas mixture, typically containing hydrocarbon gases such as methane, is introduced into a reaction chamber together with a substrate material such as molybdenum wafers or diamond wafers. The gas is then activated by various means, such as heat or plasma, to break down hydrocarbon molecules and deposit carbon atoms onto the substrate, resulting in the growth of diamond crystals.

The CVD process of diamond offers several advantages, including the ability to produce high-quality diamond coatings with precise control of thickness, uniformity and composition. It also allows the deposition of diamond films on a variety of substrate materials, enabling the creation of diamond-coated parts for a variety of industrial and research applications.

Overall, the CVD method of diamond is a versatile and widely used technique for producing synthetic diamond films and coatings with customized properties, making them valuable in industries such as electronics, cutting tools, and wear-resistant coatings.

The hardness of chemical vapor deposition (CVD) coatings can vary depending on the specific materials deposited and the process parameters used. However, CVD coatings are known for their exceptional hardness, often exceeding that of traditional physical vapor deposition (PVD) coatings.

For diamond CVD coatings, hardness is particularly noteworthy. Diamond is one of the hardest materials known, and CVD diamond coatings have exceptional hardness that often exceeds that of other types of coatings. The hardness of CVD diamond coatings is typically measured using the Vickers hardness scale and ranges from 8000 HV to over 10000 HV, making it one of the hardest and most wear-resistant materials.

For other CVD coatings, such as carbide or nitride-based coatings, the hardness can also be high, providing excellent wear resistance and durability in a variety of industrial applications.

Overall, CVD coatings are valued for their exceptional hardness, making them suitable for applications where wear resistance, high-temperature stability, and long-term performance are critical.

Wechat:15138768150

WhatsApp: +86 15838517324

E-mail : jiajia@forgedmoly.com