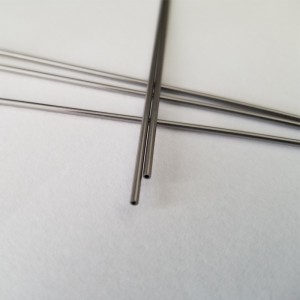

molybdenum round rod for High-temperature sintering and heat treatment industry

Heat treatment of molybdenum typically involves processes that improve its mechanical properties such as ductility, toughness, and strength. The most common molybdenum heat treatment processes include annealing and stress relief:

1. Annealing: Molybdenum is often annealed to reduce its hardness and increase its ductility. The annealing process usually involves heating the molybdenum to a specific temperature (usually around 1200-1400°C) and then slowly cooling it to room temperature. This process helps relieve internal stresses and recrystallize the molybdenum structure, improving ductility and toughness.

2. Stress relief: Molybdenum parts that have undergone extensive cold working or machining can be stress relieved to reduce internal stress and improve dimensional stability. The process involves heating molybdenum to a specific temperature (usually around 800-1100°C) and holding it at that temperature for a period of time before slowly cooling it. Stress relief helps minimize distortion and reduce the risk of cracking of molybdenum components.

It is worth noting that the specific heat treatment process for molybdenum may vary depending on alloy composition, intended application and desired material properties. Therefore, it is recommended to consult a materials expert or refer to specific molybdenum heat treatment guidelines to ensure appropriate treatment for a given application.

The sintering of molybdenum involves the process of compacting molybdenum powder and heating it to a temperature below its melting point, causing the individual powder particles to bond together. This process results in the formation of a solid molybdenum structure with improved strength and density.

The sintering process usually includes the following steps:

1. Powder pressing: Use a mold or die to press molybdenum powder into the desired shape. The compaction process helps form a coherent structure into the powder.

2. Heating: The compacted molybdenum powder is then heated in a controlled atmosphere to a temperature below the melting point of molybdenum. This temperature is usually high enough for the individual powder particles to bond together through diffusion, forming a solid structure.

3. Densification: During the sintering process, the molybdenum structure densifies as individual particles bond together. This results in increased density and strength of sintered molybdenum parts.

Sintering is often used to produce molybdenum components with complex shapes and high density requirements, such as heating elements, furnace components, sintering boats, etc. The process produces strong and durable molybdenum parts with improved mechanical properties suitable for high-temperature applications.

Wechat:15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com