High temperature resistance MLa Wire

Many types of wire are designed to withstand high temperatures, including:

1. Nickel-based alloys: Nickel-based welding wires, such as Inconel and nichrome, are known for their high temperature resistance and are often used in applications that require heat resistance, such as heating elements and industrial furnaces.

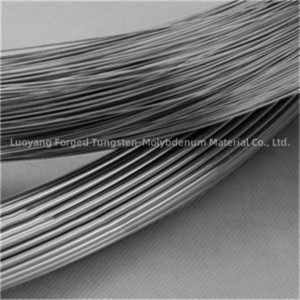

2. Tungsten: Tungsten wire has a very high melting point and is used in high temperature applications such as incandescent light bulbs and heating elements in high temperature furnaces.

3. Molybdenum: Molybdenum wire also has a high melting point and is used in high-temperature applications, including the aerospace and electronics industries.

4. Platinum: Platinum wire is known for its high temperature stability and is used in laboratory equipment, thermocouples and other high temperature applications.

These wires are specifically designed to withstand extreme heat and are used in a variety of industrial, scientific and technical applications that require high temperature resistance.

Generally speaking, hot wire has a higher resistance than cold wire. This is because the resistance of most materials increases with temperature. This relationship is described by the temperature coefficient of resistance, which quantifies how much a material's resistance changes with temperature.

When a wire is heated, the increased thermal energy causes the atoms in the material to vibrate more violently, resulting in greater collisions with the electron stream. This increased atomic vibration hinders the movement of electrons, causing higher resistance to the flow of electricity.

Conversely, as the wire cools, the reduction in thermal energy causes the atoms to vibrate less, thus reducing the resistance to the flow of electricity.

It is worth noting that this relationship between temperature and resistance does not apply to all materials, as some materials may exhibit a negative temperature coefficient of resistance, meaning that their resistance decreases as temperature increases. However, for most common conductive materials, including metals like copper and aluminum, resistance typically increases with temperature.

When wires have high resistance, a variety of effects and consequences can occur, depending on the situation and application. Here are some general results for high resistance wires:

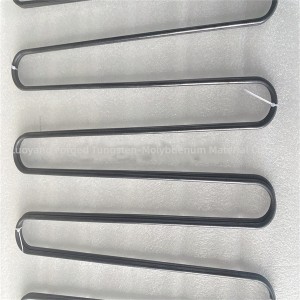

1. Heating: When electric current passes through a high-resistance wire, a large amount of heat is generated. This property can be used in heating elements such as those found in toasters, electric stoves and industrial furnaces.

2. Voltage Drop: In a circuit, high-resistance wires can cause significant voltage drops along the length of the wire. This may affect the performance of the circuit and the operation of connected equipment.

3. Energy loss: High-resistance wires cause energy to be lost in the form of heat, reducing the efficiency of electrical systems and equipment.

4. Reduced Electrical Current: High-resistance wires restrict the flow of electrical current, which can affect the operation of electrical equipment and systems, especially those that require high current levels.

5. Component heating: In electronic circuits, high-resistance connections or components can cause localized heating, affecting the performance and reliability of the circuit.

Overall, the effects of high resistance in wires depend on the specific application and intended function of the wires within the system.

Wechat:15138768150

WhatsApp: +86 15138745597

E-mail : jiajia@forgedmoly.com