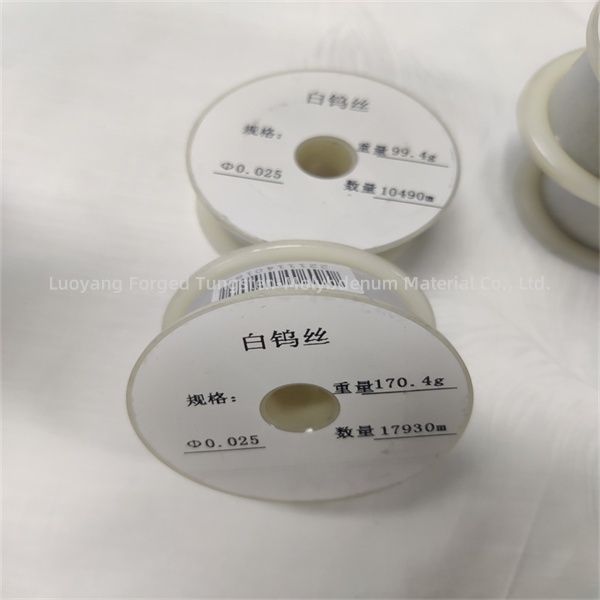

0.025mm tungsten waya 99.95% tungsten filament dị ọcha

Na mgbakwunye na iji ya na bọlbụ ọkụ, a na-eji waya tungsten eme ihe n'ọtụtụ ebe dị ka ihe na-enye ọkụ na ngwaọrụ eletrọnịkị ndị ọzọ dị ka telivishọn, ihuenyo ngosi, lasers, ngwa eletriki na-ekpo ọkụ, na tubes eletrik. Ihe ndị na-emepụta ọkụ tungsten na ngwaọrụ ndị a nwere ike ịmepụta nchapụta dị elu, nkwụsi ike dị mma, na ogologo ndụ ọkụ ọkụ, na-egbo mkpa ngwa dị iche iche.

| Dayameta | Enwere ike ịhazi ya |

| Ebe Mmalite | Henan, Luoyang |

| Aha ika | FGD |

| Ngwa | Medical, Heating element, ụlọ ọrụ |

| Ụdị | Kwụ ọtọ |

| Elu | Achachapụrụ |

| Ịdị ọcha | 99.95% Nkeji |

| Ihe onwunwe | Dị ọcha W |

| Njupụta | 19.3g / cm3 |

| MOQ | 1 n'arọ |

| Dayameta nke silk ihe onwunwed, μm | Ibu nke akụkụ silk 200mm, mg | Ogologo kacha nta, m |

| 5≤d≤10 | 0.075-0.30 | 300 |

| 10≤d≤60 | >0.30-10.91 | 400 |

| 60.d≤100 | >10.91-30.30 | 350 |

| 100.d≤150 | >30.30-68.18 | 200 |

| 150.d≤200 | >68.18-121.20 | 100 |

| 200.d≤350 | >121.20-371.19 | 50 |

| 350.d≤700 | / | Dakọtara na ogologo 75g n'ịdị arọ |

| 700.d≤1800 | / | Dakọtara na ogologo 75g n'ịdị arọ |

| Dayameta nke silk ld, μm | Ibu nke akụkụ silk 200mm, mg | Ibu nke 200mm akụkụ silk deviation | Ngbanwe dayameta % | |||

| 0 ọkwa | m larịị | II ọkwa | m larịị | II ọkwa | ||

| 5≤d≤10 | 0.075-0.30 | / | ±4 | ±5 | / | / |

| 10≤d≤18 | 0.30 ~ 0.98 | / | ±3 | ±4 | / | / |

| 18≤d≤40 | 0.98-4.85 | ±2 | ±2.5 | ±3 | / | / |

| 40 d≤80 | 4.85-19.39 | ±1.5 | ±2.0 | ±2.5 | / | / |

| 80d≤300 | 19.39-272.71 | ±1.0 | ±1.5 | ±2.0 | / | / |

| 300d≤350 | >272.71~371.19 | / | ±1.0 | ±1.5 | / | / |

| 350d≤500 | / | / | / | / | ±1.5 | ±2.0 |

| 500 d≤1800 | / | / | / | / | ±1.0 | ±1.5 |

1. Ụlọ ọrụ anyị dị na Luoyang City, Henan Province. Luoyang bụ mpaghara mmepụta maka tungsten na molybdenum mines, yabụ anyị nwere uru zuru oke na ịdị mma na ọnụahịa;

2. Ụlọ ọrụ anyị nwere ndị ọrụ nkà na ụzụ nke nwere ahụmahụ karịrị afọ 15, anyị na-enyekwa ngwọta na aro ezubere iche maka mkpa onye ahịa ọ bụla.

3. Ngwaahịa anyị niile na-enyocha nyocha nke ọma tupu ebupụ ya.

4. Ọ bụrụ na ị nweta ngwongwo ndị na-adịghị mma, ị nwere ike ịkpọtụrụ anyị maka nkwụghachi.

1.Mwepu nke akụrụngwa

2.chemical ọgwụgwọ

3. Mbelata na ntụ ntụ tungsten

4.Ppressing na sintering

5. Ịse

6.Annealing

7. ọgwụgwọ elu

8. njikwa mma

9. Nkwakọ ngwaahịa

1. Ngwa eletrọnịkị na akụrụngwa na-ekpo ọkụ: A na-eji waya Tungsten dị ka ihe na-ekpo ọkụ na-ekpo ọkụ maka egbe eletrọn na-ekpo ọkụ na ngwa ndị dị otú ahụ. A na-ejikarị ha eme ihe na akụrụngwa na-ekpo ọkụ dị ka tubes elektrọn na-ekpo ọkụ, microscopes eletrọn, na ngwaọrụ ionization gas.

2. Ogige ọkụ: N'ihi ike ya na-ebunye ọkụ na-egbuke egbuke na okpomọkụ dị elu na nkwụsị ya na nkwụsị, a na-eji waya tungsten eme ihe dị ka isi iyi ọkụ na omenala incandescent bulbs.

3. Igwe ọkụ na-eguzogide: Ebe mgbaze dị elu na oke okpomọkụ nke waya tungsten na-eme ka ọ bụrụ ihe dị mma maka ikpo ọkụ ọkụ. A na-ejikarị ha eme ihe n'ụlọ na ụlọ ọrụ mmepụta ihe ọkụ eletrik dị ka stovu eletrik, oven, na ígwè.

4. Ịgbado ọkụ na ịkpụ: Tungsten waya na-ejikarị dị ka electrode ihe na elu-ike ịgbado ọkụ na igbutu usoro dị ka argon arc ịgbado ọkụ, laser ọnwụ, na electron beam ịgbado ọkụ. Ebe mgbaze ya dị elu na nguzogide corrosion na-eme ka ọ bụrụ ezigbo nhọrọ maka mmalite arc na ntọhapụ ugbu a na usoro ndị a.

5. Chemical reactors: Na ụfọdụ chemical reactors, tungsten wires na-eji dị ka ihe na-akwado na-akwado ihe iji melite mmeghachi omume arụmọrụ na nkwụsi ike.

Na mgbakwunye na ngwa ndị a dị n'elu, a na-ejikwa waya tungsten na ụlọ ọrụ akwa, ikuku ikuku, ụlọ ọrụ nuklia na mpaghara ahụike.

Ekwesịrị ikpebi dayameta nke waya tungsten dị ka ihe ngosi ngwa akọwapụtara si dị. N'ikwu okwu n'ozuzu, ka dayameta dị mma, obere ike na ịdọka waya tungsten ga-enwe, mana ikike ibu ibu na ndụ ọrụ ga-ebelata otu ahụ. Ya mere, ọ dị mkpa ịhọrọ dị ka mkpa kpọmkwem.

Ihe nke waya tungsten nwere mmetụta dị ukwuu na ngwa ya. Tungsten dị ọcha nwere ike okpomọkụ dị elu na nguzogide corrosion karịa tungsten alloy. Ya mere, n'ọnọdụ ebe a chọrọ ịdị ọcha dị elu na nguzogide corrosion dị elu, a na-atụ aro ka ịhọrọ waya tungsten dị ọcha; Tungsten alloy nwere ike na ductility ka mma, na-eme ka ọ dabara maka ụfọdụ ngwa pụrụ iche dị ka igwe ọkụ ọkụ, ngwa eletriki oghere na mpaghara ndị ọzọ.

Oge agbaze nke waya tungsten na-ekpo ọkụ n'ime oghere na-adabere n'ọnụego evaporation nke tungsten. Na ikpo ọkụ nke tungsten waya na ikuku na-emepụta tungsten oxide. Ebe mgbaze nke tungsten bụ 3410 degrees. Ebe mgbaze nke tungsten oxide, WO3, bụ 1400-1600 degrees. N'okpuru ọnọdụ ọrụ nkịtị, okpomọkụ nke filament dị gburugburu 2500 degrees, na WO3 ngwa ngwa vaporize na okpomọkụ a, na-eme ka filament na-agbaze ngwa ngwa na ikuku.