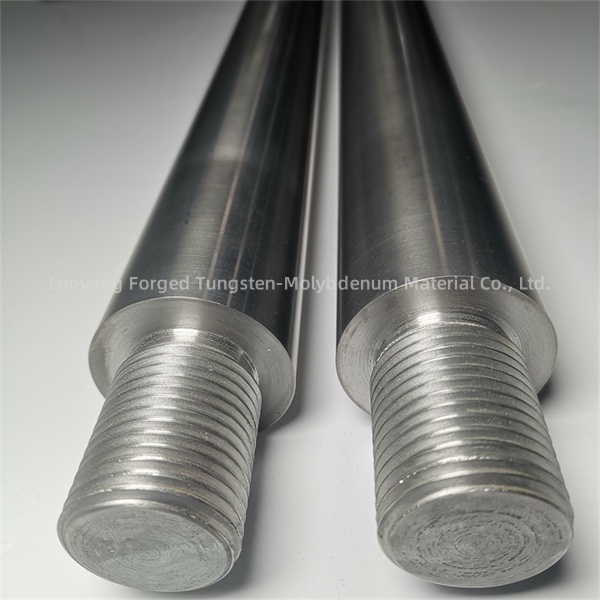

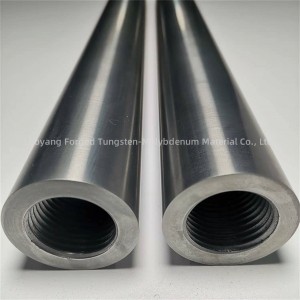

W1 ntshiab tungsten electrode bar rau vuam

Tungsten electrode pas nrig yog ib hom electrode pas nrig nrog cov yam ntxwv xws li siab melting point, siab ceev, siab hardness, thiab tsawg thermal expansion coefficient. Yog li ntawd, nws yog dav siv nyob rau hauv electrode ua hauj lwm nyob rau hauv high-temperature cheeb tsam. Ntawm lawv, tungsten oxide electrode rods yog dav siv nyob rau hauv cov txheej txheem teb xws li argon arc vuam thiab plasma txiav vim lawv lub neej ntev kev pab cuam thiab zoo oxidation kuj.

| Qhov ntev | Raws li koj cov duab kos |

| Qhov Chaw Keeb Kwm | Luoyang, Henan |

| Hom Lub Npe | FGD |

| Daim ntawv thov | Kev lag luam |

| Nto | Polished |

| Purity | 99.95% |

| Khoom siv | Ntshiab tungsten |

| Qhov ntom | 19.3g / cm3 |

| melting point | 3400 ℃ |

| Kev siv ib puag ncig | Nqus ib puag ncig |

| Kev siv kub | 1600-2500 ℃ |

| Cov khoom tseem ceeb | W ≥ 99.95% |

| Cov ntsiab lus impurity ≤ | |

| Pb | 0.0005 |

| Fe | 0.0020 Nws |

| S | 0.0050 Nws |

| P | 0.0005 |

| C | 0.01 ib |

| Cr | 0.0010 Nws |

| Al | 0.0015 Nws |

| Cu | 0.0015 Nws |

| K | 0.008 0 |

| N | 0.003 ib |

| Sn | 0.0015 Nws |

| Si | 0.0020 Nws |

| Ca | 0.0015 Nws |

| Na | 0.0020 Nws |

| O | 0.008 ib |

| Ti | 0.0010 Nws |

| Mg | 0.0010 Nws |

1. Peb lub Hoobkas nyob hauv Luoyang City, Henan Province. Luoyang yog thaj chaw tsim khoom rau tungsten thiab molybdenum mines, yog li peb muaj qhov zoo ntawm qhov zoo thiab tus nqi;

2. Peb lub tuam txhab muaj cov kws tshaj lij nrog ntau tshaj 15 xyoo kev paub, thiab peb muab cov kev daws teeb meem thiab cov lus qhia rau txhua tus neeg siv khoom xav tau.

3. Tag nrho peb cov khoom raug soj ntsuam nruj ua ntej xa tawm.

4. Yog tias koj tau txais cov khoom tsis raug, koj tuaj yeem tiv tauj peb kom them rov qab.

1. Kev sib xyaw ntawm cov khoom xyaw

2. xovxwm tsim

3. Sintering infiltration

4. txias-ua hauj lwm

Aerospace, metallurgy, machinery thiab lwm yam lag luam: Tungsten electrode rods kuj tau siv dav hauv aerospace, metallurgy, machinery thiab lwm yam lag luam rau kev tsim cov khoom kub-resistant, hluav taws xob alloys, hluav taws xob machining electrodes, microelectronic cov ntaub ntawv, thiab lwm yam. tsis tshua muaj siab precision thiab kev ntseeg tau.

Tsis tas li ntawd, tungsten electrode rods kuj tseem siv rau kev tsim cov filaments thiab kev kub ceev txiav ntawm cov hlau alloy, superhard pwm, thiab rau kev tsim cov khoom siv kho qhov muag thiab tshuaj. Hauv kev ua tub rog, tungsten electrode rods kuj muaj cov ntawv thov tseem ceeb.

Qhov no feem ntau yog vim muaj ntau dhau tam sim no, tshaj qhov tso cai tam sim no ntawm tungsten electrode; Kev xaiv tsis raug ntawm tungsten electrodes, xws li txoj kab uas hla tsis sib xws lossis qauv; Kev sib tsoo tsis raug ntawm tungsten electrodes ua rau melting; Thiab cov teeb meem nrog cov txheej txheem vuam, xws li kev sib cuag tsis tu ncua thiab ignition ntawm tungsten cov lus qhia thiab cov ntaub ntawv hauv paus, ua rau kom nrawm hnav thiab tsim kua muag.

1. Cov av los yog oxidation: Cov conductivity ntawm tungsten txo qis raws li qib ntawm oxidation ntawm nws qhov chaw nce. Yog hais tias thaj tsam ntawm tus pas nrig tungsten accumulates ntau cov av los yog tsis huv rau ntev, nws yuav cuam tshuam rau nws cov conductivity.

2. Tsawg purity: Yog hais tias muaj lwm yam impurity hlau nyob rau hauv cov khoom ntawm tungsten pas nrig, lawv yuav txwv tsis pub khiav ntawm tam sim no thiab ua rau lub pas nrig tungsten tsis yog conductive.

3. Tsis sib xws sintering: Thaum lub sij hawm tsim cov txheej txheem ntawm tungsten rods, sintering yuav tsum tau. Yog hais tias lub sintering tsis sib npaug, cov kev tsis zoo tshwm sim tuaj yeem tshwm sim rau ntawm qhov chaw, uas tuaj yeem ua rau txo qis ntawm cov tungsten pas nrig.